www.ptreview.co.uk

19

'23

Written on Modified on

INLINE COLOR MEASUREMENT ON THE EXTRUDER LINE

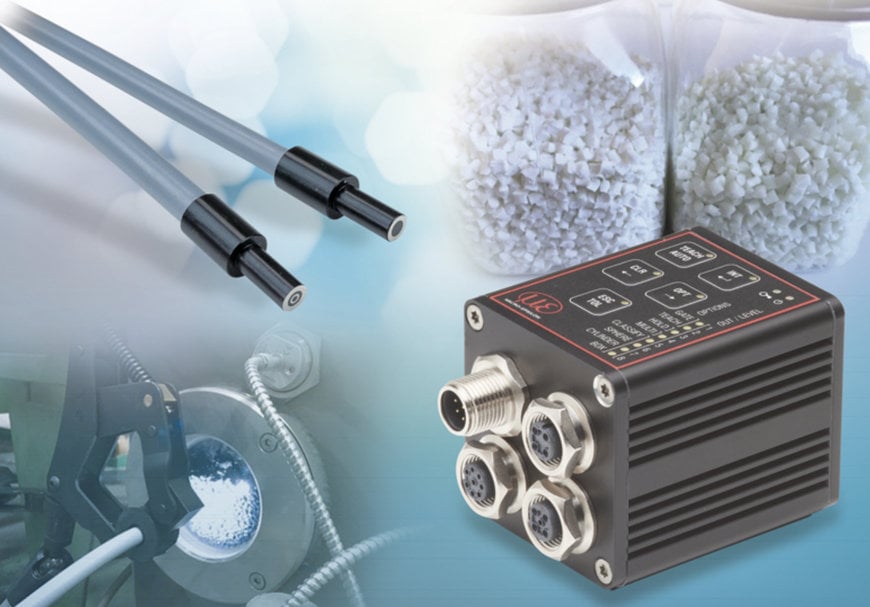

Micro-Epsilon colorSENSOR CFO sensors are used for reliable color inspection of the granulate. To save resources and costs, this test is carried out very early in the process.

Polyamide plastic is finished by extrusion and strand pelletizing. Different product groups are created, which must comply with a specific color value depending on their specifications. Currently, raw materials from different manufacturers and qualities are frequently used to maintain the delivery capability. There is therefore a particular need for testing when the raw material has to be recolored and mixing ratios have to be adjusted, but also in the event of possible malfunctions in the process. The color values of the granules may be changed. The result is a product that does not meet specifications, which wastes money and energy.

A True Color sensor from the colorSENSOR CFO200 series by Micro-Epsilon is therefore used to detect the fluctuating color values of the pellets. The sensor measures the color of the pellets through a sight glass in the suction box of the finished product conveyor and reliably detects the smallest color deviations (∆E < 1) from the programmed reference value. The recorded values can then be forwarded directly from the sensor to a higher-level control system via a signal output.

www.micro-epsilon.com