www.ptreview.co.uk

08

'23

Written on Modified on

Yamaha and distributor ANS Elektronik deliver solutions for advanced manufacturing

Product innovation and investment in services are enabling and future-proofing Europe’s leading OEMs and assemblers.

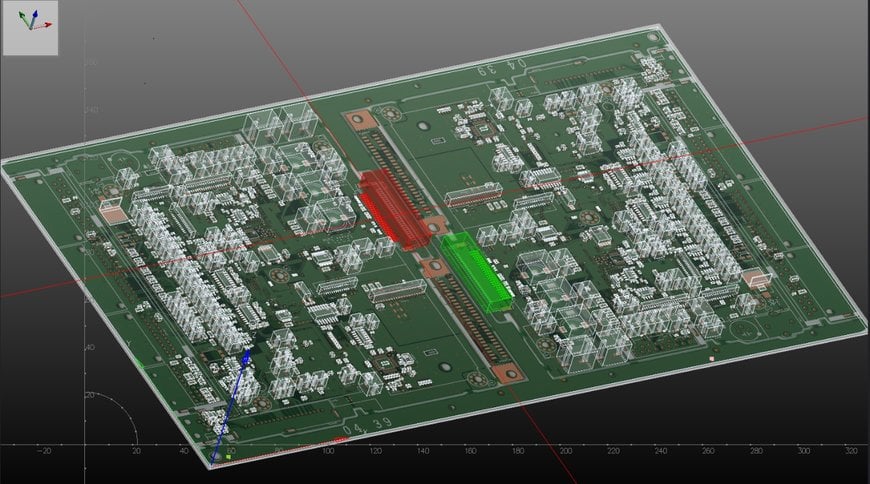

With the advanced YR series for surface-mount assembly, Yamaha Robotics SMT Section and distributor ANS-Answer Elektronik are expecting further success in their long-standing partnership serving the high-tech community in Germany, Austria, and Switzerland.

Electronics manufacturing in this region comprises OEMs and EMS businesses active in rapidly advancing, high-growth market sectors. They include automotive electrification - with its current focuses on automated driving and power electronics - advanced industrial controls and connectivity leveraging Industry 4.0 technologies, and the latest communication and networking infrastructure including 5G wireless.

“Our customers need accuracy and flexibility in their surface-mount assembly lines, with high speed, and the ability to handle all the latest component technologies and package geometries. They invest frequently to keep their capabilities at the cutting edge, and they need a fantastic return each time,” explains Sebastian Glitsch, General Manager of ANS. “That’s where we make the difference, with our ability to supply and support the best assembly and test equipment in the market. Our connection with Yamaha is a big part of that value proposition.”

He goes on to highlight aspects that help present a persuasive offer for customers, including high placement performance in relation to mounter footprint that makes factories more space-efficient. “Also, there are many clever and time-saving features that automate tasks such as changing the printer stencil and loading component feeders. These minimise stoppages, whether production involves frequent changeovers or large batches. There are automated tools for generating placement and inspection programs, which help accelerate new product introductions.”

In addition, Sebastian Glitsch points out that Yamaha frequently introduces new features that are attractive and accessible to customers. These include the YSUP 3D user interface, smart-factory software with the latest IIoT protocols for seamless IT/OT connectivity, and the all-new YR series machines that have arrived within the past year. “We can always offer a solution that meets present needs optimally and is also future-proof,” he explains.

Daisuke Yoshihara, Yamaha Sales General Manager, joined by Ulf Neyka, Yamaha Sales Manager for DACH region, commented, "Our partnership with ANS-Answer Elektronik has made a significant contribution to our strong business performance in Europe. Their local knowledge and expertise have added value to the solutions we can offer, building on the high standards of performance and quality engineered into all Yamaha SMT equipment.”

Founded in 1994, ANS-Answer Elektronik has grown with Yamaha’s SMT business unit in Europe. Their connection began 26 years ago with the Yamaha iPulse generation of mounters and strengthened as Yamaha introduced the YS series of screen-printing, placement, and inspection machines and intelligent component handling systems. ANS has achieved notable successes with the 1 STOP SMART SOLUTION, which covers the entire SMT assembly sequence and includes unique and advanced software tools to maximise productivity and enable smart-factory management.

Now, with the new-generation YR series platforms ANS is looking forward to the possibilities the new machines bring with their increased capabilities and advanced features. They include the latest dual-lane machines that allow total flexibility to configure the two lanes indepdendently and ensure maximum performance unaffected by the settings of the other. “That’s a market-first for dual-lane equipment,” comments Sebastian Glitsch.

He concludes, “We are excited about the advantages the new YR series will deliver for our customers. This represents the start of a new chapter in our relationship with Yamaha that will lead to even greater success.”

www.yamaha-motor-robotics.com