www.ptreview.co.uk

02

'26

Written on Modified on

Next2OEM: TE Connectivity Drives Automation in Wiring Harness Production

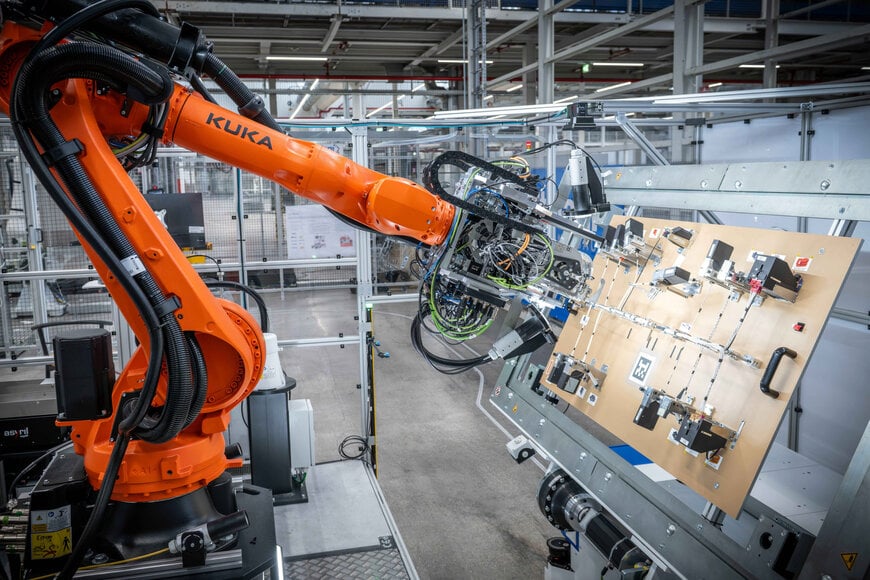

TE Connectivity advances OEM-ready automation by designing wiring harness components for end-to-end robotic assembly.

www.te.com

TE Connectivity, a global leader in connectors and sensors, has played a central role in the recently completed Next2OEM project, funded by the German Federal Ministry for Economic Affairs and Energy (BMWE). As an innovation partner, TE helped push forward the automation of wiring harness production across the entire value chain—from component design and harness manufacturing to automated installation in the vehicle.

Designing for automation from the outset

A key contribution from TE Connectivity lay in the early-stage design of components and mechanical interfaces to ensure stable, repeatable handling by industrial robots. This design-for-automation approach proved essential to achieving reliable integration into an end-to-end automated process flow—especially for traditionally flexible components such as wiring harnesses.

Working alongside an OEM, manufacturing and plant engineering partners, robotics specialists, product data management experts and test-equipment providers, TE demonstrated that robust automation is only possible when components, processes and systems engineering are developed in parallel, with clearly defined mechanical interfaces.

“In the Next2OEM project, we consistently developed our connection technology from the perspective of the automated process chain—not only electrically, but with a strong focus on robotic processing,” said Stefan Glaser, Product Management Director at TE Connectivity. “Market interest confirms that automation-compatible wiring harness components are becoming a strategic enabler for future vehicle platforms—and are now technically feasible.”

Collaboration as a success factor

The project brought together ten companies spanning the full production chain, an unusually broad collaboration that proved critical to meeting the project’s objectives. This coordinated approach enabled the team to validate automated manufacturing and assembly concepts under realistic conditions, laying the groundwork for industrial adoption.

From project outcomes to series production

TE Connectivity will now transfer the results of Next2OEM into series production processes for upcoming vehicle platforms. Insights gained are being applied directly to the development of next-generation contacts and connectors—engineered from the outset for automatic processing.

While the project confirmed the feasibility of automation for many applications, it also highlighted ongoing challenges with highly complex wiring harnesses. To address these, TE is continuing close collaboration with OEMs and technology partners beyond Next2OEM, advancing both incremental improvements and new automation concepts.

Together, these efforts position TE Connectivity at the forefront of OEM-ready, scalable automation for wiring harness production, helping shape the future of vehicle manufacturing.

www.te.com