www.ptreview.co.uk

21

'21

Written on Modified on

Seven opportunities for optimization

Do you want to produce safe and nutritious food? Satisfy the desire for greater product variety and product selection? Be able to trace your products? All while increasing your yield, improving your throughput level and reducing giveaway? Then start looking at your setup today and consider which areas can be optimized. Every detail counts: each step of a process, each piece of information, each new demand and especially each piece of meat, poultry, or fish.

1. Are you maximizing the shelf life of your products?

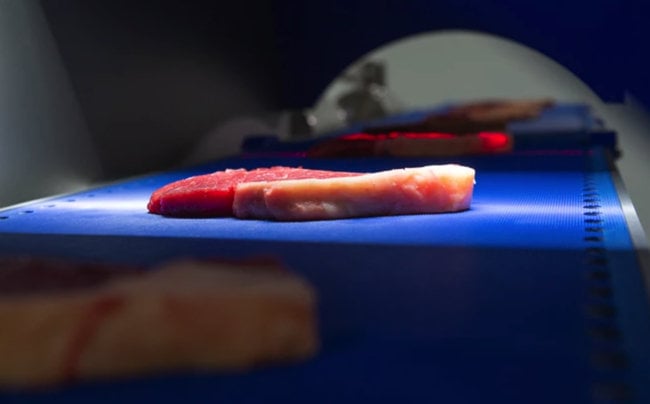

Every process counts when it comes to raw materials with limited shelf life. Moving raw materials between production areas and different processes needs to happen fast. A highly automated production line reduces processing time with multiple benefits to the value chain. Here, the use of intelligent technology can greatly improve efficiency and safety in material handling and throughout the rest of the system.

A setup that ensures no contact between raw materials and the end product, as well as minimum manual handling, will lower the risk of contamination as well as help extend shelf life, maintain nutritional properties, and support food safety. You can raise efficiency further with a quality control system that monitors performance and responds quickly to any deviation

2. Could your quality control be improved?

Every piece of information counts in an industry that needs to meet the highest standards. In every food processing plant, quality control is crucial to ensure safety, hygiene, and traceability while also meeting the demands of authorities, customers, and consumers. A quality control software application reliably collects and integrates quality control inspection data, enabling you to increase the quality and value of your processes and products. With cross-correlation of multiple data streams, you will get rapid, cost-effective means of quality assurance – totally paperless and automated.

Smart, data-driven processes can address any quality issues immediately, so you do not have to deal with problems further down the line or on completion of an order.

3. Is your production flexible and fit to evolve?

Every demand counts, whether it is new products, new features, or something else. A flexible food processing setup is geared toward constant changes in the market. There is an increase in demand for flexibility in regard to larger product mixes, smaller series, shorter production runs, and last-minute orders. Often a customer will make a change to their order at short notice, and the raw material’s quality may have changed from when they originally placed their order.

Flexible production lines and planning tools can help you to both predict what to produce and ensure reliable production. You will be able to respond to fluctuations in supplier or customer conditions and raw material flows, depending on the product being made, as well as any demand or schedule changes, all in real time.

By improving agility, you will also increase your factory uptime and yield by minimizing changeovers and enabling flexible scheduling. If you integrate analyzing software into your processing, you can investigate data in real time and make immediate, informed decisions to refine your production systems.

4. Are your products traceable?

Every step of the journey counts: from farm to fork, sea to supermarket. Consumers are demanding reliable information about their food’s origin and production throughout the supply chain. Consumers have a growing desire for information about their food. They want to know all the details of what they are eating: its origin, its nutritional value, and its safety standards. Various degrees of traceability are also required to comply with general food laws and control regulations. The technology to meet these requirements effectively is always improving.

Providing detailed product information may seem impossible for individual products. However, with thorough data collection and advanced software to analyze the data, processors have a strong backbone of food safety information to tackle this challenge. With a traceability engine built into your process, you will be able to record each step of a product’s journey, from source to production, processing, and distribution.

5. Are inaccuracies affecting your throughput level?

Every minute counts when you want to run an optimal production and reduce downtime.

Data can reveal a great number of ‘pains’ in your factory and help you identify opportunities for improvement. With food processing software, you will be able to gather, store, and manage the data generated across the full line and beyond. This will even give you invaluable information such as yield, throughput, capacity, and labor efficiency. Data can also highlight recurring problems with issues like equipment functionality to show which specific area needs attention, which helps you to schedule maintenance proactively.

With the right production data, you will find it easier to identify ways to reduce downtime and increase throughput, which can in turn help you develop new products and processes, thereby opening up new revenue streams.

6. Is ineffective manual handling reducing your yield?

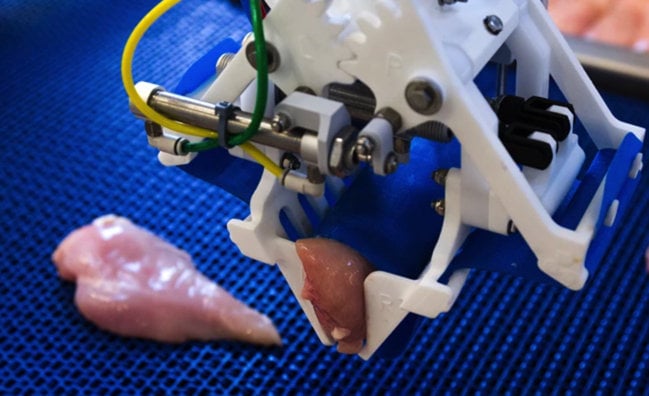

Every deviation counts and even small inaccuracies in your production flow matter. Automating manual processes can make your plant much more productive. Naturally, you want to make the most of every cut, and you want your employees to work in the production line where they create the most value. If your production suffers from inaccuracies or inconsistencies in manual handling, automating processes can help you to reduce labor costs and maintain highest product quality.

One way to optimize your production is to automate some of the manual processes. A dynamic workforce that comprises humans and machines working collaboratively can make your operations significantly more productive. Gradually, automated systems can take over the repetitive and intensive manual operations, and you will only need human interference for process control and adjustment. If you have limited access to skilled workers, automation can also help to fill this gap.

7. Is your production reducing giveaway?

Every gram of meat, poultry, or fish counts if you want to increase yield, have happy customers, and sell products at the most profitable price. Is your production mainly focused on just one premium product, while the remaining parts have to be sold at low prices? When you know how to find the balance between incoming material and customer orders, your operations will have much more added value and your process will become far more sustainable.

From primary processing to deboning systems and portioners, every system can be designed to salvage every last profitable piece of meat, poultry, or fish in the production process. This will help you gain extra grams per product and add value to the offcuts. The key is also to be able to act on any surpluses or shortfalls and utilize a setup that allows you to change processing programs from one product to another. In instances like this, an automated process is much more flexible than a manual one.

What also counts

On our journey to transform the way food is processed, we know that we must make everything count towards more sustainable food production. We want to supply consumers around the world with safe, quality, affordable food, while respecting nature and making its limited resources last.

Making everything count is nothing new. Butchers, Fishermen, and farmers have been working with this mantra since the beginning of time. As feeding, breeding, and preparing involved lots of hard manual work, it was about getting as many edible parts out of the product as possible. Marel has always respected this heritage and we continue to work on the same foundation: all our equipment and solutions mimic the manual operations of yesteryear’s skilled butchers and laborers.

www.marel.com