www.ptreview.co.uk

24

'25

Written on Modified on

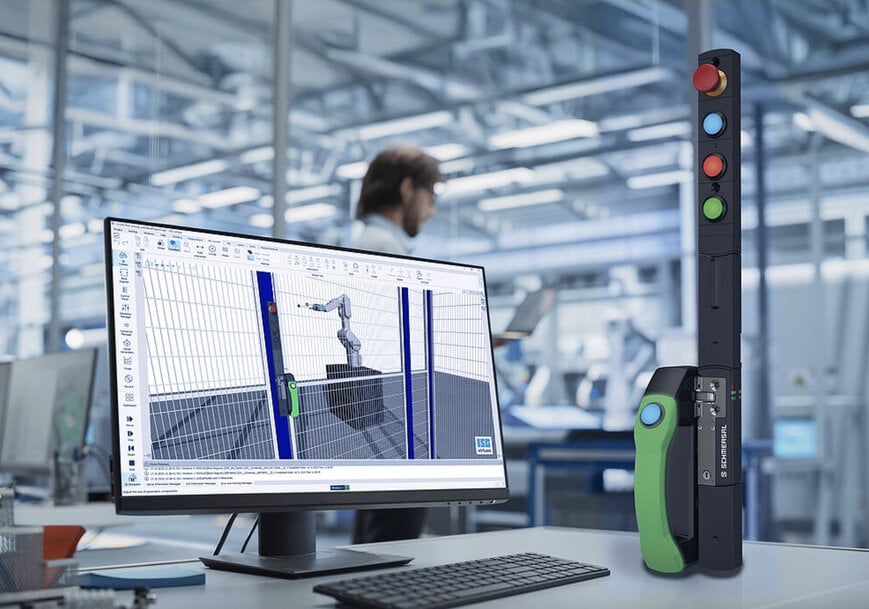

Schmersal Introduces Advanced 4D Digital Twins for Machine Safety

New 4D models enable realistic behaviour simulation, early error detection, FMU-based integration, and virtual commissioning with real control systems for efficient development.

www.schmersal.com

Why 4D Safety-Component Models Matter in Machine Design and Automation

In machine building, industrial automation, robotics and systems engineering, virtual planning tools are becoming essential for reducing development time and improving system reliability. A common question from engineers and integrators is how realistic digital twins of safety components can enhance virtual commissioning. Schmersal’s new 4D models provide a concrete answer by combining precise geometry with real behavioural simulation—setting them apart from typical 3D or static models available on the market.

What Makes Schmersal’s 4D Models Different?

Schmersal has introduced advanced 4D digital twins for key safety-related components, including the AZM40 solenoid interlock, the DHS door handle system and the BDF40 control panel. Unlike conventional 3D models that only represent shape and dimensions, these 4D models reproduce both geometry and real operational behaviour. They digitally mimic how components interact in live machine environments, enabling the simulation of signal flows, control sequences and safety logic as they would occur on physical equipment.

By reflecting full operational functionality, the models support end-to-end virtual machine processes that closely match real commissioning conditions—an area where many competing digital models still rely on simplified or static behaviours.

How 4D Models Improve Virtual Commissioning Efficiency

The main advantage of Schmersal’s 4D models is the ability to perform virtual commissioning long before hardware is installed. Development teams can detect configuration errors earlier, streamline design cycles and significantly reduce on-site testing time.

An additional differentiator is the native compatibility with real control systems from suppliers such as Beckhoff and Siemens. The models can be connected to actual PLC programs to test system settings and logic before installation. This creates a realistic validation environment that exceeds what is typically possible with basic CAD files or limited-function simulation models.

Why FMU Integration Matters for Scalability

Schmersal supports Functional Mock-up Units (FMUs), enabling standardised integration into a wide range of simulation platforms including Siemens Simit, ISG-virtuos and 3DEXPERIENCE. FMU support ensures interchangeability, long-term reusability and easier scaling—key capabilities that many proprietary digital-twin solutions still lack.

The AZM40 is the first device for which the FMU version is already implemented, demonstrating the company’s intention to make behavioural modelling widely accessible.

Growing Access Through TwinStore

The AZM40 4D model is also the first Schmersal product available in TwinStore, a dedicated online marketplace for ready-to-use 4D simulation models. Its publication marks the beginning of a broader digital expansion, with additional components to follow. This approach provides engineers with immediate access to validated, plug-and-play digital twins, reinforcing Schmersal’s position as an early mover in realistic safety-component modelling.

Conclusion: How Schmersal Stands Out in Digital Machine Engineering

For professionals exploring digital twins for automation and safety systems, Schmersal’s 4D models offer a level of behavioural realism and simulation compatibility that goes beyond standard 3D files. The combination of functional behaviour, FMU portability, virtual commissioning support and availability through a dedicated marketplace positions the company ahead of competitors who mainly provide static or limited-function representations.

As virtual engineering continues to grow, these 4D digital twins provide a more accurate, scalable and efficient way for machine builders to design, test and validate safety-critical systems before they reach the production floor.

www.schmersal.com