www.ptreview.co.uk

12

'23

Written on Modified on

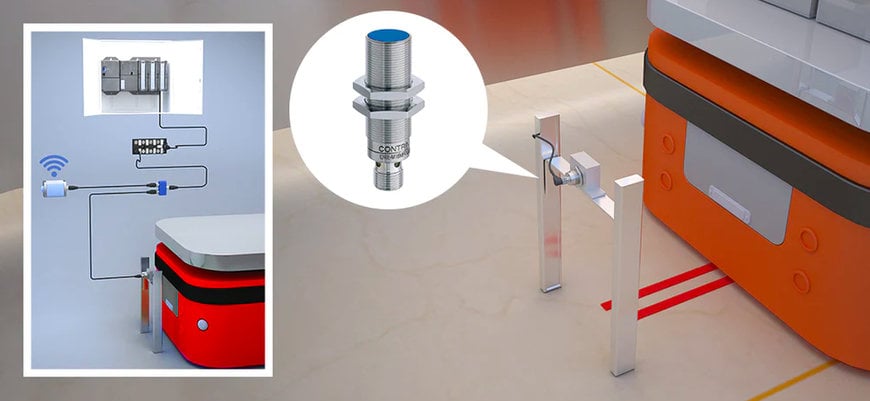

SMART INDUCTIVE BASIC SENSORS FOR AGV POSITIONING AND MACHINE OPTIMIZATION

Contrinex Smart Sensors, designed with the needs of smart factories in mind, have all the answers when it comes to reducing complexity and cost.

An inductive Basic Smart Sensor, positioned in the docking bay of a pick-and-place loading machine, senses the approach of an AGV and communicates via IO-Link with a central PLC, ensuring safe two-speed docking. Using its second output, the sensor also communicates with a local control system via a wireless hub, initiating start-up for the pick-and-place machine, which has been on standby since the completion of the previous loading cycle.

Local optimization of machine utilization and energy usage optimizes effectiveness

- Smart inductive sensor supports two-speed AGV docking to reduce cycle time

- Simple IO-Link routines trigger a low-speed final approach at a pre-set distance

- Secondary output communicates wirelessly with local control systems

- Machine standby is initiated and ended based on demand, reducing energy needs