www.ptreview.co.uk

11

'23

Written on Modified on

BAUMÜLLER PRESENTS PRECISE AND MODULAR DRIVE SOLUTIONS FOR THE TEXTILE INDUSTRY AT ITMA

At ITMA from June 8 to 14, 2023, the topics of Advanced Materials, Automation & Digital Future, Innovative Technologies, and Sustainability & Circularity will be in the spotlight.

The circular economy meets energy efficiency: Baumüller has applied itself to this topic for many years. Above all, direct drive technology leads to significantly lower energy costs. Baumüller has also developed the smart energy monitoring software tool for optimizing processes in, among other things, textile machines and presenting the energy costs transparently.

b maXX 6300 module system

The integrated control mode enables the detection of vibrations in machines with a challenging design, to analyze them in real time and to automatically optimize the process immediately. This measure increases the quality of the end product.

Boost your Performance. Reduce your Footprint:

Alongside the current b maXX 5000 series, Baumüller will be showing the most important innovation in its product portfolio, the future servo-controller generation, the b maXX 6000. This offers even better scalability as well as additional safety features, and smart Industry 4.0 functions, such as the energy monitoring integrated in the drive. Maximum control quality and dynamics as well as high power density are required in textile machines – the ideal area of use for the space-saving b maXX 6300 module system. The new controllers are faster and more reliable than ever before. Despite the expanded functional scope, the firmware is fully compatible with the preceding b maXX 5300 family – a changeover is therefore possible without new programming or parameterization.

Drive-based software solution for monitoring mechanics:

Condition monitoring solutions allow operators to keep track of the condition of many machines on a regular basis. The advantage: Early detection of motor wear avoids machine downtime. If sensors are used, this solution quickly becomes very expensive, especially in textile machines.

Baumüller has developed a software solution called Drive-Based Condition Monitoring, which enables condition monitoring without sensors. Since the software is integrated directly in the servo-controller, it can be easily retrofitted. The new function uses previously recorded and analyzed process parameters from the current and speed signal as reference values for monitoring the mechanics, such as the motor, fan and hydraulic pump. The FFT analysis detects changes in the vibration spectrum. These vibrations are caused, for example, by imbalance or faulty alignment.

If a significant deviation from the reference value is detected during operation, the software outputs an error signal. This allows planned maintenance to be carried out on the motor, preventing damage and accordingly machine failure. The comparison measurements are possible at fixed intervals or on demand, depending on the customer’s requirements. Monitoring is based on adjustable warning and error thresholds. Textile machine manufacturers can use the measurements for new business models in the area of data-driven additional services.

With the software solution Drive-Based Condition Monitoring, condition monitoring works without sensors. Since the software is integrated directly in the servo-controller, it can be easily retrofitted

Water-cooled servo motors:

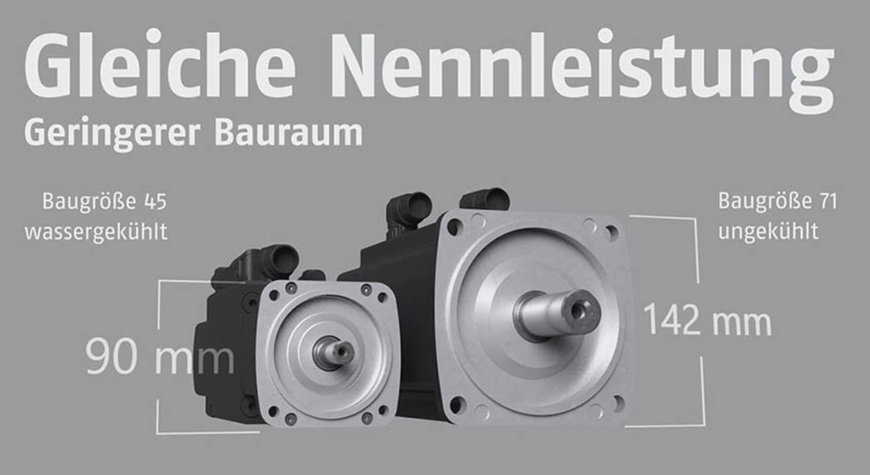

Water-cooled motors have many advantages: The active cooling increases the power density. In addition, close installation of multiple servo motors is easily possible due to the good heat dissipation. This saves space in the machine and the many axes is a positive aspect, particularly for textile machines. Baumüller also offers all sizes of its servo motors with water cooling.

With the Baumüller DSD2 servo motors, the output of a water-cooled servo motor in the size 45 is equivalent to that of an uncooled motor of size 71

Life-cycle management worldwide

In addition to the development and manufacture of automation components, as a group of companies, Baumüller provides numerous services for plant and machinery manufacturing and for machine operators. From project planning, design and engineering through assembly and commissioning to maintenance, retrofitting and relocation, Baumüller offers support over the entire life cycle of machines and systems. With over 40 branches worldwide, Baumüller is a reliable service partner with decades of experience. Baumüller attaches particular importance to the sustainable and resource-saving production of intelligent drive and automation solutions.

www.baumueller.com