www.ptreview.co.uk

30

'24

Written on Modified on

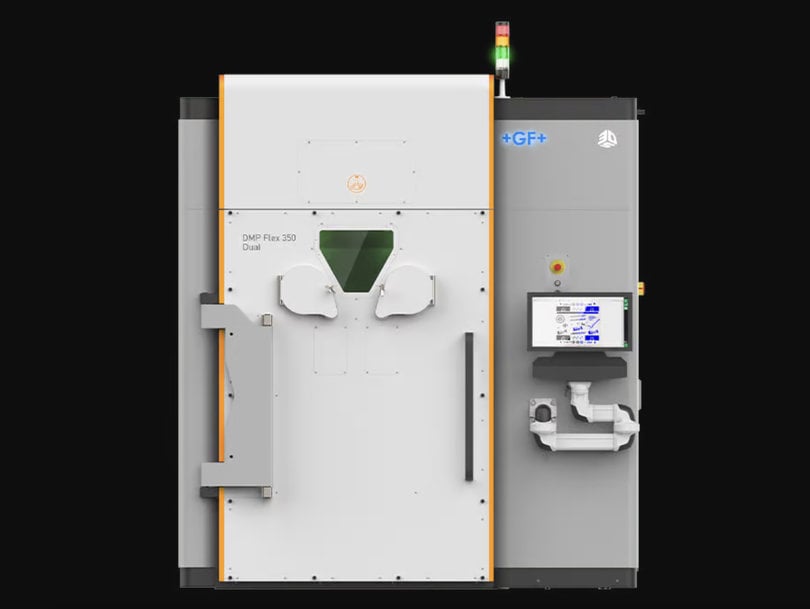

WEAREAM ADDS 3D SYSTEMS DMP FLEX 350 DUAL TO MANUFACTURING WORKFLOW

DMP Flex 350 Dual delivers speed, flexibility to enable increased options for WeAreAM and Gruppo Grazioli customers.

3D Systems announced that WeAreAM, a digital and metal additive manufacturing company located in Brescia, Lombardia, Italy, has added 3D Systems’ DMP Flex 350 Dual to its new Center of Excellence. The addition of 3D Systems’ direct metal printing solution will enable WeAreAM to explore an expanded set of applications — allowing the company to become increasingly responsive to its customers’ requirements, thus helping accelerate innovation.

3D Systems’ newest partner in Italy, Gruppo Grazioli, will work in close collaboration with WeAreAM providing training, support, and other services to ensure manufacturers integrating AM are maximizing the solution and thus their investment.

The DMP Flex 350 Dual enables flexible application use and quick-swap build modules, and a central server to manage print jobs, materials, settings, and maintenance for 24/7 productivity.

Additionally, the unique vacuum chamber significantly reduces argon gas consumption while delivering best-in-class oxygen purity (<25 ppm). The printer also includes Oqton’s 3DXpert software which supports every step of the additive manufacturing workflow from design to post-processing, to quickly and efficiently transition from a 3D model to successfully printed parts. This single software solution for modelling, simulation, and manufacturing eliminates the need to rely on multiple software packages. Efficiencies driven by 3DXpert can enable up to 75% faster file-processing time, and increase productivity by up to 40%.

www.3dsystems.com