HBK Advances Robotics with Custom High-Precision 6-DoF Sensors

HBK delivers customised 6-DoF force/torque sensors with real-time precision, durability and OEM-focused co-engineering to enhance robotic tactile intelligence and adaptive automation.

www.hbkworld.com

With decades of precision measurement expertise, HBK is helping robots “feel” and interact with their environment safely and intelligently.

We spoke to Ryan Young, Global Head of Engineering - OEM Sensors, who heads up development of customised 6-DoF force/torque sensors for OEMs to find out more.

Why have 6-DoF force/torque sensors become essential in modern robotics?

Robots can no longer rely solely on vision or pre-programmed trajectories. They need to sense and adapt in real time. A 6-DoF sensor can simultaneously measure three forces and three torques, giving robots a true sense of touch. This physical intelligence is critical for collaborative robots, adaptive logistics, and even surgical robotics.

What makes HBK’s technology different from other solutions on the market?

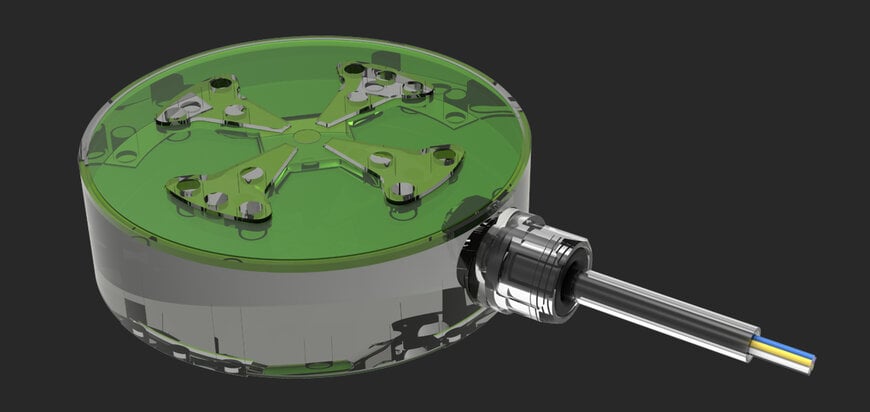

Precision is in HBK’s DNA. We rely on high-sensitivity strain gauges, combined with our proprietary calibration methods. The result is sub-millisecond latency, <1% crosstalk, and durability proven over millions of load cycles. Many sensors are 'components'; HBK delivers industrial-grade, fully calibrated solutions ready to integrate into demanding environments.

How do you collaborate with OEMs on customised sensor design?

It’s a co-engineering process; we start by analysing OEM requirements - mechanical geometry, payload, environment and communication protocol. Then we adapt the sensor design - form factor, embedded electronics and software interface. Finally, we validate it in real operating conditions. The key is delivering a sensor that fits seamlessly into the robot, without compromising on accuracy, robustness, or size.

What are the main technical challenges in customising 6-DoF sensors?

These three are particularly notable:

- Minimising crosstalk, even when it’s under combined loads.

- Ensuring ultra-fast responsiveness for high-frequency picking and assembly.

- Balancing compactness with robustness, as sensors in logistics or medical robotics must be small, yet resilient to demanding environments.

Every project is a balance between these factors - our engineering experience is what makes it possible.

What is your approach to helping logistics companies accomplish automation goals or optimise their existing robotic solutions?

Our approach is always partnership-driven. Logistics is a fast-moving sector with unique challenges - high throughput, mixed item handling, and the need for absolute reliability. We start by understanding the company’s automation goals, whether it’s reducing damage rates, improving picking speed, or enhancing human–robot collaboration.

Then we tailor the 6-DoF sensor design to fit their robotic platform, validate it under real warehouse conditions, and fine-tune the integration with their control systems. The key is that HBK does not deliver a “one-size-fits-all” sensor - we deliver customised solutions that optimise robotic performance. This is why leading logistics providers trust us: we help them achieve measurable results such as higher efficiency, safer operations, and better ROI on their automation investments.

Which industries benefit most from HBK’s 6-DoF sensors today?

Collaborative robotics in manufacturing and logistics are leading the way. But we also see strong momentum in medical robotics for minimally invasive surgery - and in autonomous mobile robots (AMRs/AGVs) for precise docking and payload handling. Each industry brings unique requirements, which drives innovation in our designs.

How do you see 6-DoF sensing technology evolving in logistics and automation over the next five years?

We’re heading towards sensor fusion. Vision, AI, and tactile sensing will converge. Robots won’t just follow a plan; they’ll make decisions based on what they 'see' and what they 'feel.' At HBK, we’re focusing on miniaturisation, AI-enhanced calibration, and standardised interfaces so sensors become plug-and-play for OEMs.

If you had to summarise HBK’s value for OEMs in one sentence?

With HBK, a robot doesn’t just move - it understands its physical interactions, becoming safer, smarter, and more adaptable.

The emergence of physical intelligence is reshaping robotics and automation. With its customised 6-DoF sensor technology, HBK enables robots that don’t just move — they understand their interactions.

www.hbkworld.com