www.ptreview.co.uk

18

'23

Written on Modified on

Brush lifting devices added to the standard portfolio Menzel

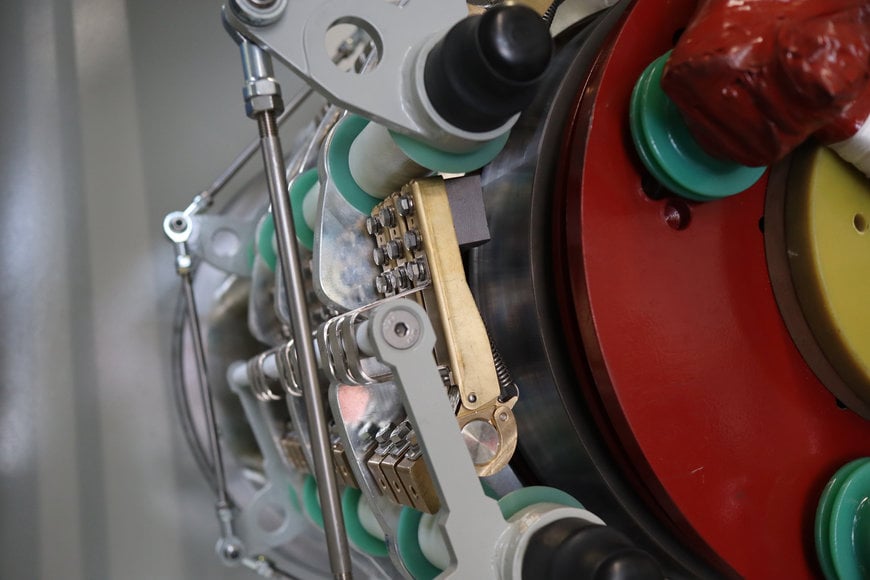

Menzel Elektromotoren can fit slip ring motors with short-circuiting and brush-lifting devices on request and has now added this option to its standard portfolio.

Motor brush lifting can be worthwhile for motors from about size 630 operating with long running times and infrequent restarts. It serves to significantly reduce maintenance requirements. Sample applications include pumps, fans and conveyors in continuous operation (duty type S1). After motor ramp-up, the rotor windings can be short-circuited and the carbon brushes lifted. This reduces brush wear.

Smaller brushes can be used, which often last the entire motor lifespan. This eliminates the cost and effort required for regular brush replacement. Also, the slip ring compartment needs to be cleaned much less frequently due to reduced amounts of carbon dust. The modular brush-lifting devices feature a top-quality, low-maintenance and extremely robust design. Specifically designed for each application, the slip-ring body, including the short-circuit ring, is dimensioned relative to the motor rotor data. The carbon brushes are selected to suit the application and the place of use.

The travel range of the brush rocker is adjusted, allowing the rollers to rest during normal operation and thus saving wear. Customers looking to source a slip ring motor with a short-circuiting and brush-lifting device benefit from the fact that Menzel is a one-stop shop for motors featuring this facility, offering selection, configuration, manufacture, testing and commissioning.

www.menzel-motors.com