THE PRECISE GEOMETRY OF 3D CUTTING KBM motors as a byword for accuracy in laser cutting

Pipes for industrial and residential flue ducts are made using machines by KOLLMORGEN Direct Drive motors.

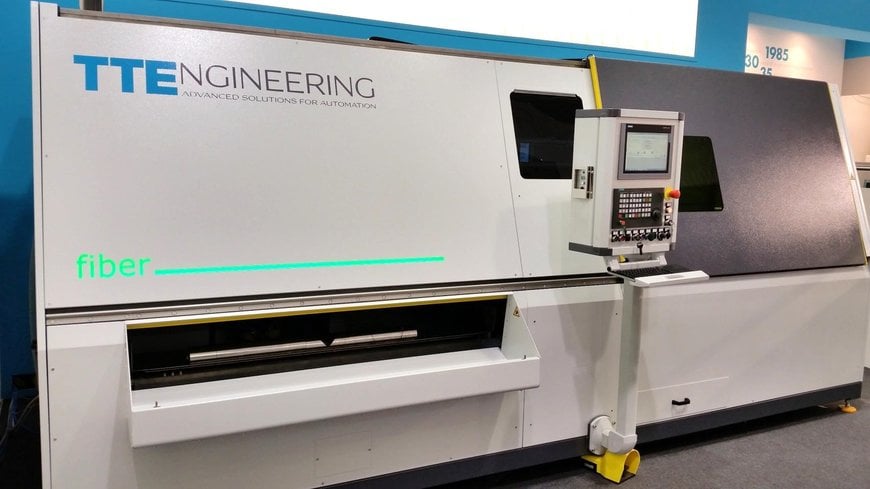

Picture 1 - KOLLMORGEN TTEngineering Cover image

Authors:

Ilario Manzi, Key Account Manager, KOLLMORGEN Italia

Angelo Trombetta, Direct Drive & Mechanical Transmission, KOLLMORGEN Italia

Elisabetta Redaelli, Marketing Communication, KOLLMORGEN Italia

The production of automation systems for sheet metal forming for sectors such as air conditioning, flue ducts and the automotive industry is the core business of TTEngineering. Located in Lomazzo near Como in a modern building of more than 2,000 m2, the company has also gained expertise in the cosmetics, medical, packaging and assembly sectors.

More than 1,500 systems running in factories all over the world and exports accounting for well over 90% of total turnover are sources of pride for the company whose service department is able to respond precisely, quickly and punctually, even remotely.

To meet the ever more pressing needs of the market in terms of delivery time and performance, TTEngineering has concentrated on a design that can satisfy performance requirements in terms of acceleration, precision, productivity and flexibility.

During a meeting in Parma during the SPS trade fair, the Como-based company set out its requirements to KOLLMORGEN. The motion control specialists proposed direct drive technology as the optimal solution for doing away with the complex mechanical transmission that involves drive belts and gear motors. In doing so, TTEngineering embraced the concept of a direct drive motor.

“We see two big advantages with Kollmorgen: it is a global brand that offers design consultancy and after-sales services of a high standard,” explained Massimiliano Crespi, who was Head of Engineering & Production at the time of this particular project and is now Managing Director at TTEngineering “The approach of the Kollmorgen staff during the design phase was outstanding.” The final tests provided the anticipated responses and allowed us to launch the TOP600 onto the market little more than a year later.

TOP600 machine for pipes for flue ducts

The TOP600 is a machine for the 3D cutting of pipes intended for use as flue ducts for all sectors, from industrial to residential, produced with a range of materials.

The TOP600 is a Siemens CNC 5 interpolated axis laser cutting cell suitable for machining pipes with a maximum length of 1,500 mm, with a diameter of between 3” and 30” and thicknesses of 0.4 to 2 mm, made from steel, iron, or copper. The patented pipe clamping system has been created with a CNC self-centering spindle. This machine is aimed at companies operating in the HVAC and chimney pipes sectors. Depending on the combination of materials, thickness, and laser power, it is possible to cut at variable speeds of up to 20 m/min.

