www.ptreview.co.uk

14

'25

Written on Modified on

ABB News

Australian tech innovator Vision AI becomes an ABB Robotics Authorized Value Provider

Vision AI joins ABB Robotics Australia as an AVP, using advanced automation and robotics to address labor shortages and optimize agricultural operations.

global.abb

Peter Bradbury, Channel Manager for ABB Robotics in Australia presents the ABB Authorized Value Provider plaque to Mark Strangio-McRae, Founder and Director of Vision AI.

Vision AI is an innovative local Australian company that specialises in advanced automation using robotics and machine vision. They have just become ABB Robotics Australia's newest Authorized Value Provider (AVP), joining a prestigious network of businesses committed to promoting progress in robotic automation to propel knowledge of the benefits of robot applications around the world.

An ABB Channel Partner since 2022, Vision AI has already made great strides in locally designing, engineering, and manufacturing tailored solutions to modernise and optimise industrial processes for their customers in the agriculture and food sectors.

They are leading experts in integrating vision systems with robotic platforms to support customers in improving their grading, selecting, and packaging applications using integrated machine vision systems with robotic technology. This powerful combination enables precise control and handling, higher productivity levels, and final product reliability in manufacturing and production environments.

As an ABB Robotics AVP, Vision AI will benefit from expert support for design obstacles via both local and global specialists. They will also have the opportunity to participate in complementary robotic training courses focused on optimally growing the skills of robot technicians.

Additionally, Vision AI will have access to ABB’s RobotStudio®, an offline programming and simulation tool offering users advanced robot programming and optimisation exploration pathways for testing, validation, visualisation, and optimisation.

This comprehensive support ensures AVPs are equipped with the resources to drive success in their projects and operations and deliver faster implementation of solutions for their customers.

