www.ptreview.co.uk

01

'25

Written on Modified on

Intelligent and high-performance drive solutions for the plastics industry at K 2025

Baumüller presents drive solutions in Hall 11 for electrification, digitalization, and efficiency – a partner to leading machine builders in film production, injection molding, extrusion, and recycling.

www.baumueller.com

Under the motto “The Power of Plastics! Green – Smart – Responsible,” visitors from around the world will have the opportunity to explore topics such as circular economy, digitalization, and the responsible, sustainable use of plastics across the entire life cycle from October 8–15, 2025 at the K trade fair in Düsseldorf.

The drive as the heart of all production systems is the specialty of the Baumüller Group, which will be presenting its solutions in Hall 11, Booth E45. As a drive system partner, Baumüller supports numerous machine builders across various industries on their path toward electrification, digitalization, and more efficient processes. Baumüller’s customers include market leaders in the fields of film production, injection molding, extrusion processes, thermoforming, blow molding, and recycling.

Electrification on the rise – intelligent injection control in the drive

Baumüller offers a broad portfolio of solutions for the intelligent control and electrification of hybrid and fully electric plastics machines. At the trade fair, a demonstrator will show how an electric injection molding machine benefits from intelligent servo drive technology in combination with dynamic servo motors.

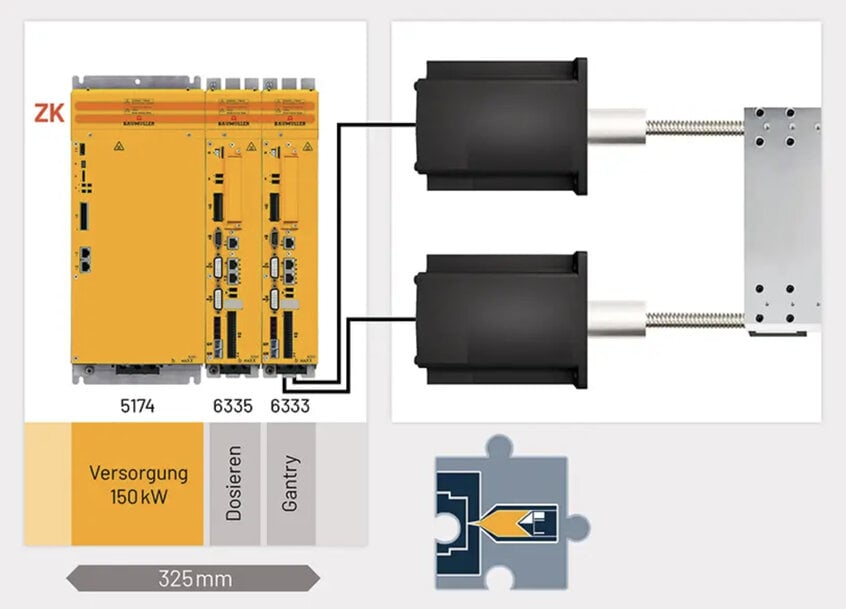

The injection motion is illustrated using two gantry axes. Injection control is computed directly in the servo drive with a cycle time of 125 µs, eliminating fieldbus latency caused by communication with the central machine controller. This leads to greater accuracy in the core process of injection. In multi-layer applications in particular, the load on the machine controller is also reduced. Communication between the two gantry axes occurs at high speed, This allows the force to be divided uniformly and controlled very precisely.

Even in the event of errors, both axes always act synchronously, i.e. performing the same movements at the same time. helping to avoid mechanical damage through highly dynamic fault management. The in-drive injection control is also available for single-axis injection systems.

Intelligent injection control and gantry function.

Servo-hydraulic drive system with patented actual pressure estimator

Baumüller’s servo-hydraulic drive solution consists of a pump, a servo motor, and a servo drive with integrated servo pump control and associated software functions. High-performance servo drives of the b maXX 6500 series regulate the pressure in the hydraulic system using a software function, by adjusting the constant pump through highly dynamic speed control of the servo motor. This drive solution delivers the required pressure and flow values to the machine quickly, precisely, and demand compliant. Compared to fixed speed controlled pumps running directly on the power supply, this leads to a significant reduction in energy consumption.

New: Patented actual pressure estimator

Even in tricky fault scenarios, such as EMC interference, incorrect parameterization, or improperly wired pressure sensors, the Baumüller software detects errors reliably. Unlike conventional wire-break monitoring, which only responds to a missing signal offset, the new patented actual pressure estimator software function can detect implausible pressure sensor signals independently of their signal level. Thanks to a detailed servo-hydraulic model calculated in real time within the servo drive, the system pressure can be estimated based on current and speed.

To further increase machine availability, the estimated actual pressure value can be used in the event of a fault to enable sensorless control with reduced performance. This reduces downtime, since the machine can complete its cycle and move to the ideal service position, even with a sensor defect. Baumüller will present this use case and other intelligent drive functions for servo-hydraulics at the K.

The new generation of DSC2 motors covers a speed range from 1,000 to 5,000 rpm. Compared to conventional servomotors, they are up to 15 percent more compact. The optional direct pump attachment makes the motor-pump unit even more space-saving.

