www.ptreview.co.uk

04

'25

Written on Modified on

Festo adds first edge device to AX operating system

CEPE is a high-performance industrial PC and control unit designed for industrial motion and IoT applications.

www.festo.com

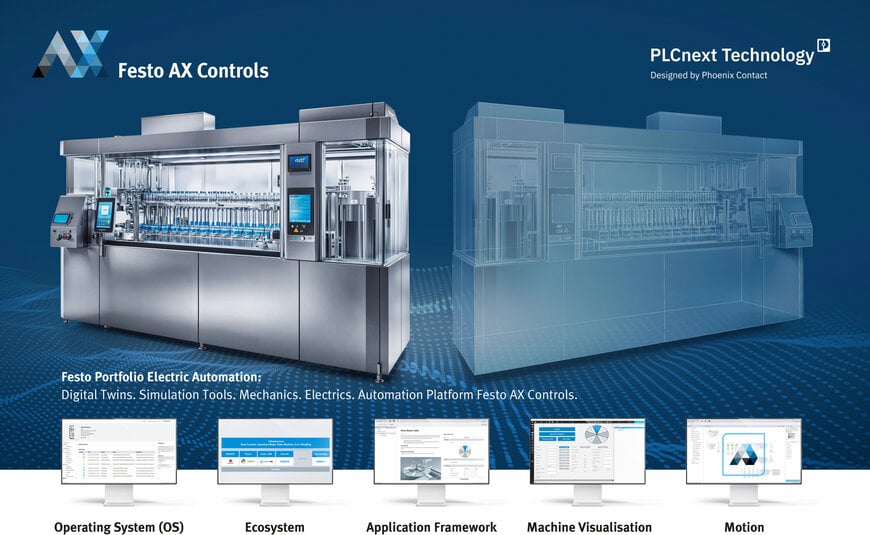

Festo has added the first edge device to its range of AX Controllers. CEPE is a high-performance industrial PC and control unit designed for industrial motion and IoT applications. It uses the Festo AX operating system (OS), which is based on PLCnext Technology and offers an open ecosystem for modular automation and easy programming.

CEPE is designed to control and automate assembly lines and machines, as well as production processes. Highly configurable, CEPE enables the programming and monitoring of production processes, including motion applications such as pick & place, palletising and servo presses. It can also support machine visualisation and IOT data acquisition and analysis.

Festo AX Controls combines many software modules, such as operating system, motion, visualisation, high-level languages and low code development tools through to commissioning software with a scalable hardware platform. The AX suite consists of the Festo AX OS, Festo AX Motion control software, Festo AX Machine Visualisation software and now the CEPE edge controller.

Easy integration

CEPE combines high processing power with a wide range of interfaces and software functions. It can gather and analyse local data, program its own applications and install third-party applications via various app stores. Thanks to its Linux-based operating system, users are also free to develop their own applications using familiar platforms like C++, C#, Python or the IEC61131 family.

Equipped as standard with an Intel i3 processor and a wide range of communication interfaces such as Profinet, Ethernet/IP and EtherCAT or Festo's own AP network, the CEPE edge controller can be optimally connected to different control architectures. Festo's entire electrical and pneumatic portfolio can be seamlessly integrated using this device, so customers can always use the right technology for their application. OPC UA is included for secure, cross-platform and interoperable data exchange in industrial automation and control systems. Combining industry-proven hardware with open control architecture, the CEPE offers many development options for different software applications.

Wider benefits of Festo AX

Festo AX OS is based on PLCnext technology from Phoenix Contact. Developed specifically for industrial environments, it enables real-time applications, programming with modern programming languages and seamless cloud connectivity. The containerised runtime environment enables an open and modular software architecture and the integration of modern AI-based software, as well as robust cybersecurity. This creates the basis for accessing, evaluating, archiving and reusing valuable process data.

Festo AX Controls amplifies these benefits, enabling users to develop individual solutions and seamlessly integrate existing systems to meet the requirements of various industrial applications. Development cycle efficiency can also be increased through the use of open source software and apps, with no limits to future extensions.

Festo already provides a wide selection of apps, including CODESYS, Multi-axis motion, Python, Node-RED and the proprietary Festo AX Industrial Intelligence, a powerful AI predictive maintenance tool. All these software apps and licences will be available via the Festo online catalogue or for purchase via the growing PLCnext Store in future.

www.festo.com