www.ptreview.co.uk

12

'25

Written on Modified on

HEIDENHAIN debuts rotary encoders with vibration analysis

At Automatica 2025, HEIDENHAIN & its brands showcase rotary & dual encoders with vibration analysis, collision monitoring, & precise motor feedback for robotics.

www.heidenhain.com

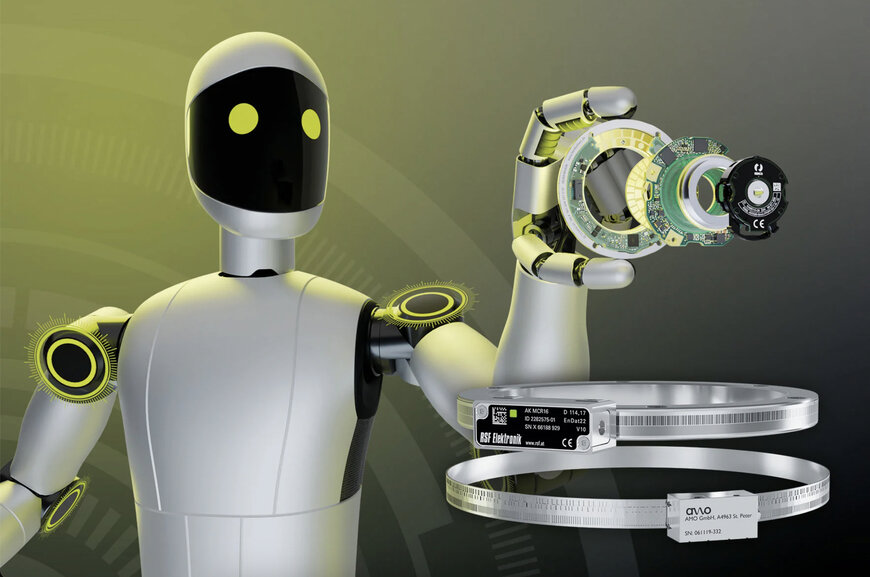

Optimal rotary encoders for every application: The product range for robotics and automation at HEIDENHAIN and its brands AMO, RSF and RENCO offers intelligent solutions for the full spectrum of applications.

Fully intercompatible: The ECI and EQI rotary encoder platform

Thanks to their modular design, the ECI and EQI inductive rotary encoders from HEIDENHAIN give drive-system manufacturers numerous options for adapting motor feedback to their specific applications without needing to change the electronic or mechanical interfaces of their systems. The mechanical mounting interfaces of these rotary encoders are fully intercompatible within each series: the 1100 series with a 35 mm diameter and the 1300 series with a 56 mm diameter. These encoders are also mechanically compatible with many other identically sized rotary encoders within the HEIDENHAIN product range, including the ECN/EQN 1300 optical rotary encoder series. Meanwhile, the digital EnDat 3 data interface enables functionally safe applications up to SIL 3 without additional measures.

Improved accuracy and safety for cobots:

Dual and secondary encoders for collision monitoring

Delivering positioning feedback both upstream and downstream from a robot joint’s gear systems increases robot accuracy. This can be achieved with HEIDENHAIN dual encoders or with conventional motor encoders combined with AMO or RSF secondary encoders. But greater robot accuracy is not the only benefit. This arrangement can also detect the effects of forces acting on the gear systems of individual robot joints, including collisions. Cobot manufacturers can therefore use this added capability to implement targeted collision monitoring without the need for additional torque sensors. A demonstration unit consisting of a cobot with these types of HEIDENHAIN rotary encoders will demonstrate force measurement and how it enables adherence to safety limits.

Versatile platform: Featuring the EnDat 3 data interface and two different mechanical interfaces, the ECI and EQI inductive rotary encoders from HEIDENHAIN deliver optimal motor feedback for automated applications at every performance level.

Simplified mounting with no extra sensors through built-in vibration analysis:

The ECI 1323 Splus and EQI 1335 Splusinductive rotary encoders from HEIDENHAIN

Early detection of machine vibration is vital for ensuring smooth processes, perfect results and machine longevity in high-performance and capital-intensive automation systems. As a result, users can minimize scrap, prevent machine damage and reduce system downtime. The ECI 1323 Splus and EQI 1335 Splus inductive rotary encoders from HEIDENHAIN, featuring a built-in accelerometer and integrated vibration analysis, are a particularly convenient solution for detecting and analyzing vibrations in machine elements. These encoders unite position feedback and vibration analysis—and thus motion control and collision monitoring—within a single device. The link they establish between vibration and position signals also makes it easier to identify the type and location of a vibration’s source. An external temperature sensor can be connected to these encoders as well.

The ECI 1323 Splus and EQI 1335 Splus thus enable targeted online condition monitoring that allows machine faults to be detected and analyzed at an early stage. Based on this condition monitoring data, machine operators can implement predictive maintenance to optimize their machine servicing intervals in accordance with wear levels as well as adapt their production schedules based on immanent breakdowns.

All the data from the ECI 1323 Splus and EQI 1335 Splus encoders is transmitted to the downstream electronics via the EnDat 3 interface, thereby eliminating the need for separate vibration sensors and significantly reducing cabling and installation complexity.