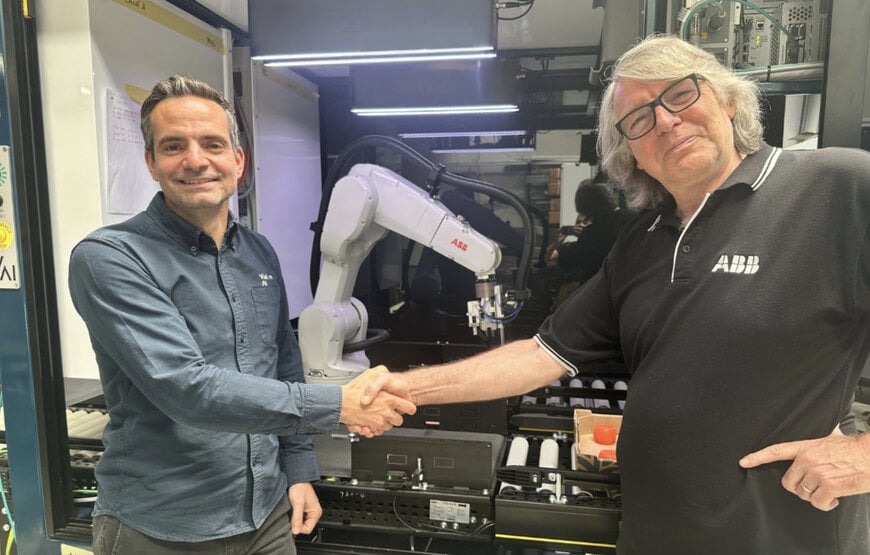

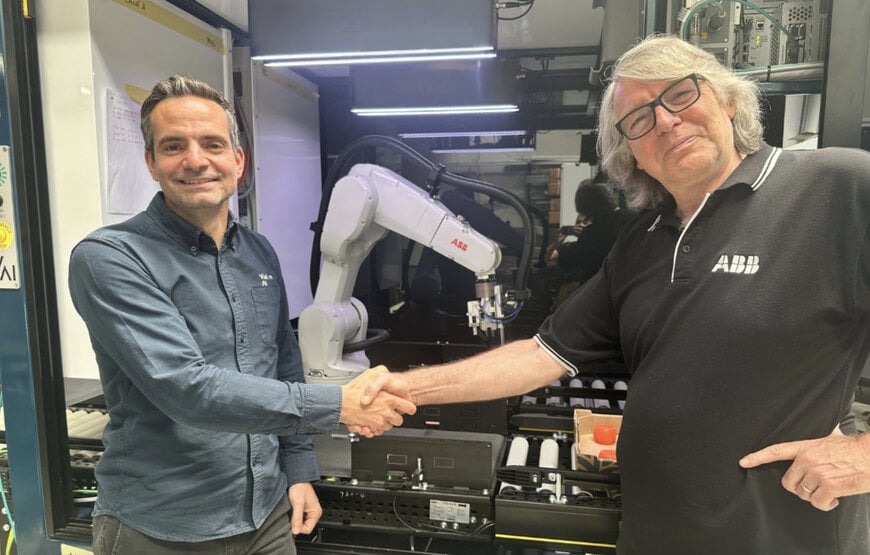

Mark Strangio-McRae, Founder and Director of Vision AI (left), presents their innovative intelligent fruit grading and packing machine, powered by ABB robotics, to Peter Bradbury, Channel Manager for ABB Robotics in Australia (right).

"From the start, I set out to redefine what’s possible for Australian industries," said Mark Strangio-McRae, Founder and Director of Vision AI. Shared his inspiring vision, he continues, “From the start, I set out to redefine what’s possible for Australian industries. We wanted to be a supplier of next-gen solutions that were never seen before. I could see critical gaps that needed to be filled in the market, and where robotic automation could support in solving those problems to reshape the future of these industries.”

They have already designed and assembled a precision-driven intelligent fruit grading and packing solution that uses ABB’s IRB 1200 and IRB 1300 industrial robots in a world-first application that will be supplied to Victorian glasshouse fruit and vegetable grower Flavorite to accelerate and optimise their operations. The system exemplifies the cutting-edge advancements in machine vision and artificial intelligence that are pushing the boundaries of what's possible in manufacturing automation.

The solution leverages advanced vision software to grade and select fruit on a production line, using techniques including edge detection, contour analysis, and colour recognition. It is helping to outmanoeuvre ongoing labour shortage issues in Australia's agricultural sector, including workers required for fruit harvesting. This automation of the grading process is not just enhancing efficiency and increasing productivity by accelerating the packaging process, but it's also helping to support the sustainable growth of the industry while answering consumer demand for greater product availability.

Up to thirteen of ABB’s industrial robots are integrated into the 50-meter-long production line of this platform, handling both the packing application and the cutting of fruits and vegetables. For example, they trim low-value truss tomatoes, turning what would otherwise be classified as waste into valuable byproducts, such as ingredients for canned vegetables and other consumer goods. This efficient process maximises the use of available resources with sustainable practices.

Vision AI’s Dynamic Box Detection system is a self-managed solution featuring ABB robots and 2D/3D camera technologies used for complex pallet stacking and de-stacking.

Vision AI's system is also equipping businesses with the freedom to decrease the number of employees required for such tasks from twenty to as little as two, giving staff the opportunity to sidestep repetitive or redundant work and instead focus on growing their skills in other areas. This can increase the value of these employees to their employers, resulting in happier teams and increased productivity.

When asked why he continues to choose ABB robots Mark said, “ABB technology and software stands out for its user-friendliness and ease of adoption. This is especially crucial when training graduates, as they can grasp the software quickly. Beyond that, I truly value the local ABB Robotics team in Australia. Their expertise and unwavering support make this partnership an ongoing success.”

At Vision AI, their goal is to also positively change both corporate culture and employee development in the engineering field. "Engineering can be a tough industry, often traditional in its approach to workforce development. But here at Vision AI, we're committed to doing better. We support our employees by offering them opportunities to learn new skills - whether through AI, deep learning, or flexible work practices, that will help them thrive in their careers," said Mark.

The company remains dedicated to reshaping the way employees are trained and upskilled, focusing on equipping them with the tools, knowledge, and access to industry partnerships they need to excel in the rapidly evolving technology landscape.

Peter Bradbury, Channel Manager for ABB Robotics in Australia said, “Vision AI is undoubtedly one of the most exciting tech and robotic automation companies in Australia’s agriculture and food sectors. I’m eager to see where their innovation journey takes them next, especially with their ambitious plans to expand into other industries. No doubt their groundbreaking technology will soon be featured in even more businesses, both in Australia and abroad.”

www.abb.com

Vision AI is an innovative local Australian company that specialises in advanced automation using robotics and machine vision. They have just become ABB Robotics Australia's newest Authorized Value Provider (AVP), joining a prestigious network of businesses committed to promoting progress in robotic automation to propel knowledge of the benefits of robot applications around the world.

