www.ptreview.co.uk

28

'22

Written on Modified on

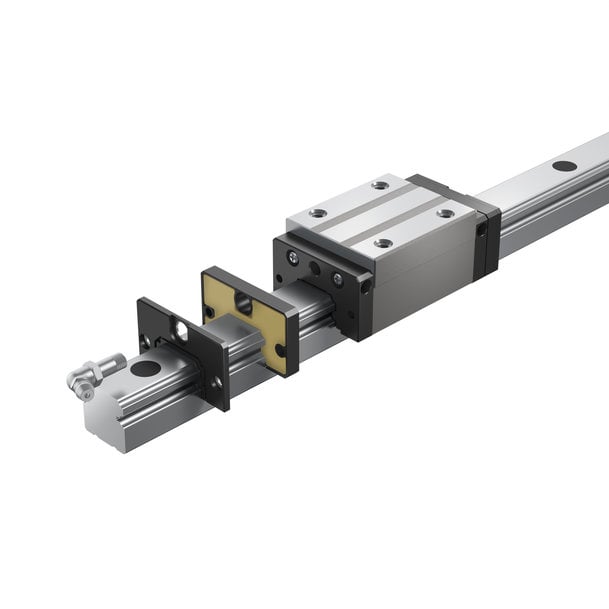

Timber plant reduces downtime with NSK linear guides

Thanks to the adoption of NSK's linear guides with K1 lubrication units, a timber manufacturer managed to reduce conveyor downtime by a factor of more than 12, prompting annual cost savings of more than €77,000.

The British timber manufacturer supplies wooden beams to the building industry. At one production station, a conveyor system transports the beams to a processing machine, performing forward and backward motion with rapid changes of direction. Due to the demands of this operation the company had to replace the conveyor’s linear guides every two weeks on average, a situation that was clearly unacceptable.A request arrived from the company’s management team asking NSK for recommendations on how to extend the service life of the linear guides. Analysis of failed units by NSK experts revealed that they were not capable of withstanding the high loads which occur at each change of direction. In addition, the linear guides sometimes jammed completely due to the intrusion of wood particles.

NSK's recommendation was to adopt NSK linear guides equipped with fully integrated K1 lubrication units. K1 units progressively release lubrication oil (embedded in the pores of a polyolefin resin) on to the raceway over a very long time period.

Since the upgrade, the system has been running for six months without a single failure. The service life of the linear guides has thus increased by a factor of more than 12, with a corresponding reduction in related costs for material and downtime. In total, NSK's cost benefit analysis showed annual savings of around €77,800.

The K1 lubrication unit is available for any linear guide in NSK's range. As shown by this example, linear guides equipped with the K1 are maintenance-free across a very long service life, even (and especially) under adverse operating conditions.

Along with the retrofit of the conveyor system, NSK provided comprehensive linear guide training for the company’s maintenance personnel. Among the topics covered by the training were: differences in materials; product selection based on load capacity; and different types of linear guides and their options. NSK also explained the function of the K1 lubrication unit.

1) The linear guides in a conveyor unit at a timber plant required replacement every two weeks on average. Photo: Sergei Pronin | Dreamstime.com

2) Linear guides with K1 lubrication units achieve long service lives even in tough operating conditions, such as those in the timber manufacturing industry.