www.ptreview.co.uk

21

'26

Written on Modified on

Digital Engineering Integration for Smart Weaving Platforms

Siemens software enables digital transformation for smart weaving platforms, optimizing performance and strengthening the digital thread across Picanol Group.

www.sw.siemens.com

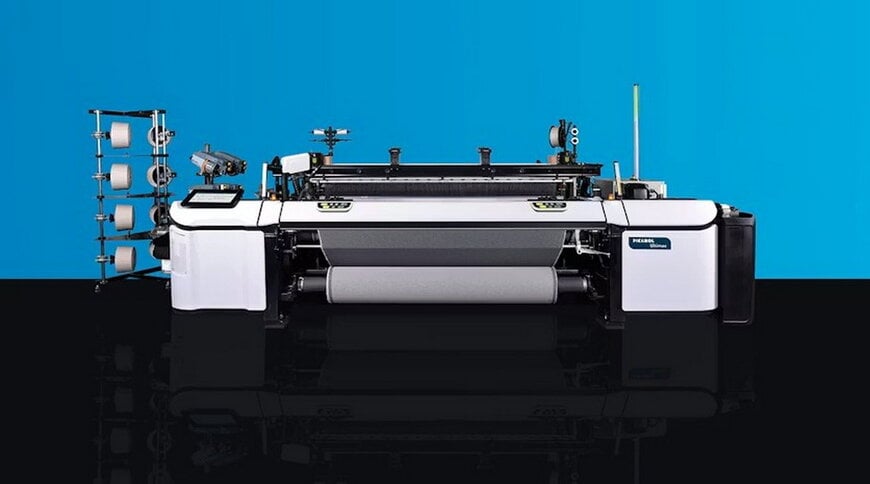

Picanol, a Belgian manufacturer with more than eight decades of experience in high-tech weaving machinery, is deploying the Siemens Xcelerator software portfolio to modernize and accelerate its engineering and production processes. The collaboration targets reduced product development cycles, enhanced handling of complex configurations, and tighter integration across enterprise systems. This initiative reflects broader industry trends in digital transformation, where manufacturers adopt integrated digital platforms to maintain competitiveness, improve sustainability, and accelerate innovation.

Digital Thread and Engineering Integration

Picanol selected Siemens Xcelerator for its capability to unify multiple aspects of product engineering and lifecycle management within a coherent digital framework. At the core of the implementation is Siemens’ Designcenter NX software, which Picanol uses for advanced product engineering. This is complemented by Teamcenter, Siemens’ product lifecycle management (PLM) solution, which provides structured workflows and a “digital thread” linking product data, design revisions, and development activities. Leveraging these tools allows Picanol to reduce the prevalence of bespoke customizations, adopt standardized engineering processes, and facilitate connections to enterprise resource planning (ERP) and manufacturing execution systems (MES).

Digital twin technology, enabled through Siemens’ Simcenter software, plays a central role in virtual performance validation. By simulating machine operation before physical construction, Picanol can optimize designs for energy efficiency and operational performance, reducing physical prototyping and resource consumption. This simulation-led engineering supports both sustainability goals and accelerated time-to-market for next-generation machines.

Strengthening Collaboration and the Digital Thread Across Divisions

Beyond core engineering functions, the adoption of Siemens Xcelerator extends to Psicontrol, part of the Picanol Group, for controller hardware and software development. Implementing Teamcenter as a unified collaboration platform strengthens cross-disciplinary coordination and ensures that hardware and software development benefit from the same foundational digital infrastructure. This alignment of development environments across divisions reduces friction in product integration and supports more consistent product quality and delivery.

Differentiation and Competitive Positioning

The use of Siemens Xcelerator distinguishes Picanol from competitors that may rely on fragmented or siloed development systems. Instead of managing isolated CAD, PLM, and simulation tools with limited interoperability, Picanol has adopted an integrated suite that fosters a continuous digital thread from initial design through manufacturing. This approach supports faster iteration cycles, improved transparency across development stages, and greater adaptability to customer-specific configurations—an important competitive factor in markets where highly configurable machinery is the norm.

In contrast to traditional engineering environments where customizations can slow processes and introduce errors, the standardized workflows and connectivity enabled by Siemens Xcelerator help Picanol reduce unnecessary complexity. The inclusion of digital twin technology further differentiates Picanol’s engineering processes by enabling extensive virtual validation, which can mitigate risks and decrease the need for costly physical prototypes.

Implications for Industry Digitalization

Picanol’s adoption of a comprehensive digital platform mirrors a broader shift in manufacturing toward integrated digital ecosystems that span design, engineering, production, and business systems. Platforms like Siemens Xcelerator are positioned as end-to-end solutions that enable companies to align operational technology (OT) and information technology (IT), extend digital twin capabilities, and incorporate simulation and analytics into routine workflows. Such platforms also support ecosystem interoperability with third-party tools and services—facilitating collaboration with suppliers, partners, and customers.

By embedding these capabilities into its product development processes, Picanol enhances its ability to innovate rapidly and consistently deliver machines that meet evolving customer requirements. Increasingly, these capabilities are expected to form a baseline competitive expectation in sectors where digital transformation drives productivity, sustainability, and quality outcomes.

Picanol’s deployment of Siemens Xcelerator reflects a strategic digital transformation aimed at unifying engineering disciplines, streamlining product lifecycle processes, and enabling advanced simulation-driven design. The initiative positions Picanol to manage complexity more effectively and differentiate its offerings in a competitive marketplace, while aligning with broader industrial trends toward integrated digital platforms that support end-to-end product development and operational efficiency.

www.siemens.com