www.ptreview.co.uk

25

'22

Written on Modified on

Modular Design for Maximum Flexibility

The modular platforms of the HMI portfolio from Pepperl+Fuchs offer individual solutions for applications ranging from non-hazardous areas to Zone 1.

Modular design of VisuNet FLX

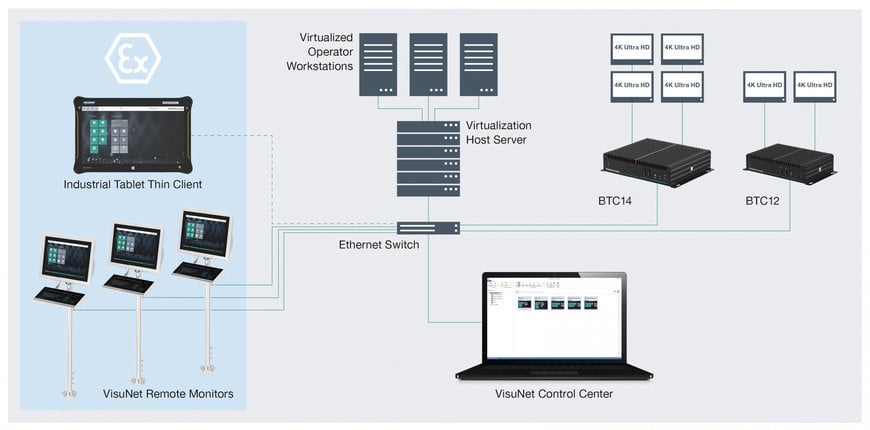

The VisuNet GXP and VisuNet FLX HMI device families enable maximum flexibility for use in the process industry. The modular design allows HMI systems to be configured to meet precise individual needs, providing extremely quick, simple service options in the field. This means that a comprehensive range of technologies, installation options, and peripherals is available for customers. Each HMI system consists of at least one computer unit and one display unit, each of which can be individually configured. The operator workstations from Pepperl+Fuchs are designed and certified for use in ATEX/IECEx Zone 1/21, Zone 2/22, and Div 1 applications. In addition, all products can be used in non-hazardous areas.

The VisuNet RM Shell 5 firmware developed by Pepperl+Fuchs for VisuNet thin clients is based on Windows 10 IOT 2019 LTSC and offers a simple way to make individual adjustments. The highest safety standards and flexible configuration options allow connection to numerous virtualized and conventional process control systems.

End-to-end thin client portfolio up to Zone 1/21

The product range is rounded off by rugged box thin clients for use in control rooms and switch cabinets. In addition, mobile tablet thin clients from Pepperl+Fuchs ensure a complete portfolio for virtualized and conventional process control systems. With the VisuNet Control Center software, the thin clients can be managed seamlessly and centrally — from Zone 1 to the control room.