The new generation of linear axes: Ideal for semiconductor production

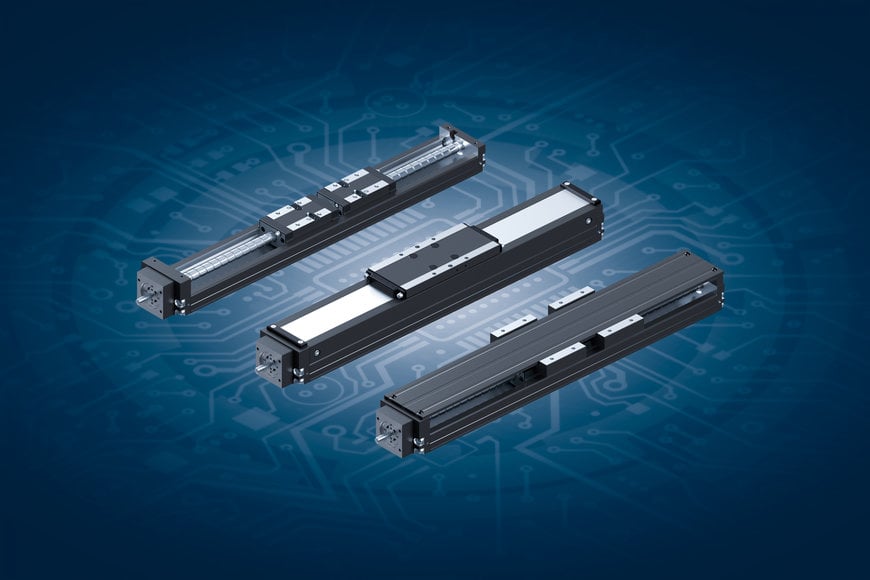

Quick, dynamic und highly precise: Bosch Rexroth is expanding its range of linear axes by adding a new generation of PSK precision modules.

- Highly rigid and precise: Steel profile as frame with integrated guideways

- Digital engineering: Freely configurable with numerous options

- Easy to integrate thanks to compact design

For the new generation of PSK precision modules, the developers at Bosch Rexroth have increased the rigidity of the frame. Two accuracy classes cover usage scenarios for various applications in an economical manner. With a ball screw assembly sealed on both sides and an extended lubrication concept, the new PSK precision modules from Bosch Rexroth meet the requirements in semiconductor production and the electronics industry even better than before.

The range includes three different sizes. The modules are based on a smooth, compact and rigid precision steel profile as the frame with integrated guideways. The side of the ground reference edge can be selected. This speeds up assembly and makes it easier to align the axis. Compared to previous models, the frame offers greater torsional rigidity and higher planar moments of inertia.

With two accuracy classes, precision modules from Bosch Rexroth meet various mechanical requirements in clean production in an economical manner. The optional magnetic sensors can be set across the entire travel range.

At the same time, Bosch Rexroth has expanded the lubrication concept to include other lubrication types. The standard version has initial greasing using standard industrial lubricants. The runner block and ball screw assembly can also be preserved rather than greased to allow the use of approved greases later on. At the same time, the modules can be connected to central lubrication systems with liquid grease. Automated relubrication increases operational safety as human errors when it comes to observing lubrication intervals are ruled out. Engineers also have greater freedom because they do not need to provide access for manual lubrication procedures.

Even the engineering process is a breeze: Thanks to the simple selection procedure using the selection and design tool LinSelect and subsequent online configuration including the drive, the customized PSK solution can be finalized and ready for ordering in a matter of minutes. The online configurator guides users easily and reliably through the product specification process and is available in most common languages.

Bosch Rexroth thus offers a fully digital engineering process from design through to ordering including pricing and the provision of CAD data. The order confirmation also includes a clear material number which can be used to reorder the particular linear axis without having to reconfigure it. The user also receives the associated 2D and 3D CAD data straight away.

www.boschrexroth.com