www.ptreview.co.uk

18

'22

Written on Modified on

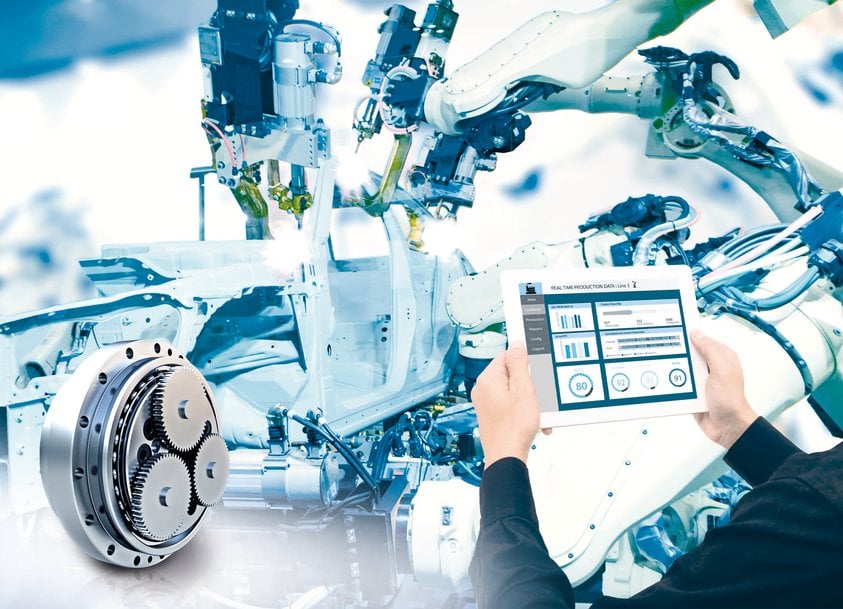

Robotics: Nabtesco starts predictive maintenance project

In the age of Industry 4.0, no one can get by without predictive maintenance. Nabtesco, the world market leader in the field of robotic gears, is therefore working on solutions for real-time monitoring of robots by means of digital gear models. The goal: predictive maintenance for maximum cost effectiveness and robot availability.

For robotic gears there are normally fixed maintenance intervals. After a defined period of time or operating life they are replaced – regardless of the actual state of wear. Depending on the application requirements and the period and scope of use, however, the gearboxes are subjected to varying levels of strain in practice. The load on the individual axes also varies. This is where Nabtesco’s project for predictive maintenance starts. Although the project is still in the initial phase, it has enormous potential.

Gear data directly from the manufacturer

The cycloidal gear specialist and world market leader in the field of robotic gears is the first gear manufacturer in the field of robotics to open the black box of gears to robot manufacturers with a Nabtesco add-on for the control of robots that provides gear-specific data and characteristics. The goal: A digital twin of the haptic gear with its relevant properties. Real-time monitoring of robots in the future will rely on real digital gear characteristics from Nabtesco on the basis of the serial number, because this allows an individual snapshot of the robot load and therefore an analysis of the remaining life of the single gears.

Condition monitoring for maintenance on demand

The system will make use of data values that are already available. Speed and torque characteristics, for example, in combination with empirical data from more than 35 years of gear development, allow detailed inferences about the state of the gearbox and therefore its remaining life. Constant monitoring of the cycloidal gears would facilitate maintenance on demand. It would also allow timely identification of impending failures, while facilitating planning of service calls, reducing maintenance and eliminating unplanned machine downtimes. The result would be more efficient production processes and increased productivity.

Software replaces sensors

Compared to external sensors the software-based solution offers numerous advantages, such as lower costs, reduced system complexity and improved data quality. Another factor: Not all data can be acquired by means of sensors. This applies for example to rigidity – and of course to empirical data from development. Since gearboxes undergo extensive testing before being marketed, Nabtesco knows exactly how the gearbox will behave as a result of wear, for example, or how it will be affected by temperature and lubricants. All of these parameters need to be available to the robot controller.

Smart cycloidal gears for IIoT applications

The planned digital services will allow Nabtesco to monitor the digital twin of the gear in the robot controller, which will open up innovative perspectives for modern maintenance concepts in the context of Industry 4.0. Currently the project is in the development phase. Two stages are planned: a Nabtesco add-on with generalised data about a particular gear model, and an additional upgrade for even better accuracy with the specific data on the gearboxes that are actually installed.

www.nabtesco.com