www.ptreview.co.uk

01

'24

Written on Modified on

YASKAWA LAUNCHES YRM CONTROLLER YRM1010

YRM1010 improves processing performance and communication for a variate production.

YRM Controller YRM1010

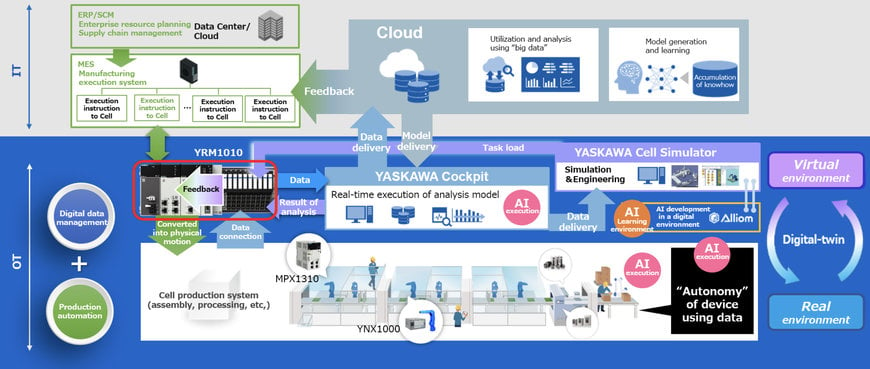

Yaskawa has been promoting a new solution concept called i³-Mechatronics since 2017, in which digital data management is added to existing automation solutions, with the aim of realizing a new industrial automation revolution, as set forth in its long-term business plan “VISION 2025”. The company launched a new controller solution called “iCube Control”. As a first step, it developed and started sales of the YRM controller YRM1010, which enables integrated control of so-called cells composed of equipment and industrial robots, while simultaneously collecting and utilizing highly synchronous data in real-time for feedback. This is a further improvement in the performance and functionality of the YRM-X (ten) controller (YRM1000), the first YRM controller, released in 2021.

Aim of Commercializing YRM1010

Various manufacturing sites are making efforts to advance smart factories by improving production efficiency and quality, as well as ensuring traceability through the use of IoT and AI. Fundamental to these activities is the understanding of the operating status by digital data of production facilities. In order to improve the production efficiency of facilities, it is necessary to collect integrated and time-series data from the various equipment that comprise a cell, and then feed the results back to the production facilities based on such highly accurate data.

Yaskawa developed the YRM Controller, which enables integrated cell control and time-series data collection. By linking with YASKAWA Cockpit (YCP), a data capture tool that collects and analyzes data at once, it is possible to feed the results of real-time analysis back to the motion of cells. This allows the entire control of cells based on data.

With YRM1010, it will further promote the realization of i³-Mechatronics, and strengthen its ability to solve problems and provide added value to its customers.

Yaskawa has been promoting a new solution concept called i³-Mechatronics since 2017, in which digital data management is added to existing automation solutions, with the aim of realizing a new industrial automation revolution, as set forth in its long-term business plan “VISION 2025”. The company launched a new controller solution called “iCube Control”. As a first step, it developed and started sales of the YRM controller YRM1010, which enables integrated control of so-called cells composed of equipment and industrial robots, while simultaneously collecting and utilizing highly synchronous data in real-time for feedback. This is a further improvement in the performance and functionality of the YRM-X (ten) controller (YRM1000), the first YRM controller, released in 2021.

Aim of Commercializing YRM1010

Various manufacturing sites are making efforts to advance smart factories by improving production efficiency and quality, as well as ensuring traceability through the use of IoT and AI. Fundamental to these activities is the understanding of the operating status by digital data of production facilities. In order to improve the production efficiency of facilities, it is necessary to collect integrated and time-series data from the various equipment that comprise a cell, and then feed the results back to the production facilities based on such highly accurate data.

Yaskawa developed the YRM Controller, which enables integrated cell control and time-series data collection. By linking with YASKAWA Cockpit (YCP), a data capture tool that collects and analyzes data at once, it is possible to feed the results of real-time analysis back to the motion of cells. This allows the entire control of cells based on data.

With YRM1010, it will further promote the realization of i³-Mechatronics, and strengthen its ability to solve problems and provide added value to its customers.

Key Features of YRM1010

- Data collecting in a cell: It defines a cell, and integrates and collects data of equipment and industrial robots in the cell, and automatically stores it in YCP at the same time.

- Feedback data analyzed by YCP to control: The results of YCP data analysis are fed back to the YRM controller. It will be reflected to improve the moving ratio of cells and the product quality.

- Autonomous distribution based on data in cells: New “bulletin board” functions to centrally manage data in cells. The YRM1010 provides not only sequential control, but also control in which equipment and industrial robots autonomously make judgements based on the “bulletin board” and change them into motion. It contributes to the realization of variate production.

Performance/functionality

- Improvement of processing performance: Approximately 1.5 times higher processing performance than YRM1000.

- Enhanced communications: MECHATROLINK, which can be switched between MECHATROLINK-4 and III, allows up to 128 stations to be connected. It also supports Ethernet/IP (1 Gbps) and can connect up to 64 stations.

- SLIO I/O series support: By directly attaching the various types of SLIO I/Os to the YRM1010, various systems can be set up. SLIO I/O also can be distributed as remote I/O by using bus couplers for various networks such as MECHATROLINK-4.

Product Positioning