www.ptreview.co.uk

17

'25

Written on Modified on

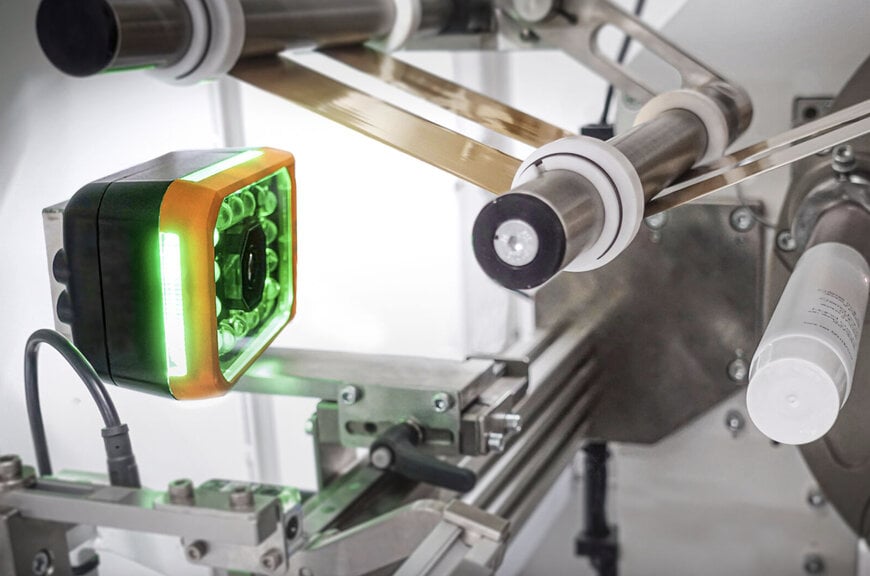

B&R launches AI-enabled Smart Camera for real-time vision in the control loop

B&R’s new Smart Camera brings AI directly into the machine control loop—enabling real-time vision, dynamic model switching, and up to 15× higher processing efficiency at the edge.

www.br-automation.com

B&R has introduced a next-generation Smart Camera that brings advanced artificial intelligence directly into the machine control loop. With integrated edge AI capabilities, the new camera enables real-time vision processing, dynamic model switching, and hybrid AI-rule-based inspection—all without halting production or requiring external hardware.

This launch marks a significant step forward in intelligent automation, offering machine builders and manufacturers a compact, plug-and-play solution that delivers higher quality, faster throughput, and reduced waste—even under highly variable production conditions.

AI vision that adapts in real time

“What sets our new Smart Camera apart is the ability to embed it in the control loop which enables tuning machines on the fly,” said Florian Schneeberger, Chief Technology Officer, ABB Machine Automation (B&R). “It’s no longer just about seeing defects; it’s about reacting to them instantly.”

Another key advantage of the Smart Camera is its flexibility. “Customers can switch models and combine AI functions in custom sequences—without interrupting production,” Schneeberger added. This capability allows manufacturers to quickly adapt to new product variants or defect types, and to integrate AI incrementally alongside existing rule-based systems.

Unlike conventional systems that depend on external PCs or PLCs, B&R’s solution processes image data locally, enabling real-time AI inference at the edge—powered by an edge AI processor with up to 15× higher efficiency than comparable processors, according to performance benchmarks from Hailo.

Hybrid intelligence for maximum flexibility

The Smart Camera supports a full suite of AI-based vision functions from MVTec—including optical character recognition (OCR), anomaly detection, object detection, classification, and semantic segmentation. These can be combined with traditional rule-based algorithms in a hybrid workflow, enabling users to balance the flexibility of AI with the speed and precision of conventional vision.

This hybrid approach is ideal for complex inspection tasks such as identifying product types, detecting subtle defects, and verifying printed codes—all in a single pass and with a single device.

Fast deployment, scalable integration

Designed for rapid deployment, the Smart Camera integrates seamlessly into B&R’s Automation Studio engineering environment. A low-code interface allows automation engineers to configure AI vision tasks, simulate results, and manage models without specialist expertise. Existing Smart Camera installations can be upgraded with a simple drop-in replacement.

“Automation engineers can deploy AI vision in hours, not days,” said Schneeberger. “And because the system is fully synchronized with machine control, it boosts overall equipment effectiveness without adding complexity.”

Optimized imaging for better AI results

B&R’s factory-calibrated optics and lighting improve imaging repeatability by a factor of 10 or more, ensuring high-quality input for deep learning models. This results in more accurate detection, fewer false positives, and better long-term performance.

From food and pharma to cosmetics, textiles, and automotive, the Smart Camera is built to handle unpredictable variations in materials, lighting, and positioning. Its ability to perform multiple inspection tasks in one pass reduces hardware requirements and shortens cycle times—delivering measurable gains in productivity and quality.

To learn more about B&R’s AI vision systems and explore the new Smart Camera, visit the B&R website under vision systems.

www.br-automation.com