www.ptreview.co.uk

13

'23

Written on Modified on

Replique Launches Material Database at Formnext 2023 to Simplify Selection in Additive Manufacturing

Replique is enhancing the accessibility of collective material knowledge within the 3D printing community, facilitated by its trusted material partners, by launching a new material database at its booth in Hall 12.1, #A107.

Replique’s material database as a knowledge hub for users and service providers

The careful and informed selection of materials is crucial for the success of AM projects. So far however, this research process has been manual and labor-intensive. Replique's material database now provides users with an intuitive platform that empowers them to select the ideal materials for their specific applications.

This not only saves time and costs but also guarantees the quality of additive manufactured components in terms of material requirements. The database features various filtering options, including technical specifications, industry standards, and application fields. Additionally, it will offer quick access to reference cases and certificates in the future, eliminating the need for time-consuming inquiries. This data is the result of partnerships established with renowned material manufacturers in the past year.

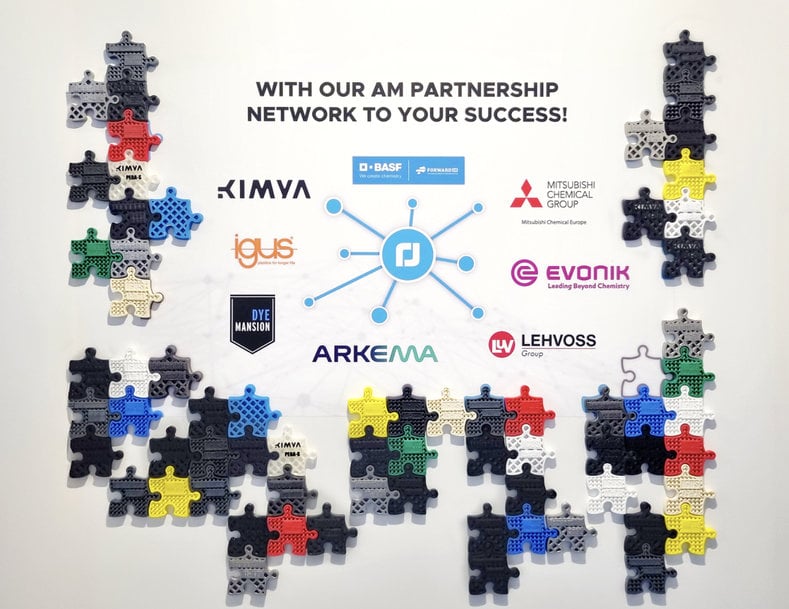

Replique's material partner network, showcased at last year's Formnext, builds a foundation of the material database, offering customers access to top-quality materials and knowhow.

Open design enables cross-platform usage of the database

It's not just end-users who benefit from the material database. Printer manufacturers, service providers, and other interested companies can also leverage and contribute to the database, enriching their work and services with material insights. The advantage lies in the database's design as an open system. As a result, the material data will be accessible not only through the Replique platform directly but also through an API interface in the near future. All data will be available behind a free password barrier for the convenience of all interested parties.

The material database serves as another essential component of Replique's comprehensive ecosystem, which includes various services, such as Additive Marking who enable the traceability of 3D printed parts. This holistic approach ensures that Replique’s users can access all the necessary information and services conveniently within a single central interface – the Replique platform.

www.replique.com