www.ptreview.co.uk

14

'24

Written on Modified on

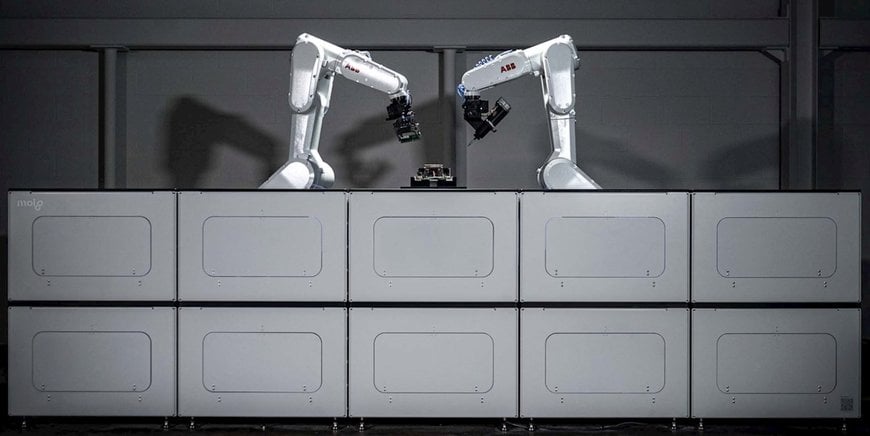

ABB Robotics and Molg tackle data center e-waste with robotic microfactories

With e-waste projected to rise to 75 million tons by 2030, the automated disassembly and recovery of disused electronic equipment addresses environmental and regulatory demands, including worker welfare.

global.abb

ABB Robotics is collaborating with US start-up Molg to create robotic microfactories to recover and recycle data center operators’ disused electronic equipment, commonly known as e-waste. With global e-waste projected to rise to 75 million tons by 2030, the microfactories will play a vital role in reducing the electronic waste, helping the data center sector operate more efficiently and sustainably.

Advances in computing such as AI, machine learning and the cloud necessitate the need for data centers to upgrade and expand their facilities more frequently. Today, data centers are major contributors to the 2.6 million tonnes of e-waste generated worldwide each year.

ABB Robotics continues to support innovation ecosystems through collaboration and venture capital investments. ABB Robotics & Automation Ventures (ABB RA Ventures) participated with an investment in Molg’s seed round led by Closed Loop Partners’ Ventures Group, alongside Amazon’s Climate Pledge Fund, Overture, Elemental Impact and Techstars Ventures.

Molg was recognized as a winner by ABB’s Motion drive business in its ABB Accelerating Circularity Startup Challenge 2023, Molg’s robotic microfactory can autonomously assemble and disassemble complex electronic products including laptop PCs, servers, and industrial electronics.

As an alternative to manual disassembly, or sending equipment to landfill or incineration, the microfactory solves many of the challenges associated with the disposal of electronic waste. With end users facing increasing regulations regarding the responsible handling of de-commissioned equipment, automated disassembly reduces the risks associated with handling toxic elements that can damage the environment and human health, and releases workers from handling arduous and potentially dangerous tasks.

With many components also containing rare earth elements (REEs), the ability to maximize their recovery through automation also provides an economic opportunity to reuse them in the production of new electronic equipment.

The microfactory solution is aimed at hyperscalers operating large networks of data centers and IT Asset Disposition (ITAD) companies.

The solution is part of Molg’s wider portfolio that includes design-for-circularity and component traceability software tools enabling manufacturers to create products that can be easily de-manufactured and recycled at the end of their life.

www.abb.com