www.ptreview.co.uk

23

'26

Written on Modified on

Partner Ecosystem for Digital Manufacturing Simulation

Visual Components launches VC Ecosystem to extend platform capabilities through partner-developed add-ons and integrations.

www.visualcomponents.com

Visual Components has introduced the VC Ecosystem, a new section of its website designed to centralize partner add-ons, plugins, and integrations that extend the platform’s simulation capabilities for digital manufacturing environments.

Open platform approach and partner integration

The VC Ecosystem formalizes Visual Components’ strategy of operating an open platform supported by a growing partner network. By curating third-party add-ons in a single, accessible location, the initiative aims to simplify discovery and deployment of complementary tools that address specialized engineering requirements within factory and production system simulation.

This approach reflects increasing demand for modular software architectures in digital manufacturing, where simulation platforms are expected to integrate analysis tools without requiring separate workflows or data transfers.

Ergonomics analysis integrated into simulation

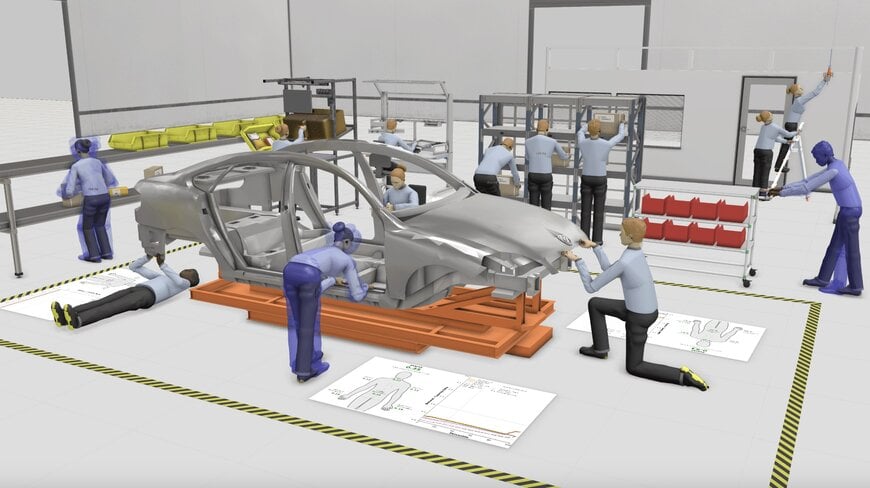

The first add-on featured in the VC Ecosystem is an ergonomics analysis integration developed by Work(s) Ergo Inc.. The integration connects Visual Components’ factory simulation environment with the cloud-based Work(s) ergonomics platform, enabling human-factors analysis directly alongside production models.

Engineers can simulate manual tasks within a factory layout and evaluate worker posture, joint loads, and musculoskeletal risk without leaving the simulation environment. This supports earlier assessment of human performance constraints during system design, rather than after physical implementation.

Data exchange and analytical workflow

Through the integration, posture and task data generated in Visual Components are exported to the Work(s) service for detailed ergonomics evaluation. The results are then visualized within the simulation context, allowing users to interpret ergonomics metrics alongside 3D models of workstations and material flows.

Analytical outputs include posture assessments, joint load demands, and aggregated risk scores. The Work(s) platform evaluates thousands of feasible worker postures to account for variability in body size and movement, supporting more representative assessment of manual operations.

Scientific basis and assessment methods

The ergonomics analysis is based on validated scientific models commonly used in human factors engineering. These include methods such as HandPak™, the Arm Force Field (AFF), and the Liberty Mutual Manual Materials Handling equations. By grounding the analysis in established research, the integration provides traceable and reproducible results suitable for engineering decision-making.

The add-on supports a range of manual material handling activities, including lifting, lowering, pushing, pulling, carrying, and static postures, which are common sources of ergonomic risk in manufacturing and logistics environments.

Application context

By combining factory simulation with integrated human-factors analysis, the VC Ecosystem and its initial ergonomics add-on address a gap between production system design and occupational risk assessment. This integration enables engineers to evaluate productivity, layout efficiency, and ergonomics within a single digital manufacturing workflow, supporting more informed design decisions early in the development process.

www.visualcomponents.com