www.ptreview.co.uk

18

'23

Written on Modified on

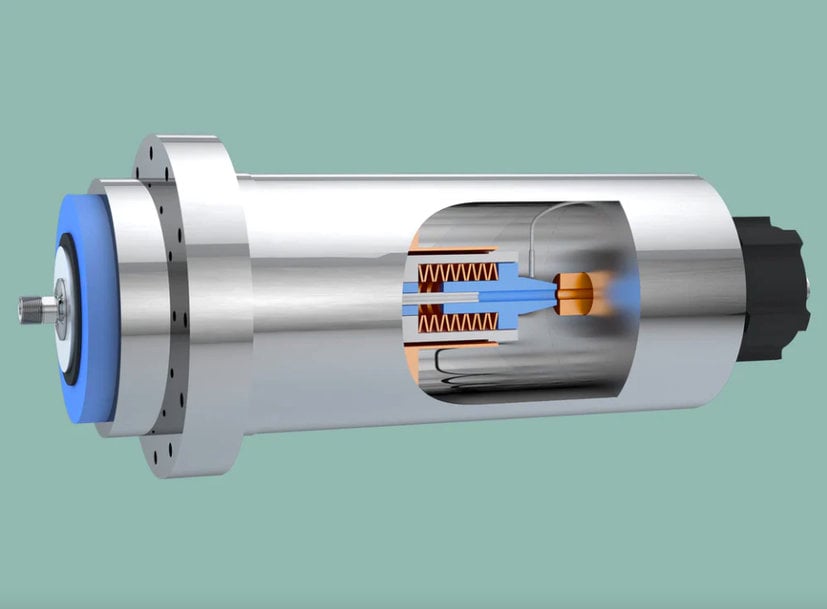

CONTRINEX OFFERS SMART INDUCTIVE SENSORS FOR COMPACT MACHINE-TOOL SPINDLES

Compact machine-tool spindles benefit from the use of smart inductive sensors that prevent incomplete engagement during automatic tool changes.

Modern CNC machining centres cope with a range of materials, workpieces and cutting speeds that require different tool characteristics; spindles with automatic tool-changing are key to optimizing throughput. If a new tool fails to engage completely, damage to the tool, the workpiece or the spindle results.

Designers specified Smart Sensors from Contrinex, embedded in the body of the spindle, to monitor the position of the tool during changes; any noncompliant measurements stop the process, triggering an alarm.

Customer Values

Designers specified Smart Sensors from Contrinex, embedded in the body of the spindle, to monitor the position of the tool during changes; any noncompliant measurements stop the process, triggering an alarm.

Customer Values

- Embeddable inductive Smart Sensor monitors drawbar position, detecting incomplete tool engagement and inhibiting further motion before damage occurs

- Single-sensor positional-control system is non-complex and highly affordable

- Embeddable M12 sensor fits snugly in the limited space available

- Industry-standard IO-Link connectivity provides a single interface to the machine control system

- Cumulative operating data for predictive maintenance, including temperature and operating-cycle count, is recorded in on-board data storage

- Sensor configurations are stored locally, allowing plug-and-play replacement of sensors when needed

- Proven technology ensures highly reliable fit-and-forget operation with no manual intervention

Specific Product Advantages

- Robust, metal-cased inductive Smart Sensors are ideal for easy integration

- Multi-channel monitoring circuitry allows users to define up to 16-bit customized output thresholds

- Sophisticated sensing electronics deliver dynamic linear-distance measurements with a resolution in the micron range

- High-speed device-to-device communication enables decentralized data-processing and decision making

- Dedicated service-data blocks hold device-specific data including product ID, location and serial number

- Visible LED indicators enable sensors to self-identify on demand, simplifying commissioning and trouble-shooting routines

- Industry-standard -25°C to +70°C operating range

To learn more about Contrinex's Smart Sensors solution, visit: https://www.contrinex.com/en-ch/products/dms-smart-06-mm?variant=42671621636247