www.ptreview.co.uk

02

'23

Written on Modified on

MOLYWORKS INTEGRATES 3D SYSTEMS' DMP FLEX 350 INTO ITS MANUFACTURING WORKFLOW

DMP Flex 350’s large print volume and vacuum chamber enable MolyWorks to be more agile and efficient than with previous metal 3D printer.

3D Systems announced that MolyWorks, a California-based, developer of the circular economy for metal, has integrated the DMP Flex 350 into its manufacturing workflow. As a result, MolyWorks has recognized significant efficiency improvements in its production process, and opportunities to enhance the breadth of capabilities by delivering additively manufactured end-use parts to its customers. With these advantages, MolyWorks has grown its customer base, including the work the company is conducting alongside the United States Air Force to evaluate 3D-printed flight-critical parts.

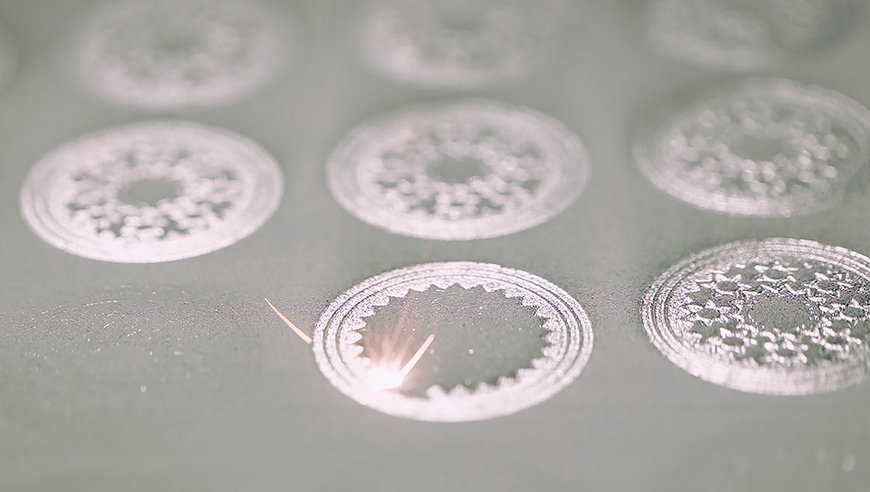

Metal additive manufacturing (AM) has become a trusted technology to create airworthy parts with reduced weight and improved performance. With the ability to facilitate rapid design and production of consolidated components, AM helps accelerate the certification process and optimizes the entire supply chain. As the producer of metal powder that is used to produce high-quality metal parts, MolyWorks needed an AM solution that seamlessly integrated with their workflow. They chose 3D Systems’ DMP Flex 350 due to its unique vacuum chamber architecture which is critical when manufacturing parts from titanium — a material that has become a standard alloy for aerospace applications. The vacuum chamber maintains a low oxygen environment (<25 ppm) which reduces argon gas consumption and produces an excellent surface finish with fine feature detail. MolyWorks is also taking advantage of the DMP Flex 350’s optional removable print module (RPM). Being able to swap out the RPM allows their team to perform a quick cleanout and get the machine back up and running with another material in a short amount of time.

MolyWorks uses its DMP Flex 350 to produce parts not only for customers, but their own products as well including their mobile atomization unit, The Greyhound.

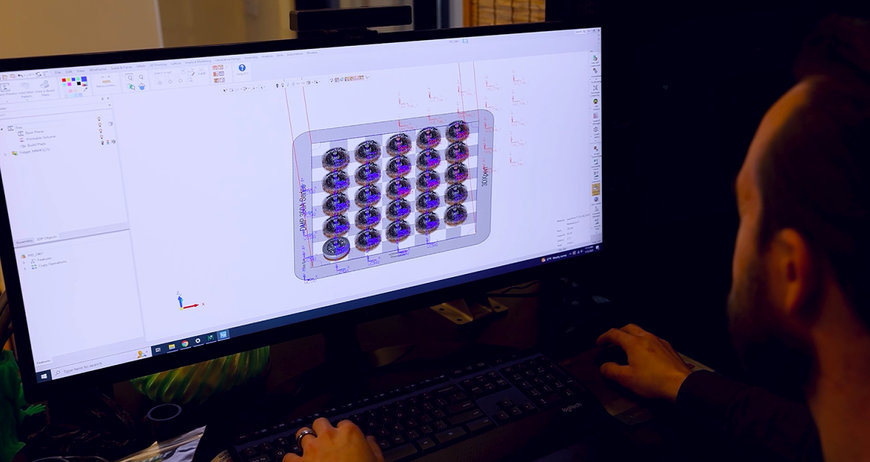

Additionally, the DMP Flex 350 includes Oqton’s 3DXpert software which supports every step of the additive manufacturing workflow from design to post-processing, to quickly and efficiently transition from a 3D model to successfully printed parts. This single software solution for modelling, simulation, and manufacturing eliminates the need to rely on multiple software packages. Efficiencies driven by 3DXpert can enable up to 75% faster file-processing time, and increase productivity by up to 40%.

www.3dsystems.com