www.ptreview.co.uk

08

'22

Written on Modified on

Pepperl+Fuch's role in making hydrogen the Keystone of the energy transition

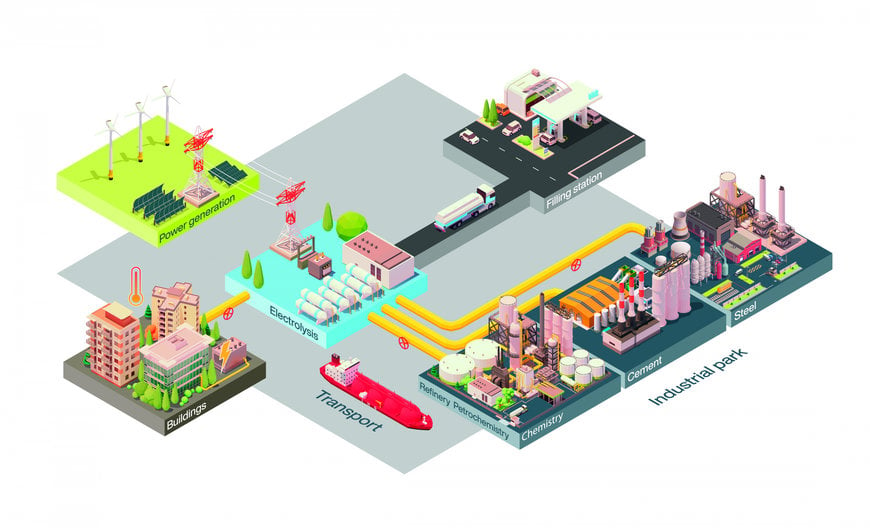

Anyone who wants to curb climate change will not be able to avoid hydrogen. The first element of the periodic table is a key factor in decarbonizing transport and industry—provided that the gas has been extracted without CO2 emissions. The value chain from the wind turbine to the hydrogen filling station is long, and it is replete with technical challenges.

Decarbonization will bring about numerous changes, especially in the way we generate, store, distribute, and consume energy. "Green" hydrogen will play a fundamental role in producing energy and decarbonizing industry and heavy-duty vehicles in the future. To ensure that automated processes are safe, explosion-protected components and sensors with a variety of different functions are required.

Pepperl+Fuchs has many years of experience in the field of explosion protection and industrial sensor technology, making it the right partner and a binding element in the hydrogen chain—from generating renewable energy, high-pressure compression after electrolysis, transport, and storage through to large-scale industrial use and hydrogen filling stations.

Pepperl+Fuchs offers the right sensors and components for explosion protection along the entire hydrogen value chain.

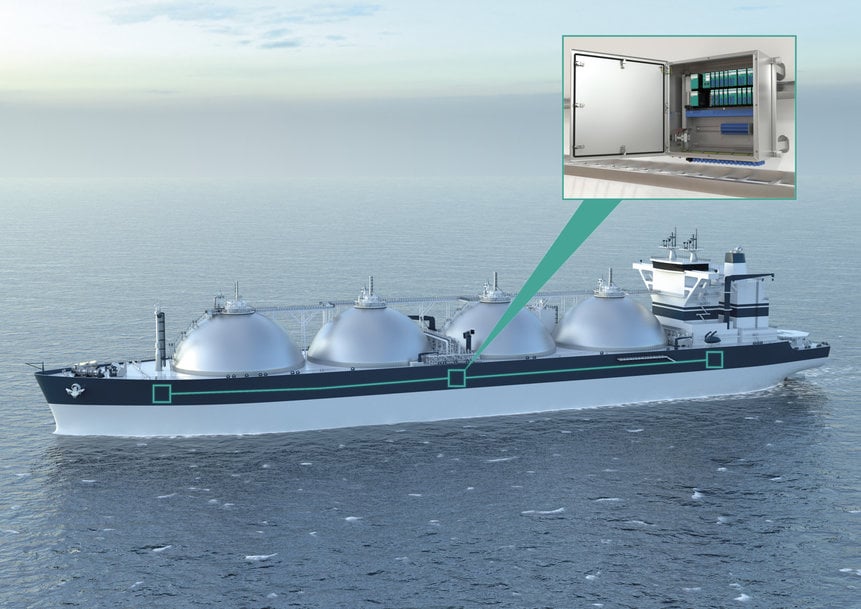

As with LNG (Liquified Natural Gas), explosion protection components such as the Remote I/O or purge and pressurization systems ae used when transporting liquid hydrogen.

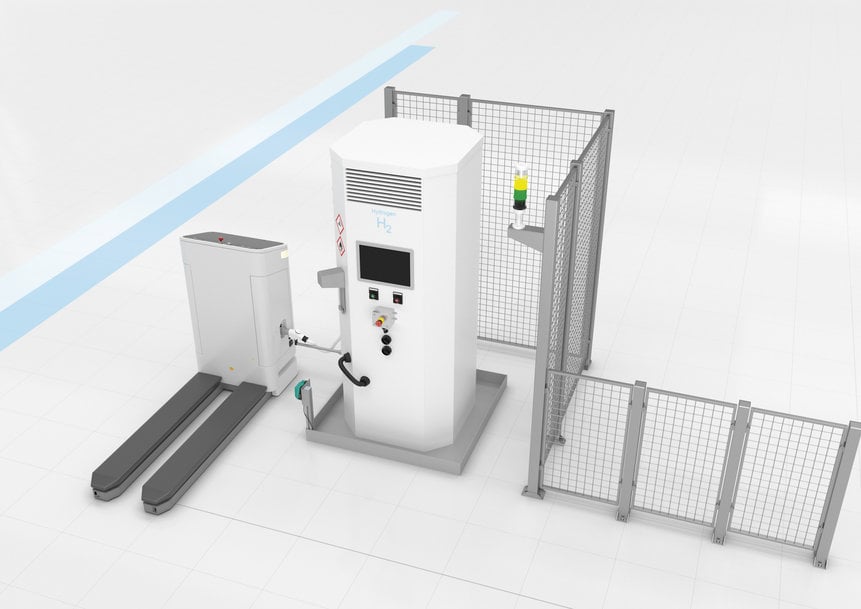

RFID components ensure reliable tank identification. A high-resolution monitor of VisuNET FLX series guides through the fueling process.