Real-time communication via 5G with Profinet

Siemens enables the transmission of Profinet IO via a private 5G network, which allows data to be transmitted in real time for industrial applications.

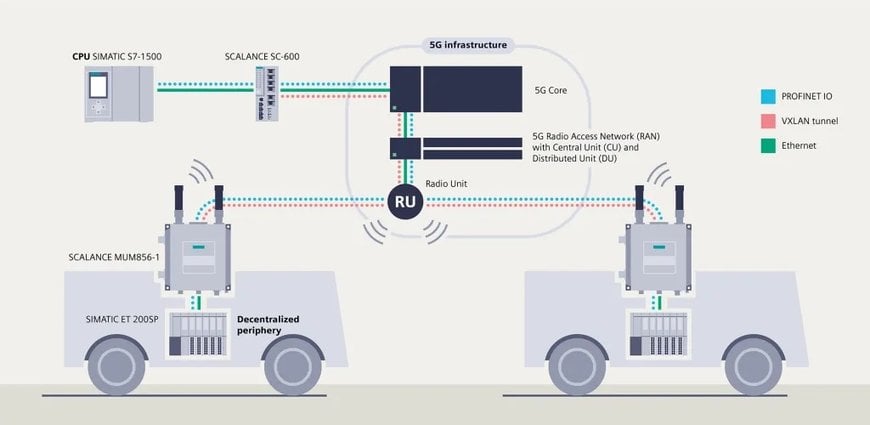

Thanks to the VXLAN transmission technology, the Profinet IO protocol can be used for communication over a private 5G network. This enables real-time communication and the use of a central control system for several mobile participants.

- Transmission of Profinet IO packets via a private 5G network

- VXLAN as transmission technology embeds Profinet protocol

- Use of a central control system for multiple mobile participants reduces energy and maintenance costs

This is made possible by the VXLAN (Virtual Extensible LAN) transmission technology in the Scalance 5G routers and security appliances from Siemens. VXLAN embeds the Profinet IO protocol, which is transmitted in Layer 2, into Layer 3 packets, which allows them to be transmitted across network boundaries. Since Layer 2 communication now takes place via 5G, a central controller can communicate with decentralized I/O modules on mobile devices such as automated guided vehicles (AGVs) via Profinet in a private 5G network and no local controls have to be used on the individual AGVs. This saves costs and reduces maintenance. At the Hannover Messe, visitors can see this innovation at the booth of the organization "5G-ACIA" in Hall 9.

Industrial 5G at the Hannover Messe

At the booth in Hall 9, Siemens will also be showcasing the connection of automated guided vehicles via 5G in a prototype of a private industrial standalone 5G network. Mobile participants in production facilities, such as Automated guided vehicles (AGVs) in intralogistics and mobile robots increase flexibility in production and require reliable wireless communication for smooth and safe operation.

With the Scalance MUM853-1, Siemens is exhibiting its industrial 5G router for the control cabinet at the trade fair. The device connects local industrial applications with public 5G and 4G (LTE) mobile networks. With the router, plants, machines, controls and other industrial devices can be monitored and maintained remotely via a public mobile network at high data rates. In addition, the device can be integrated into private 5G networks. The Scalance MUM853-1 thus enables trend-setting applications such as mobile robots in production or autonomous vehicles in logistics.

First tests in the private 5G test field at the trade fair

Deutsche Messe and Siemens are giving all companies access to innovative Industrial 5G technology at the "5G Smart Venue" in Hanover. Companies can test their applications in a prototype of a private Industrial 5G standalone test network based on Release 15. This is an industrial 5G network that uses the spectrum for campus networks available in Germany (3.7 – 3.8 GHz band). The first companies are already testing the network, for example the industrial ICT company HMS Networks has integrated sensors into the infrastructure via a controller and a 5G router.

"The integration of our devices into the Siemens network was very easy," says Dr. Jens Jakobsen, Head of Development at HMS Labs. Frank Hakemeyer, Director Communication Interfaces at Phoenix Contact, adds: "Within Siemens' private 5G network, we will be demonstrating at the Hannover Messe how our industrial 5G router can now also transmit security-relevant signals via mobile communications. Commissioning our 5G router within the Siemens network was particularly easy."

Siemens is developing its own 5G ecosystem, which consists of a 5G infrastructure for private 5G networks and end devices. The 5G infrastructure is still under development and will be available in 2023.

Further information on 5G can be found at: www.siemens.com/industrial-5G

Further information on Siemens at Hannover Messe please see www.siemens.com/press/hm and www.siemens.com/hm.

www.siemens.com