KEBA Industrial Automation @ SPS 2022

This year, KEBA Industrial Automation chose as its motto for the SPS trade fair: „It’s All About Listening. And Understanding“. But what has listening and understanding got to do with automation? More than you might think!.

- Trade fair motto: „It’s All About Listening. And Understanding“

- KEBA focuses on digitalization, HMI, easy integration and operation of robotic solutions, and the KEBA platform for software and hardware: Kemro X

- Gamification: Visitors can register for games and thus evaluate operating devices in a playful way.

Martin Schwarz, CSO KEBA Industrial Automation: „Especially in today’s world with its fast communication formats, rapidly changing markets, products, and corporate strategies, being a good listener is becoming even more important. Only by listening carefully we can understand what our business partners really want. Only those who listen and understand will be able to translate the requirements into unique, tailor-made solutions.“

Gamification

In the run-up to the trade fair, KEBA invites visitors to register for games at the booth. For games from the 80s such as 'Moonlander', 'Space Invaders' and 'BrickBuilder', different KEBA operating devices will be used. Visitors can get to know different operating approaches, evaluate them and give feedback to KEBA employees. "We chose this format because it is a unique way for visitors to actively engage with the HMI approaches. This creates a dialog, which in turn contributes to the trade fair motto 'It's all about listening. And understanding'," says Filip Miermans, Head of Marketing and Communications at KEBA Industrial Automation.

Highlights of KEBA Industrial Automation at SPS 2022

With over 330m² of booth space, the KEBA team will highlight the following topics:

Positioning:

- KEBA is a full-liner, making us the perfect partner for companies who are looking for depth and breadth in technology and automation.

- Furthermore, the automation specialist from Austria will emphasize its deep industry experience, such as in the plastics industry or robotics.

- A third focus is to underpin the fact that KEBA is strong in developing solutions together with customers – keyword: customizing.

Content focus:

connectivity, energy efficiency and digitalization – challenges that run through all industries. Some concrete examples at product level:

- Digitalization: solutions for vibration monitoring and sensorless condition monitoring of a complete powertrain - based on the Kemro X platform and applicable to any application.

- Energy efficiency: active supply units, efficient operation of our robotics

- Connectivity: standardization of our interface world with focus on OPC-UA and the corresponding information models with the goal of "Plug & Produce”

Ketop Safe Wireless: one control unit for many machines

As companies grow, so do their production lines and machine parks - it is not uncommon for different machine generations from several manufacturer brands to come together. These should be able to effectively communicate with each other but also be operated in a uniform way.

What is needed is a highly flexible one-for-all HMI solution that is based on the modular principle. If this is then also wireless, machine and robot operators benefit from maximum flexibility and efficiency and operate where they have the best view of the process.

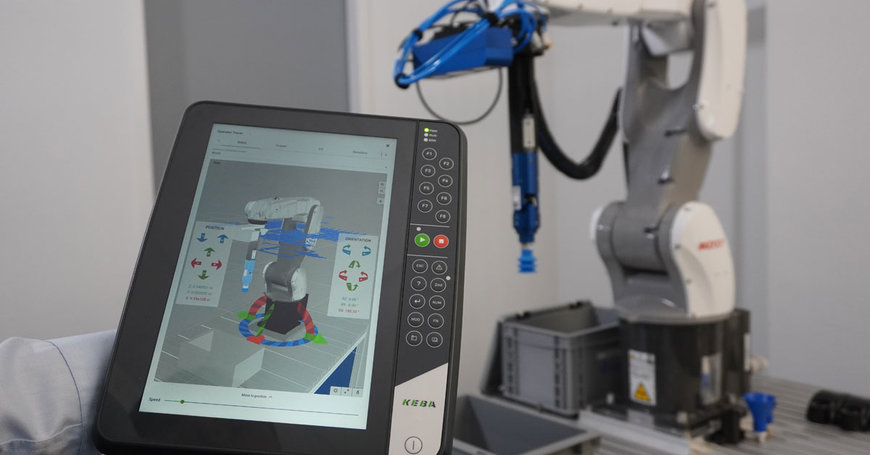

Easy operation and programming of robotic solutions

Requirements for robots are undergoing dramatic changes. Humans and robots are working together more and more frequently, areas that are strongly characterized by manual work are becoming increasingly automated, mass production is replaced more and more frequently by small batch sizes, and individual customizing is in ever greater demand.

But do you really need someone with special know-how for every robot customization? Can't the integration of robotics solutions in the production environment be made simpler?

The answer is: yes, it is possible to implement or adapt robot applications quickly and independently, even without expert knowledge or extensive training. The prerequisite for this is an appropriate software solution, such as drag&bot, with which industrial robots can be easily operated and programmed by production employees. Read more in the interview on our blog

Kemro X – the KEBA automation platform for hardware and software

As a complete automation system for hardware and software, Kemro X covers everything a machine manufacturer needs for its smart factory: All mobile and stationary panels, drives and hardware types as well as the engineering tool are built in.

The system has a modular structure and the modules can be used like apps on a smartphone. Modules from KEBA, customer-specific or Linux-based standard modules can be used. Linux-based openness allows customers to integrate their own software modules as well as third party software. This allows them to protect their know-how and maintain their independence.

The open system architecture enables the required inter-process communication. Following the principle of a modular system, KEBA has developed an extensive range of software units that the machine manufacturer can use for all automation projects: from engineering tools to simulation tools. Read more

For more information about KEBA at the SPS, visit www.keba.com/sps and our BLOG

www.keba.com