www.ptreview.co.uk

07

'23

Written on Modified on

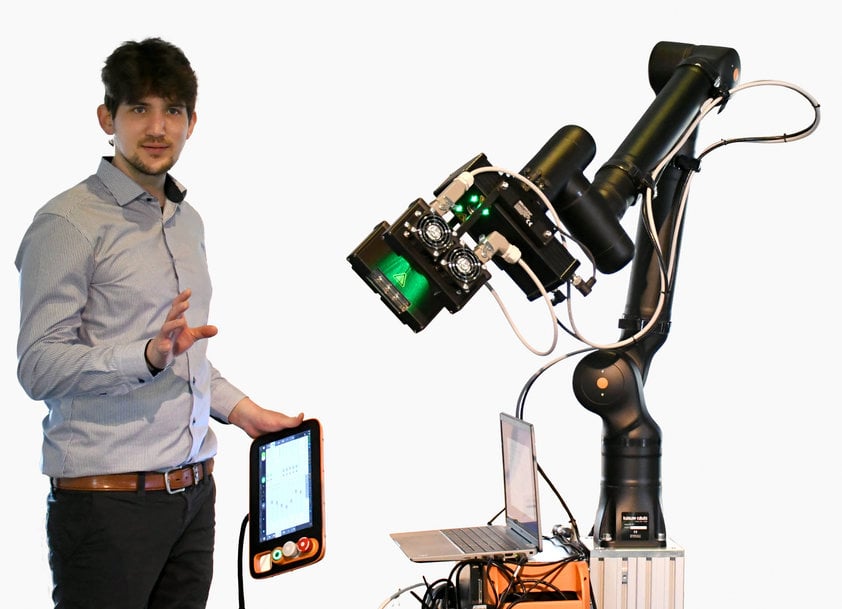

Perfect lightweight parts Inspection system from TENTA VISION reveals defects in real time

Its new inspection system which is based on a patented optical-interferometric measuring device uses components from Bosch Rexroth, Kassow Robots and PTS Group GmbH.

TENTA VISION GmbH would like to make it as easy as possible for customers to inspect materials and components. . The compact system reveals internal and external defects in lightweight parts – contactlessly and in real time.

The new inspection system comprises an excitation and control unit, a computer and intelligent automation software, and it can be deployed quickly. Possible applications range from vehicle construction and the aerospace industry to energy storage and many other sectors. The technology is used to inspect a wide range of lightweight materials and components.

A 7-axes lightweight robot from Kassow Robots moves the measuring device to the desired position – Bosch Rexroth had acquired a majority stake in the Danish company in 2022. PTS supplies the robust subframe made from Rexroth aluminum profiles which was designed to fit through doors 90 cm wide. PTS produced the connecting parts from high-quality Onyx filament material using a 3D printer. Onyx is a durable PA6 with micro-carbon fibers that is 1.4 times stiffer than ABS thermoplastics and offers high surface quality and heat tolerance.

The PTS Group is one of around 60 Bosch Rexroth Certified Excellence Partners. As local contacts, certified partner companies such as PTS provide customers with support in the form of readily available products, their own engineering services and/or comprehensive servicing.

www.boschrexroth.com