www.ptreview.co.uk

07

'22

Written on Modified on

WITH MAXIMUM PRECISION – LINEAR MOTOR AXIS INCREASES PRODUCTIVITY

In order to remain competitive in the global market, optimisation potentials within the process chain must be consistently utilised. There are also growing requirements with regard to process and machine safety, which pose new challenges for every company.

A faster throughput of parts with increasing quality requirements while always keeping the safety of the employees in mind – the future is demanding. If all these factors are then optimally implemented and adapted by redesigning a production machine and integrating a precise linear motor axis, considerable progress can be generated and real customer benefits created.

DynaMotion GmbH from Ilmenau in Thuringia, Germany, focuses on customised drive solutions. With their expertise, they plan and design special machines with individualised approaches that focus primarily on special drive technology. “You call DynaMotion when you need drive technology outside of the standard range”, says Stefan Schmitz-Galow, Managing Director of DynaMotion GmbH. “We redesigned a thermal forming machine for one of our customers and were able to significantly increase process and machine safety, as well as productivity”.

Linear motor axis as new machine centrepiece

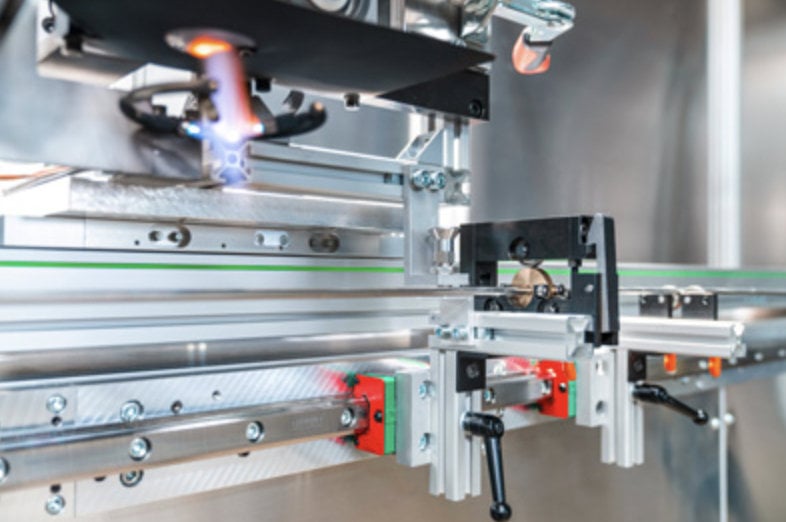

A linear motor axis from the HT-L series from drive specialist HIWIN is used as the drive. When selecting the right drive element for the feed, the main focus was on the precision and synchronisation of the movement.

“The thermal forming process is a very sensitive procedure in which the smallest fluctuations in speed or temperature have a major impact on the end product. That is why it was important to find a drive that guarantees us absolutely smooth acceleration and constant movement. A stick-slip effect would destroy the sensitive end product”, explains Stefan Schmitz-Galow (DynaMotion GmbH).

The linear motor axis HT-L is based on an aluminium base profile in which the linear guideways are integrated. On the one hand, these absorb the weight and process forces, and on the other hand they ensure the exact guidance of the carriage. The axis is driven by an iron core linear motor. The induced current of the motor coils generate a magnetic field that varies with time and interacts with the constant magnetic field of the stator. The resulting force is used to generate a linear movement.

Due to the iron core linear motors used in the axis, our customer was initially sceptical as to whether the linear axis would even be accurate and smooth enough for the machine. However, thanks to the integrated high-resolution distance measuring system, I knew from the beginning that the axis from HIWIN could do exactly what we needed”, says Stefan Schmitz-Galow (DynaMotion GmbH) with satisfaction.

Thanks to the installed four-metre-long linear axis, it is now possible to manufacture significantly more product. Stefan Schmitz-Galow (DynaMotion GmbH) explains: “A shaft axis used to be installed here as the drive. To prevent the shaft from swinging open, the stroke was limited to a maximum of two metres and the travel speed was also limited by the drive element. By using the linear motor axis, we have been able to improve in several respects: the feed rate can now be kept extremely constant, we have adapted the speed perfectly to the process, and we can fully utilise the maximum speed of the linear axis during the return stroke. This significantly improves the ratio between set-up and production time. So by using the linear motor axis, we were able to achieve a 100% increase in productivity, so to speak”.

Drive technology: Specialists in their field

“We also see ourselves as specialists in drive technology, but in the design of special machines. It goes without saying that we are also familiar with HIWIN and its products, and knew it as a top manufacturer in the field of drive technology”, says Stefan Schmitz-Galow (DynaMotion GmbH). “Above all, the sealing concept of the linear motor axis was a key feature that impressed us during the selection process. It is unique and fantastically made”.

The steel cover strip is already available as an option as standard on HIWIN linear axes and prevents foreign bodies, such as accumulating dust or splinters, from entering the interior of the axis. An additional sealing air connection protects against contamination due to the overpressure created in the axis.

Stefan Schmitz-Galow (DynaMotion GmbH) says with praise: “We are totally impressed by the linear motor axis and its design. Especially because it is so well protected. We would certainly like to use HIWIN drive technology again and again”.

www.hiwin.com