ASMPT Expands SMT Analytics with AI-Driven Line Optimization

New Line Balance Analysis and AI reporting boost SMT throughput and transparency.

smt.asmpt.com

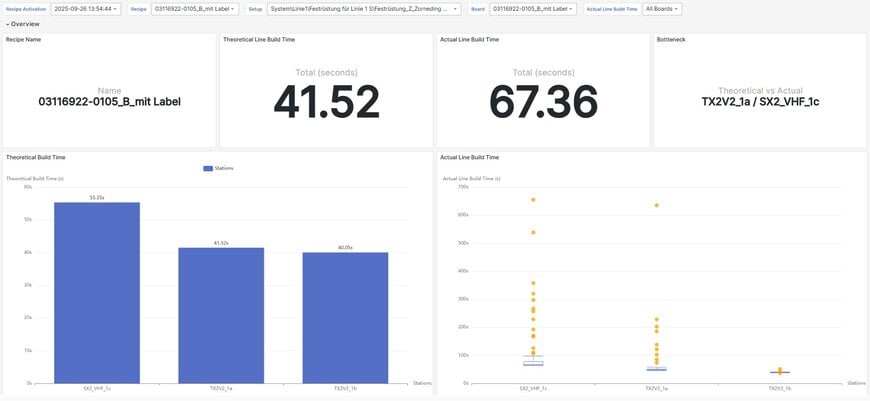

The Theoretical Cycle Time Comparison in SMT Analytics visualizes deviations between current and optimal cycle times in both graphical and tabular form, enabling users to quickly and precisely identify optimization potential.

Image source: ASMPT

ASMPT SMT Solutions has expanded its SMT Analytics software with advanced analytics functions designed to increase production transparency and line throughput in surface-mount technology (SMT) manufacturing.

The latest release introduces Line Balance Analysis, a new capability that enables station-spanning evaluation of time utilization across entire SMT lines. In addition, existing use cases – Theoretical Cycle Time Comparison and Reject Analysis – have been further enhanced to provide deeper operational insights.

Line-Level Transparency and Bottleneck Detection

SMT Analytics consolidates production data from multiple lines and correlates it with theoretically optimal reference values. The objective is to identify bottlenecks, imbalanced line configurations, and hidden optimization potential – even in complex, high-mix manufacturing environments.

The new Line Balance Analysis compares actual product cycle times at each station with reference values calculated by WORKS Programming software. Deviations and throughput-limiting steps are immediately visible, allowing manufacturers to determine which stations constrain performance and how different programs affect overall line balance.

The enhanced Theoretical Cycle Time Comparison now identifies deviations in programming parameters such as waiting times and acceleration settings. Since these parameters influence thousands of placement cycles, even minor adjustments can unlock significant optimization potential.

Cost-Based Reject Analysis and Maintenance Integration

The upgraded Reject Analysis expands beyond reject rates to include component cost-based evaluation. This allows manufacturers to quantify the economic impact of defects more precisely.

Through integration with the Factory Equipment Center, maintenance-related data – including feeder status, cycle counters, and remaining service intervals – is now directly accessible within the analysis environment. This enables data-driven decisions that combine quality, cost, and maintenance performance.

The Line Balance Analysis in SMT Analytics compares the actual cycle times of all stations with their theoretical optimum and makes bottlenecks as well as unbalanced line configurations immediately visible.

Image source: ASMPT

AI-Supported Reporting for Actionable Insights

A major advancement is the introduction of AI-supported reporting. An integrated assistant automatically analyzes production data and delivers structured, prioritized recommendations to improve:

- Line performance

- Component efficiency

- Equipment availability

This reduces the need for manual dashboard interpretation and accelerates corrective action.

SMT Analytics will also support integration of third-party machines via the IPC-2591 Connected Factory Exchange (CFX) protocol, enabling consistent, line-level optimization in heterogeneous production environments.

According to ASMPT, the expanded solution translates deep process expertise into practical, data-driven manufacturing improvements, supporting electronics manufacturers on their path toward intelligent, AI-enabled SMT production.

www.asmpt.com