www.ptreview.co.uk

22

'26

Written on Modified on

Automatic Servo Axis Tuning via Integrated Software

SIGMATEK extends LASAL with automated controller optimization for the MDD 2000 servo drive to reduce commissioning time and improve control quality.

www.sigmatek-automation.com

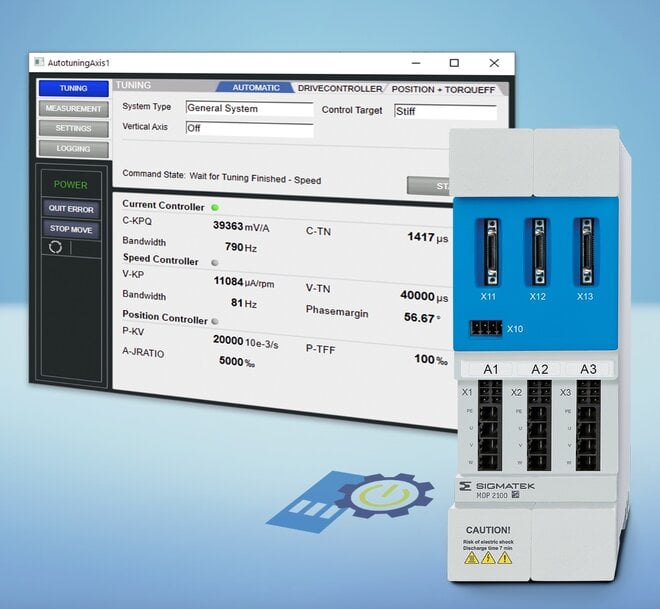

SIGMATEK has enhanced its LASAL engineering software with an auto-tuning function that automates the commissioning of servo axes for the MDD 2000, replacing manual controller parameterization with algorithm-based optimization.

Automated commissioning of servo axes

Commissioning servo drives typically requires iterative adjustment of current, speed, and position controllers, often involving repeated test cycles and manual fine-tuning. The new auto-tuning function in LASAL addresses this by automating the complete parameterization process for servo axes connected to the MDD 2000.

The optimization process is initiated via software and executed without manual intervention, significantly reducing setup time during machine commissioning. This is particularly relevant for machine builders working with multi-axis systems, where commissioning effort scales with the number of drives.

End-to-end controller optimization

Parameterization is fully automated across the entire control chain. This includes the current controller, speed controller, position controller, and torque feedforward control. Measurement data required for tuning is recorded directly by the MDD 2000 servo drive, while the programmable logic controller (PLC) performs the mathematical evaluation.

The evaluation process includes Discrete Fourier Transforms (DFT) and the calculation of Bode diagrams using Sweep Frequency Response Analysis (SFRA). Based on these results, controller parameters are set, optimized, and validated against defined performance criteria. This closed-loop approach ensures that tuning is not limited to static parameter calculation but includes verification of control behavior.

User interaction and visualization

For the user, auto-tuning is accessed via a visualization object (VOV) within LASAL. The operator selects the control loop to be optimized, defines the tuning range, and starts the automated procedure. Once initiated, the algorithm performs the tuning sequence independently, eliminating the need for manual re-adjustments or expert intervention during the process.

This software-based interaction supports reproducible results and reduces the risk of configuration errors that can occur during manual tuning.

Synchronous tuning of multiple axes

In machines with coordinated motion, multiple servo axes often need to be tuned in parallel to ensure consistent dynamic behavior. A higher-level class within LASAL CLASS enables synchronous tuning of several axes by coordinating their start, measurement cycles, and parameter updates.

All involved drives perform measurements simultaneously and receive the optimized parameters as a group. This approach supports consistent control behavior across axes and simplifies commissioning in complex motion systems.

Application context

The auto-tuning function is designed for use in industrial automation and motion control applications where commissioning speed, control quality, and repeatability are critical. By integrating measurement, analysis, and parameter optimization into the engineering software, SIGMATEK provides a method to accelerate machine readiness while reducing the likelihood of operating errors during setup.

www.sigmatek-automation.com