Accelerating the digital transformation of the machine tool industry with Siemens Xcelerator

Under the motto "Accelerate digitalization for a sustainable tomorrow", Siemens will be demonstrating at this year's AMB how the enormous potential for optimizing machine tools can be utilized thanks to the continuous analysis of production data.

Under the motto "Accelerate digitalization for a sustainable tomorrow", Siemens will be demonstrating at this year's AMB how the enormous potential for optimizing machine tools can be utilized thanks to the continuous analysis of production data.

- Siemens Xcelerator includes selected portfolio of IoT-enabled hardware, software, and digital offerings as well as a marketplace

- Offerings for the machine tool industry part of Siemens Xcelerator

- Software applications for cloud, edge, and own servers with numerous innovations for the machine tool

- First partner applications based on Industrial Edge for Machine Tools, the open ecosystem for IoT

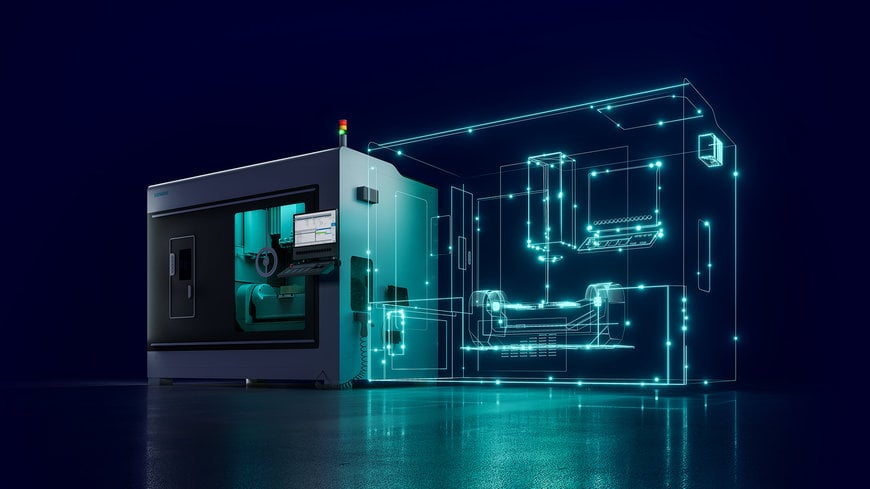

With the open digital business platform Siemens Xcelerator, IoT-enabled hardware and software, the company demonstrates how the real world can be connected to the digital world. Such a portfolio accelerates the digital transformation and enables flexible and sustainable action both in the construction of machines and in their application.

Apps for the machine tool also part of Siemens Xcelerator

Under the name Xcelerator, Siemens therefore launched an open, digital business platform to the public in June. In this way, the company wants to enable customers of all sizes in the fields of industry, buildings, grids, and mobility to accelerate their digital transformation and increase value creation.

The business platform makes digital transformation easier, faster, and scalable. It comprises three cornerstones: a curated portfolio of internet of things (IoT) enabled hardware, software, and digital services from across Siemens and certified third parties; a growing ecosystem of partners; and an evolving marketplace to facilitate interactions and transactions between customers, partners, and developers. With applications such as Manage MyResources /Tools, Manage MyResources /Programs, Analyze MyPerformance /OEE, Manage MyMachines, Manage MyMachines /Remote and Analyze MyMachine /Condition as well as the Industrial Edge for Machine Tools platform, Siemens also provides offerings for machine tools via Siemens Xcelerator.

Numerous innovations for machine tool apps

In the area of work preparation, Siemens is bringing several innovations to the AMB in Stuttgart this year for the applications Manage MyResources /Tools, Manage MyResources /Programs and Analyze MyPerformance /OEE. The apps provide intelligent resource management that allows production orders to be prepared smoothly by providing the right tools and NC programs. A central solution at the manufacturing level manages real instances of tools, tool components and programs for parts production, using the insights from the CNC. Workflows in machining environments are optimized, tool circulation and tool inventory are efficiently organized. The efficient use of production capacities can be improved by analyzing overall equipment effectiveness (OEE). All three applications offer innovations, for example with broader connectivity even for CNC machines that are not equipped with Sinumerik.

This means that nothing stands in the way of a shop floor-wide connection of machines to resource management. In addition, Manage MyResources /Tools can now provide further valuable insights into tool usage, such as the duration of the different life phases for certain tool types. Also new is the possibility of more efficient tool planning with reservation of tools for a machine or production order or as a standard tool. With the help of unloading lists for balancing, the planning of tool requirements will become even more efficient in the future. For Manage MyResources /Programs, additional use cases can now be covered by the possibility to add additional file types such as drawings to NC packages. In Analyze MyPerformance /OEE, the machine status can now be configured individually. In addition, the app provides detailed insights into workpiece statistics and production progress.

For the monitoring of machines during operation, Siemens is also presenting innovations for the already available apps Manage MyMachines, Manage MyMachines /Remote and Analyze MyMachine /Condition in Stuttgart. The apps analyze the data generated during workpiece machining, which can then be used to improve maintenance planning. Unexpected changes, for example in machining performance or vibration, indicate disturbed processes.

In the new version of Manage MyMachines, it is now possible to examine reports of technical faults even more closely. Also new: The now seamless transition between the two apps Manage MyMachines and Manage MyMachines /Remote further improves the user-friendliness and efficiency of service calls. Manage MyMachines is now also available with broader connectivity, which now supports further controllers from other manufacturers.

Open Siemens Industrial Edge for Machine Tools ecosystem

Openness to partners is demonstrated by the Industrial Edge for Machine Tools ecosystem. Based on the Siemens Edge Platform, Schunk, manufacturer of gripping systems and clamping technology, develops its iTendo Service. By combining sensor data from the tool tip and data from the NC, Schunk wants to help machine tool operators improve the machining process and, for example, prevent tool breakage.

Further information on Siemens at AMB 2022 at www.siemens.com/press/amb22 and www.siemens.com/amb.

Further information on Siemens Xcelerator at https://sie.ag/3u6Ugte.

www.siemens.com