Powerful drive package for more performance and energy efficiency in servo hydraulics

The new mono devices of the b maXX 6500 family are even more compact due to their high-power density and are characterized by their high scalability. This enables even smaller control cabinets or fewer control cabinets overall.

With the DS4 motor generation, Baumüller is setting new standards in terms of compact and powerful main drives. The motor has a high efficiency of over 95 percent, and its compact design enables a further reduction in the machine footprint.

Intelligent machine protection through shock detection

A particular strength of the Baumüller Group is Drive Intelligence: the integration of numerous functionalities directly into the servo drive. A machine protection function was developed especially for plasticizing drives and recycling machines, which ensures that an overload or blockage is prevented if foreign bodies enter the screw or shredding shaft. Early shock detection, for example, protects any feather key connections and the gearbox, thereby extending the service life of the mechanics. This increases machine availability and productivity. Thanks to the drive-integrated implementation, the function achieves particularly short reaction times. This solution represents an economic alternative to the use of overload clutches.

Efficient energy monitoring

Baumüller will also present drive-integrated energy monitoring, which allows software-based measurement of the energy consumption of individual axes, such as the clamping unit, the electric screw drive, or the injection axis. This eliminates the need for power meters and optimizes the system’s overall cost-efficiency.

Highly dynamic clamping motion thanks to the new DST3 torque motor generation

The new, ultra-dynamic DST3 torque motor allows the clamping unit to open and close more quickly and in a more controlled manner. The reason for this is its optimized power density and improved dynamics, combined with smooth running characteristics. This enables reduced space requirements, weight and resource optimization, as well as increased productivity and precision.

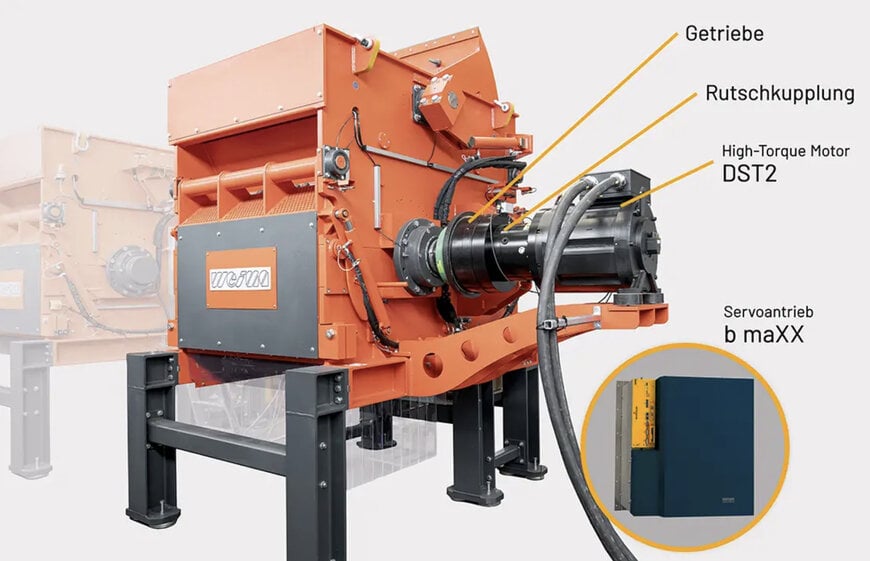

Plastics recycling – single-shaft shredder with electric high-torque drive

High peak and continuous torque. Special motor design. Perfectly matched drive train. These are just three of the requirements for shredder drives, which manufacturers like WEIMA Maschinenbau GmbH must meet. A fully electric system solution with a high-torque drive delivers all these advantages. Thanks to the Baumüller drive system with high-torque motor, high torque can be achieved even at low rotational speeds. With a precisely matched connection between the drive and rotor shaft, optimal power transmission is achieved, resulting in greater drive performance. This innovative drive system not only enables more economical operation but also supports more sustainable production.

At the K trade show, WEIMA will present a W5 series shredder in Hall 9, Booth A39, featuring a PowRex drive system from Baumüller and a Tevox® direct drive from Nidec Desch. The powerful PowRex drive system from Baumüller, consisting of a DST2 high-torque motor and a b maXX 5500 servo-controller, together with the rugged Tevox® direct drive with gearbox and coupling from Nidec Desch, now complement WEIMA’s drive portfolio as an innovative high-torque drive system.

Innovative high-torque drive system: The PowRex drive system from Baumüller will be shown LIVE at K 2025 together with a Tevox® direct drive from Nidec Desch on a W5.22 shredder from WEIMA.

Engineering Services

The Baumüller Group covers the entire spectrum of electrical drive technology. In addition to the technical innovations, visitors to the trade fair can also obtain advice on the wide range of services on offer. The specialist supports new projects from drive design to commissioning, contributing process expertise in almost all sectors of mechanical engineering. Years of experience also make Baumüller the ideal partner for optimizations, retrofits, and the implementation of individual development projects. With the subsidiary Baumüller Services, the after-sales service with repair and spare parts service is also available worldwide.

www.baumueller.com