www.ptreview.co.uk

16

'26

Written on Modified on

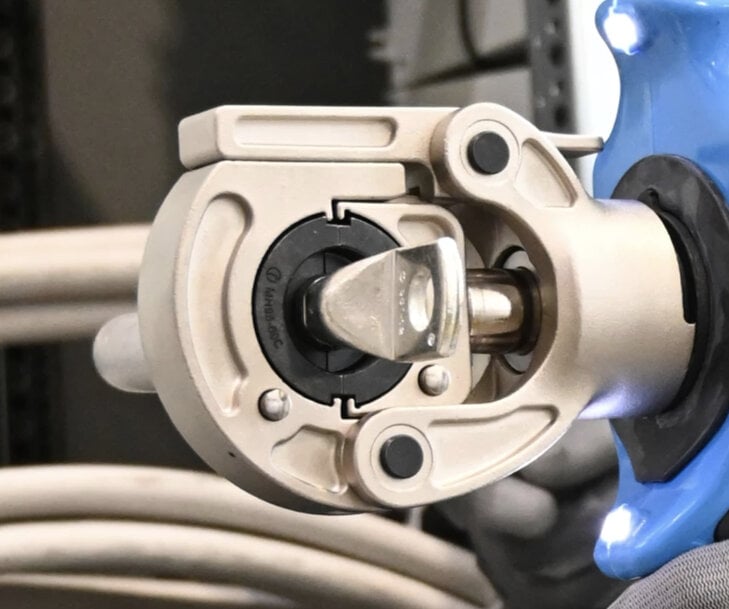

Cembre introduces BA600C adaptive cordless crimping tool

Cembre launches the BA600C, a battery-powered hydraulic crimping tool with adaptive force control, designed to improve precision, safety and service life in electrical connector installation.

www.cembre.com

Efficient and reliable electrical connections depend on precise crimping force, correct connector positioning and consistent tool performance. With the BA600C, Cembre introduces a cordless hydraulic crimping tool that combines hydraulic power with adaptive control logic to optimise crimp quality while reducing mechanical stress and energy consumption.

The BA600C is designed for crimping electrical connectors on conductors up to 300 mm² (600 MCM AWG). It operates with 60 kN (6.1 tonnes) Cembre dies and supports a wide range of connector sizes, targeting professional electrical installation and industrial applications where repeatable, compliant connections are required.

Adaptive force control for connector-specific crimping

A central feature of the BA600C is its adaptive control function. Instead of applying maximum hydraulic pressure for every crimping cycle, the tool automatically adjusts the applied force based on the connector cross-section.

Crimping stops as soon as the dies reach the mechanical stop point, ensuring that only the force actually required for the specific connector is applied. This avoids repeatedly reaching the system’s maximum pressure of 700 bar, reducing wear on internal components and lowering overall energy consumption. The adaptive function can be activated or deactivated by the operator depending on the task and installation requirements.

Hold function for accurate positioning

To support correct installation and alignment, the BA600C includes a hold function that assists with positioning before crimping. When a connector is inserted into the crimping head, the tool detects the first resistance and automatically halts die movement without performing the crimp.

This allows the operator to check that the connector is correctly positioned between the dies and to align the conductor precisely within the terminal. By preventing premature crimping, the function reduces the risk of installation errors and non-compliant electrical connections.

Adaptive service and extended maintenance intervals

The BA600C introduces an adaptive service concept that links maintenance intervals to actual tool usage. In standard operation, the service interval is defined at 30,000 cycles. When the adaptive function is enabled, the tool recalculates service consumption based on the pressure reached during each cycle.

For medium cross-section connectors, this approach can extend the service interval to up to 100,000 cycles, as only a fraction of full-pressure usage is accumulated per operation. This reduces downtime and supports more efficient maintenance planning in high-volume installation environments.

Operator interface and safety features

A redesigned OLED display provides clear, real-time visibility of essential operating parameters, including developed pressure, battery charge status, total work cycles and remaining cycles until maintenance is required. This information supports both day-to-day operation and preventive maintenance planning.

For improved operational safety, the BA600C is equipped with a double-click activation system that prevents accidental start-up. The tool also automatically switches off after three minutes of inactivity, reducing energy consumption and minimising the risk of unintended operation.

With its combination of adaptive force control, precision positioning support and extended service intervals, the BA600C reflects a shift toward more intelligent, application-aware crimping tools for modern electrical installation and industrial use.

www.cembre.com