www.ptreview.co.uk

21

'21

Written on Modified on

Launch of VX 6500G and VX 6500C, Vertical Machining Centers for High-precision Graphite and Ceramic Processing

Doosan Machine Tools (CEO Jae-seop Kim, www.doosanmachinetools.com) has just launched the VX series of vertical machining centers designed for graphite and ceramic processing.

The lineup consists of the VX 6500G, which is optimized for graphite processing, and the VX 6500C, which is optimized for ceramic processing. Equipped with a dual-column structure, the series provides unrivaled processing performance. High-precision processing has been enhanced with the adoption as standard features of a newly developed low-noise, high-precision spindle and a range of peripheral devices in order to deliver the highest level of performance in graphite and ceramic processing.

Designed to Optimize the High-Precision Dual-Column Mechanical Structure

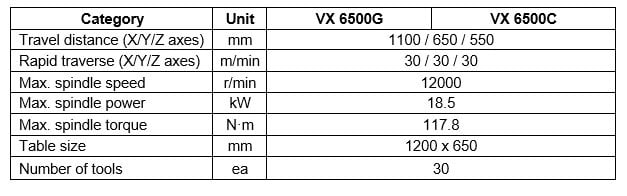

Equipped with a stable, symmetrical, dual-column mechanical structure optimized for high-speed feed and high-precision processing, the VX 6500G (graphic) and the VX 6500C (ceramic) boast a travel distance (X/Y/Z) of 1050/650/550mm and a rapid traverse speed (X/Y/Z) of 30/30/30mm, guaranteeing the optimal processing of graphite/ceramic shapes requiring rigidity, high-speed and high-precision.

Low-noise & Low-vibration Spindle

Thanks to the adoption of a newly developed low-noise, low-vibration spindle, the series has a maximum direct drive spindle speed of 12000 r/min {Option: built-in type 20000, 30000 r/min}, spindle motor output of 18.5 /11kW, and spindle motor torque of 117.8 Nm. Reduced vibration during cutting extends tool life, improves surface roughness, and increases the rigidity required to sustain high-precision performance.

Optimization Package Customized for Machining Characteristics

The series is also equipped with a range of thermal displacement reduction functions - including a ball screw cover, LM guide double wiper, and grease lubrication system - as standard features to deliver performance and convenience optimized for the characteristics of graphite and ceramic processing. Notably, the VX 6500G is equipped with a graphite dust collection system as a standard feature to prevent graphite powder from accumulating in the cabin, while the VX 6500C can process chips efficiently with the addition of a ceramic filter system as an optional feature.

Main Specifications

www.doosanmachinetools.com