Inspection checklists go digital – Siemens and Log.Go.Motion announce partnership

Siemens and Log.Go.Motion - a specialist in the digitalization of processes in industry and logistics - have concluded a cooperation agreement.Effective immediately, Siemens is the exclusive global third-party distributor for the Moby.Check software solution within the process industry. Moby.Check can be used to create, control, and monitor individual digital inspection checklists for servicing and maintenance procedures as well as for production and logistics processes. The software system has been developed for global use in industry.

Moby.Check can be used to create, control, and monitor individual digital inspection checklists for servicing and maintenance measures as well as for production and logistics processes.

- Siemens is the exclusive global sales partner for Moby.Check in the process industry

- Simple functional solution offers advantages for mobile servicing and maintenance procedures as well as for production and logistic operations in the process industry

- Audit-proof storage of testing and maintenance tasks

- Stand-alone solution can be integrated easily into existing maintenance or ERP systems

Siemens and Log.Go.Motion - a specialist in the digitalization of processes in industry and logistics - have concluded a cooperation agreement.Effective immediately, Siemens is the exclusive global third-party distributor for the Moby.Check software solution within the process industry. Moby.Check can be used to create, control, and monitor individual digital inspection checklists for servicing and maintenance procedures as well as for production and logistics processes. The software system has been developed for global use in industry.

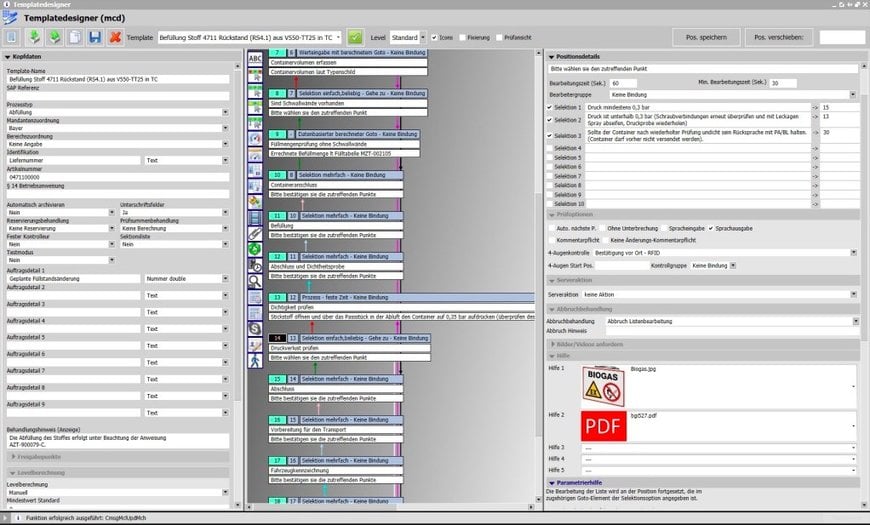

Moby.Check offers simple navigation and a flexible authorization concept. Via a customizable interface on the PC, users can create individual inspection checklists that meet their requirements without programming effort for mobile servicing and maintenance. Templates and interfaces for supplying data for the inspection checklists reduce possible errors and eliminate the effort associated with data acquisition.

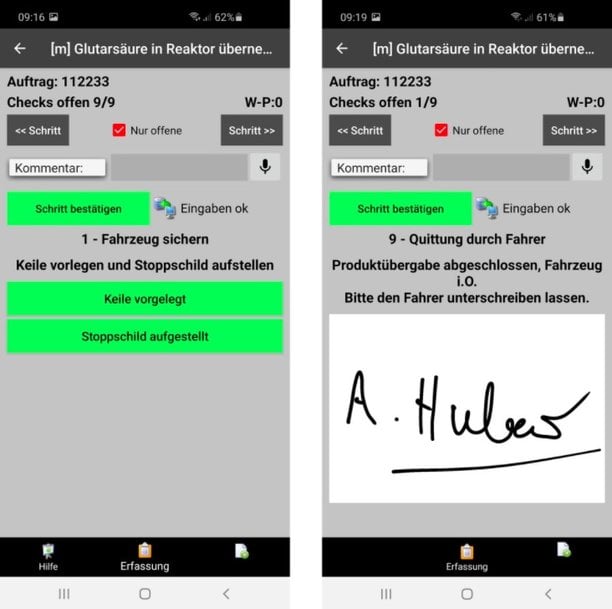

Users can select checking options such as single or multiple selection, input with or without value analysis, free or specified sequence, calculations or branching.

Moby.Check can be used on standard PCs, tablets, and smartphones in the W-LAN and on the mobile network and can be controlled via keyboard and voice. A particular highlight is the option of carrying out two-person monitoring (double check / 4-eyes principle) online with photo and video documentation via tablet or smartphone between the field and the control room. In addition, mobile data communication, scanning, and OCR character recognition save time and prevent input errors. The use of online documentation eliminates the need for copying, filing, and archiving. The results of testing and maintenance work can be transmitted online and transferred via interfaces to ERP, laboratory or PLT systems. It is also possible to use Moby.Check to carry out research and analysis without search processes.

The digitalized processes are executed within companies and documented online.

“We are delighted to announce our partnership with Log.Go.Motion. The Moby.Check function software is another component of the Siemens portfolio that will provide users in the process industry with simple and flexible support for digital transformation. Audit-proof online documentation with image and video evidence also enhances the digital twin,” states Eckard Eberle, CEO Process Automation, Siemens AG.

“This partnership with Siemens means that our innovative Moby.Check software product can be introduced to customers worldwide, with on-site rollout, maintenance, and update services made available in numerous countries. We are combining the advantages of an agile and innovative start-up with the global presence and experience of Siemens in process industry and automation. We are looking forward to further cooperation and successful digitalization projects that will give our customers a competitive edge,” says Dirk Emmerich, CEO Log.Go.Motion GmbH.

www.siemens.com