An ABB Channel Partner since 2022, Vision AI has already made great strides in locally designing, engineering, and manufacturing tailored solutions to modernise and optimise industrial processes for their customers in the agriculture and food sectors.

They are leading experts in integrating vision systems with robotic platforms to support customers in improving their grading, selecting, and packaging applications using integrated machine vision systems with robotic technology. This powerful combination enables precise control and handling, higher productivity levels, and final product reliability in manufacturing and production environments.

As an ABB Robotics AVP, Vision AI will benefit from expert support for design obstacles via both local and global specialists. They will also have the opportunity to participate in complementary robotic training courses focused on optimally growing the skills of robot technicians.

Additionally, Vision AI will have access to ABB’s RobotStudio®, an offline programming and simulation tool offering users advanced robot programming and optimisation exploration pathways for testing, validation, visualisation, and optimisation.

This comprehensive support ensures AVPs are equipped with the resources to drive success in their projects and operations and deliver faster implementation of solutions for their customers.

Mark Strangio-McRae, Founder and Director of Vision AI (left), presents their innovative intelligent fruit grading and packing machine, powered by ABB robotics, to Peter Bradbury, Channel Manager for ABB Robotics in Australia (right).

"From the start, I set out to redefine what’s possible for Australian industries," said Mark Strangio-McRae, Founder and Director of Vision AI. Shared his inspiring vision, he continues, “From the start, I set out to redefine what’s possible for Australian industries. We wanted to be a supplier of next-gen solutions that were never seen before. I could see critical gaps that needed to be filled in the market, and where robotic automation could support in solving those problems to reshape the future of these industries.”

They have already designed and assembled a precision-driven intelligent fruit grading and packing solution that uses ABB’s IRB 1200 and IRB 1300 industrial robots in a world-first application that will be supplied to Victorian glasshouse fruit and vegetable grower Flavorite to accelerate and optimise their operations. The system exemplifies the cutting-edge advancements in machine vision and artificial intelligence that are pushing the boundaries of what's possible in manufacturing automation.

The solution leverages advanced vision software to grade and select fruit on a production line, using techniques including edge detection, contour analysis, and colour recognition. It is helping to outmanoeuvre ongoing labour shortage issues in Australia's agricultural sector, including workers required for fruit harvesting. This automation of the grading process is not just enhancing efficiency and increasing productivity by accelerating the packaging process, but it's also helping to support the sustainable growth of the industry while answering consumer demand for greater product availability.

Up to thirteen of ABB’s industrial robots are integrated into the 50-meter-long production line of this platform, handling both the packing application and the cutting of fruits and vegetables. For example, they trim low-value truss tomatoes, turning what would otherwise be classified as waste into valuable byproducts, such as ingredients for canned vegetables and other consumer goods. This efficient process maximises the use of available resources with sustainable practices.

Vision AI’s Dynamic Box Detection system is a self-managed solution featuring ABB robots and 2D/3D camera technologies used for complex pallet stacking and de-stacking.

Vision AI's system is also equipping businesses with the freedom to decrease the number of employees required for such tasks from twenty to as little as two, giving staff the opportunity to sidestep repetitive or redundant work and instead focus on growing their skills in other areas. This can increase the value of these employees to their employers, resulting in happier teams and increased productivity.

When asked why he continues to choose ABB robots Mark said, “ABB technology and software stands out for its user-friendliness and ease of adoption. This is especially crucial when training graduates, as they can grasp the software quickly. Beyond that, I truly value the local ABB Robotics team in Australia. Their expertise and unwavering support make this partnership an ongoing success.”

At Vision AI, their goal is to also positively change both corporate culture and employee development in the engineering field. "Engineering can be a tough industry, often traditional in its approach to workforce development. But here at Vision AI, we're committed to doing better. We support our employees by offering them opportunities to learn new skills - whether through AI, deep learning, or flexible work practices, that will help them thrive in their careers," said Mark.

The company remains dedicated to reshaping the way employees are trained and upskilled, focusing on equipping them with the tools, knowledge, and access to industry partnerships they need to excel in the rapidly evolving technology landscape.

Peter Bradbury, Channel Manager for ABB Robotics in Australia said, “Vision AI is undoubtedly one of the most exciting tech and robotic automation companies in Australia’s agriculture and food sectors. I’m eager to see where their innovation journey takes them next, especially with their ambitious plans to expand into other industries. No doubt their groundbreaking technology will soon be featured in even more businesses, both in Australia and abroad.”

www.abb.com