Higher accuracy and collision monitoring without additional torque sensors: A demo unit at the HEIDENHAIN booth will be showcasing the benefits of dual encoders and secondary encoders for cobots.

Modular angle encoders from AMO and RSF:

Secondary encoders for robot motors with wide shaft diameters

Robot manufacturers can significantly improve the absolute position accuracy of their robots by adding a high-accuracy angle encoder on robot axes. Installed downstream from the gear system, secondary encoders determine the actual position of every robot joint, thereby enabling numerous new robot applications. Modular solutions, such as the WMRA angle encoder from AMO or the new MCR 16 angle encoder from RSF, are strong contenders in this field. Thanks to their modular design with a scale drum or measuring ring and a separate scanning unit, they are ideal for large shaft diameters and tight installation spaces. The inductive secondary encoder solutions from AMO feature high robustness and a versatile mechanical design. The MCR 16 from RSF delivers optical scanning with improved signal quality for absolute position measurement on large-diameter axes.

HEIDENHAIN will be at AUTOMATICA from June 24–26, 2025 at Hall B6, Booth 302.

www.heidenhain.com

Fully intercompatible: The ECI and EQI rotary encoder platform

Thanks to their modular design, the ECI and EQI inductive rotary encoders from HEIDENHAIN give drive-system manufacturers numerous options for adapting motor feedback to their specific applications without needing to change the electronic or mechanical interfaces of their systems. The mechanical mounting interfaces of these rotary encoders are fully intercompatible within each series: the 1100 series with a 35 mm diameter and the 1300 series with a 56 mm diameter. These encoders are also mechanically compatible with many other identically sized rotary encoders within the HEIDENHAIN product range, including the ECN/EQN 1300 optical rotary encoder series. Meanwhile, the digital EnDat 3 data interface enables functionally safe applications up to SIL 3 without additional measures.

Improved accuracy and safety for cobots:

Dual and secondary encoders for collision monitoring

Delivering positioning feedback both upstream and downstream from a robot joint’s gear systems increases robot accuracy. This can be achieved with HEIDENHAIN dual encoders or with conventional motor encoders combined with AMO or RSF secondary encoders. But greater robot accuracy is not the only benefit. This arrangement can also detect the effects of forces acting on the gear systems of individual robot joints, including collisions. Cobot manufacturers can therefore use this added capability to implement targeted collision monitoring without the need for additional torque sensors. A demonstration unit consisting of a cobot with these types of HEIDENHAIN rotary encoders will demonstrate force measurement and how it enables adherence to safety limits.

Versatile platform: Featuring the EnDat 3 data interface and two different mechanical interfaces, the ECI and EQI inductive rotary encoders from HEIDENHAIN deliver optimal motor feedback for automated applications at every performance level.

Simplified mounting with no extra sensors through built-in vibration analysis:

The ECI 1323 Splus and EQI 1335 Splusinductive rotary encoders from HEIDENHAIN

Early detection of machine vibration is vital for ensuring smooth processes, perfect results and machine longevity in high-performance and capital-intensive automation systems. As a result, users can minimize scrap, prevent machine damage and reduce system downtime. The ECI 1323 Splus and EQI 1335 Splus inductive rotary encoders from HEIDENHAIN, featuring a built-in accelerometer and integrated vibration analysis, are a particularly convenient solution for detecting and analyzing vibrations in machine elements. These encoders unite position feedback and vibration analysis—and thus motion control and collision monitoring—within a single device. The link they establish between vibration and position signals also makes it easier to identify the type and location of a vibration’s source. An external temperature sensor can be connected to these encoders as well.

The ECI 1323 Splus and EQI 1335 Splus thus enable targeted online condition monitoring that allows machine faults to be detected and analyzed at an early stage. Based on this condition monitoring data, machine operators can implement predictive maintenance to optimize their machine servicing intervals in accordance with wear levels as well as adapt their production schedules based on immanent breakdowns.

All the data from the ECI 1323 Splus and EQI 1335 Splus encoders is transmitted to the downstream electronics via the EnDat 3 interface, thereby eliminating the need for separate vibration sensors and significantly reducing cabling and installation complexity.

Higher accuracy and collision monitoring without additional torque sensors: A demo unit at the HEIDENHAIN booth will be showcasing the benefits of dual encoders and secondary encoders for cobots.

Modular angle encoders from AMO and RSF:

Secondary encoders for robot motors with wide shaft diameters

Robot manufacturers can significantly improve the absolute position accuracy of their robots by adding a high-accuracy angle encoder on robot axes. Installed downstream from the gear system, secondary encoders determine the actual position of every robot joint, thereby enabling numerous new robot applications. Modular solutions, such as the WMRA angle encoder from AMO or the new MCR 16 angle encoder from RSF, are strong contenders in this field. Thanks to their modular design with a scale drum or measuring ring and a separate scanning unit, they are ideal for large shaft diameters and tight installation spaces. The inductive secondary encoder solutions from AMO feature high robustness and a versatile mechanical design. The MCR 16 from RSF delivers optical scanning with improved signal quality for absolute position measurement on large-diameter axes.

HEIDENHAIN will be at AUTOMATICA from June 24–26, 2025 at Hall B6, Booth 302.

www.heidenhain.com