www.ptreview.co.uk

29

'26

Written on Modified on

Servo Drive with Integrated Extended Functional Safety

Festo introduces the CMMT-AS-MP-S3 servo drive, combining motion control and extended safety functions in a compact architecture.

www.festo.com

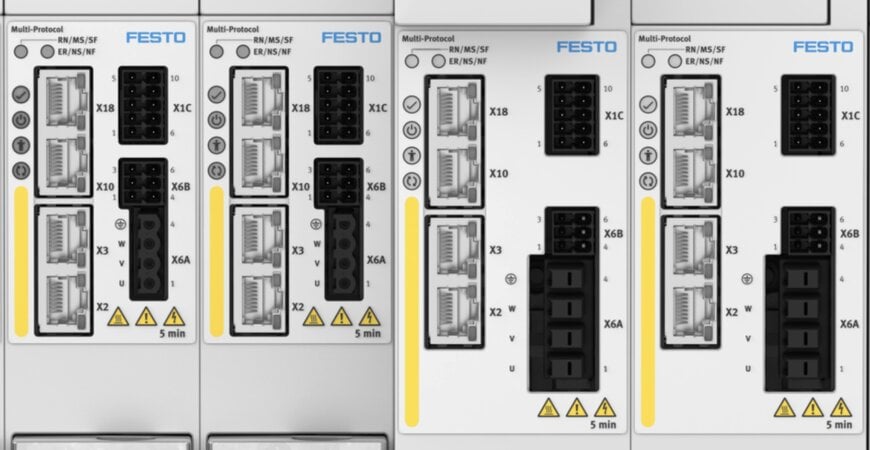

Festo has expanded its electric automation portfolio with the CMMT-AS-MP-S3 servo drive, a solution that integrates high-performance motion control and extended functional safety in a single device for demanding industrial automation applications.

Integrated motion control and safety architecture

The CMMT-AS-MP-S3 builds on the established CMMT-AS servo drive platform, extending it with integrated functional safety features designed to simplify machine design and commissioning. By combining motion control and safety functions in one compact unit, the drive eliminates the need for external safety modules or additional wiring, reducing system complexity, cabinet space requirements, and overall integration effort.

The servo drive is intended for applications where safety and precision must coexist, including assembly and handling systems, packaging machinery, and electronics manufacturing equipment.

Functional safety capabilities and compliance

The CMMT-AS-MP-S3 supports safety levels up to Performance Level e (PL e), SIL 3, and Categories 3 and 4, aligning with the highest requirements for machinery safety.

Integrated safety functions enable both linear and rotary motion applications to be implemented with extended safety, in combination with the full range of Festo mechanical components. The drive covers a power range from 300 W to 12 kW, supporting a wide variety of machine sizes and duty profiles.

Connectivity and automation integration

The servo drive supports multiple Ethernet-based industrial communication protocols, including EtherCAT, EtherNet/IP, PROFINET, and Modbus TCP. This multi-protocol capability allows the CMMT-AS-MP-S3 to integrate into diverse automation architectures without changes to higher-level control systems.

Seamless compatibility with Festo’s pneumatic and electric automation portfolio enables consistent system design across hybrid machines, where electric motion and pneumatic functions are combined.

Commissioning and engineering with Festo Automation Suite

Safety parameters can be set directly on the device without software, supporting basic configuration and rapid deployment. For more complex applications, the servo drive can be programmed and commissioned using the Festo Automation Suite (FAS).

FAS provides a graphical, guided workflow for safety setup, validation, commissioning, diagnostics, and firmware updates. Preset parameter values and step-by-step validation routines are designed to shorten commissioning time and reduce configuration errors. The software also supports I/O and fieldbus configuration, as well as the generation of validation documentation for functional safety compliance.

Application context

As machinery becomes more compact and flexible, integrating extended safety directly into drive technology is increasingly important. The CMMT-AS-MP-S3 addresses this requirement by consolidating motion and safety functions into a single, standards-compliant servo drive.

For machine builders and system integrators, the approach offers a way to achieve high safety levels while minimizing hardware complexity, supporting faster commissioning, and maintaining performance across a broad range of automated manufacturing applications.

www.festo.com