www.ptreview.co.uk

02

'22

Written on Modified on

FRAUNHOFER TECHNOLOGY PROVIDES ENVIRONMENTAL SATELLITES WITH VISION

The Fraunhofer Institute for Microengineering and Microsystems IMM and the Fraunhofer Institute for Applied Optics and Precision Engineering IOF have developed various core components for the optical system of the hyperspectral satellite.

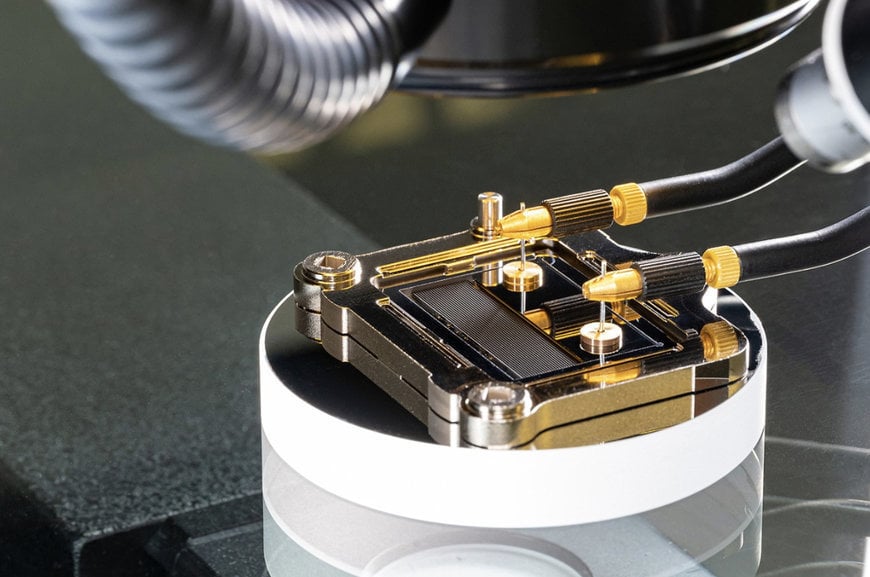

The heart of the satellite: a double slit module from Fraunhofer IMM

To conduct its analyses, the satellite detects the light from the sun that is reflected by the Earth. However, the wavelength range from 420 to 2,420 nanometers, i.e., from visible light to deep infrared, is too big to be recorded with just one spectrometer. This is where a technology from Fraunhofer IMM comes to the rescue. “We have manufactured a high-precision double slit module that directs the incident light into two detectors,” explains Stefan Schmitt, group manager at Fraunhofer IMM in Mainz. By their very nature, the two slits are kept a little apart, meaning they do not look at the same points on the Earth. “It therefore takes a fraction of a second for the second slit to see the same part of the Earth as the first,” says Schmitt. This offset must be identified with maximum precision to enable the recordings to be overlaid and to achieve the required resolution of 30 meters.

The key to this is the exceptionally precise method used to manufacture the double slit module, which is only possible using silicon technology. “Although the techniques that we have available at the institute are well placed to meet these requirements, there were still many challenging details to consider,” recalls Schmitt. For example, the rectangular slits used initially did not prove to be mechanically stable enough. The researchers therefore went on to produce slits with a graduated cross-section. “Despite extensive simulations and analyses by our partners, we had to change the design and other requirements while the process phase was underway. Things like this happen from time to time when breaking new ground, so we were prepared for it,” says Schmitt. The researchers also had to produce other module components – such as those used to deflect light or suppress scattered light – to the highest degree of precision using materials suitable for space applications such as aluminum, stainless steel, nickel and Invar, whose properties had to be precisely measured and documented. Another tricky aspect concerned assembling the double slit module. “The tolerances were smaller than five micrometers, so less than a tenth of the size of a strand of hair,” says Schmitt. All of this was completed with aplomb.

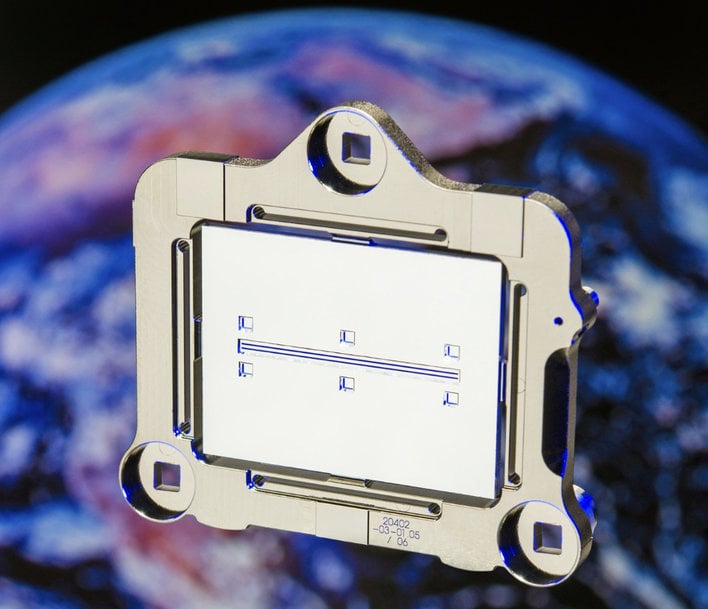

Light and precise: metal mirrors from Fraunhofer IOF

Fraunhofer IOF also contributed its expertise to the satellite: The institute is one of the best metal optics developers in the world and produced all of the metal mirrors used in the EnMAP optics. “For space applications, the mirrors not only need to have an extremely smooth surface and be shaped with an exceptional level of precision – they also need to weigh as little as possible,” says Dr. Stefan Risse, project manager at Fraunhofer IOF in Jena. “This was an area where we could even exceed the requirements specified: Instead of the required roughness of 1 nanometer rms (root mean square), our metal mirrors demonstrate a roughness of less than 0.5 nanometers rms when measured in white light (50x magnification). We were also able to keep the permissible shape deviation not only to 18 nanometers rms, but in some cases even to less than 10 nanometers rms.” To achieve this, the researchers used aluminum on which they deposited an X-ray amorphous metal alloy of nickel and phosphorus. In terms of its structure, this thick film has similar properties to glass and is highly suited to machining with diamond tools and polishing to a high level of finish. With respect to the final shape of the metal mirrors, the team of researchers subjected the mirrors to corrective procedures such as Ion Beam Figuring (IBF).

In addition to the low surface roughness, a lightweight design was another important quality characteristic for the mirrors. The technique employed by Fraunhofer IOF delivered in this respect too. “We were able to reduce the mass by more than 40 percent using one of our patented techniques – and now, the use of additive processes means that savings of up to 70 percent are possible,” says Risse. The team managed to achieve this by creating a structure for the mirrors that resembled a capital in a church: Cross bores meeting at right angles connect the front and rear of the mirror, and the column structure that is formed supports the surfaces. The front and rear of the mirror are closed, giving the element a high degree of mechanical stiffness. In total, the team manufactured eleven ultra-precise metal mirrors plus highly reflective silver and gold layers for EnMAP and also coated the glass optics by applying a thin layer with low refractive power to the glass.

www.fraunhofer.de