It is a modular machine which can be used by one operator who manually loads/unloads the pieces or in “fully automatic” mode, integrated into an automated line where a robot loads/unloads the pieces.

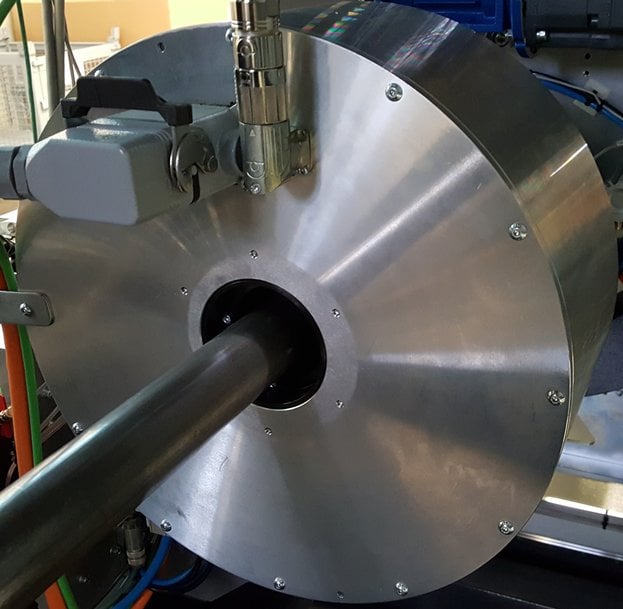

At the same time as updating the direct drive equipment with a torque motor on the rotation spindle, new software has been developed that allows for cutting with beveling.

TTE has its own cad cam platform and sophisticated cutting management software with predictive mathematics to compensate for out of roundness errors: the machine provides perfect cuts even for pieces that are slightly out of gage.

There are two versions available, the TOP600 Plasma and the TOP600 Laser, depending on the cutting technology used. The two machines are identical in terms of their configuration. The only changes are to the source used and, therefore, the type of cutting head used.

KBM Frameless Motors, modern direct drive technology

As an alternative to the technology that has been used in the past, namely precision gear motors and belt drives, KOLLMORGEN recommended a KBM™ series direct drive motor to TTEngineering that can offer greater flexibility and a range of different speeds so the machine can be adaptable and produce pipes with differing diameters.

The design of the machine also benefits, becoming flexible and compact, ensuring stable performance over time, remaining constant even with a high number of cycles (no downgrade).

The KBM™ Series has been developed to be integrated directly into the machine, using its own bearings to support the rotor; it provides a high level of performance whilst allowing for a smaller size. There is a wide range of standard motors (14 sizes with varying lengths); different configurations and options are available depending on the requirement, and changes to the shared design can be made quickly and cost-effectively. “The performance offered by the Kollmorgen KBM™ series motor is so high that they even prompted us to redesign part of the frame and the cutting automation,” explained Mr. Crespi. “The use of the motor also enabled TTEngineering to patent an automated pipe clamping system.”

Properties

• Fully encapsulated stator windings

• PTC thermistor overload protection

• Rare-earth neodymium iron boron magnets

• Fail-safe bands over rotor magnets

• RoHS compliant

• UL and CE certification

• Optimizations include rotor hub dimensions, rotor length, diameter, mounting features, windings, insulation, connection type, and much more

• Optional latching digital Hall effect sensors are pre-aligned and factory-installed

Benefits

• Direct load connection eliminates the need to maintain gearboxes, belts or pulleys

• The absence of backlash and displacement provides a more responsive system

• The removal of coupling devices reduces overall machine size

• Embedded motor enables a compact machine design, helps protect intellectual property

• Huge selection of standard motors and extensive customization options

Conclusion

The profitable collaboration with Kollmorgen continues with a new objective: TTEngineering is working on a product which will replace mechanical cutting with a high-tech laser and Kollmorgen linear motors will again be of great assistance in this case.