www.ptreview.co.uk

01

'24

Written on Modified on

IMA Schelling Launches AMD.work and HP.stack for Next-Level Aluminium Processing Automation

The new AMD.work and HP.stack solutions streamline heavy plate handling and cutting, enhancing precision and efficiency while reducing dependency on skilled labour.

www.imaschelling.com

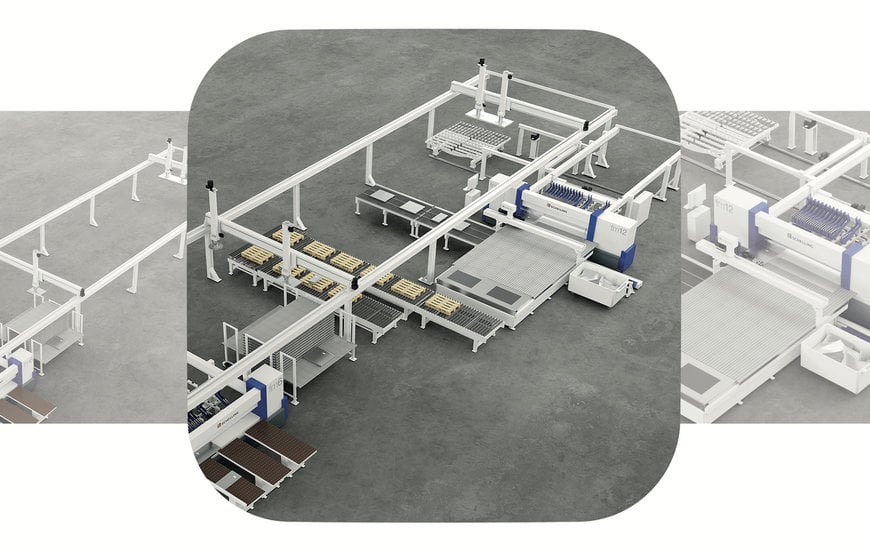

IMA Schelling Precision is responding to the increasing demands being placed on aluminium processing by launching a pair of new automation solutions: the AMD.work and HP.stack. These smart handling systems allow customers to streamline their cut-to-size operations for heavy aluminium plates and reduce their dependence on skilled labour while increasing the quality and precision of their products.

The innovative systems from IMA Schelling Precision can be flexibly adapted to each customer's unique circumstances and can be expanded as required. AMD.work is the first step towards fully automated production. Specially designed for use on the saw, this unit is capable of taking over all the handling work for the operator. It does so by removing the cut strips from the cutting line, accurately depositing them and then reinserting them for the transverse cut. In the final step, the system discharges the finished strips via a conveyor line. The handling unit can be combined with the fm8, fm10 and fm12 cut-to-size saws from IMA Schelling Precision.

Flexible and versatile – the HP.stack handling gantry

The HP.stack solution from IMA Schelling Precision kicks off the second stage of automation. The handling gantry can be located next to the saw, where it takes over a wide range of tasks. In addition to feeding the saw with aluminium plates directly from a cassette, HP.stack can also pick up the finished blanks from a roller track or conveyor and deposit them on a different conveyor line, in boxes or on pallets. And the best part is that the system can be placed directly next to the discharge aisle at a warehouse.

The gantry can accommodate several suction tools in order to handle both large plates weighing up to 3,000 kg as well as the smallest blanks measuring just 50 x 50 mm. The system is even able to return remainder plates back to the warehouse. Like AMD.work, HP.stack can be used in combination with the fm8, fm10 and fm12 saws from IMA Schelling Precision.

IMA Schelling – the perfect solution for every idea

The IMA Schelling Group develops, designs and manufactures machinery and plants for woodworking, plastics and metalworking companies. Its customers include international furniture manufacturers, aircraft manufacturers and family-run carpentry businesses with exacting requirements. The company draws on over 100 years' experience when developing its innovative processing solutions for the most advanced networked production lines, tailored to individual customer needs – right through to fully automated batch size 1 systems.

The intelligent high-end solutions are designed by employees in four business units: Board, Woodworking, Precision and Consulting. Customers can count on an extensive level of expertise across many areas, such as cutting, drilling, edge processing and material logistics solutions in the woodworking sector, or cutting and handling solutions for metals, plastics and construction materials. Custom strategies to achieve business development based on added value as well as consulting, software and digitalisation products complete the portfolio.

www.imaschelling.com