www.ptreview.co.uk

22

'25

Written on Modified on

Less engineering effort, more efficiency

Digital Engineering Service from Schmalz allows users to save up to 80 percent of engineering time and achieve their goals effortlessly.

www.schmalz.com

Digital Engineering Service from Schmalz – Engineering process simply automated: The web-based Digital Engineering Service from Schmalz designs tailored gripping solutions for any number of different sheet metal parts digitally and automatically. This allows users to save up to 80 percent of engineering time and achieve their goals effortlessly.

Design engineers are familiar with the problem, for example with workpieces in a 2D laser cutting application: They have to check where the optimum gripping points are for each sheet metal part, which gripper is suitable and how to control the suction cups. The new Digital Engineering Service has already proven its worth in a exemplary customer analysis. With just 30 sheet metal parts, the working time in designing the gripping solution was reduced from five days to one day. These savings even increase with increasing sheet metal part diversity.

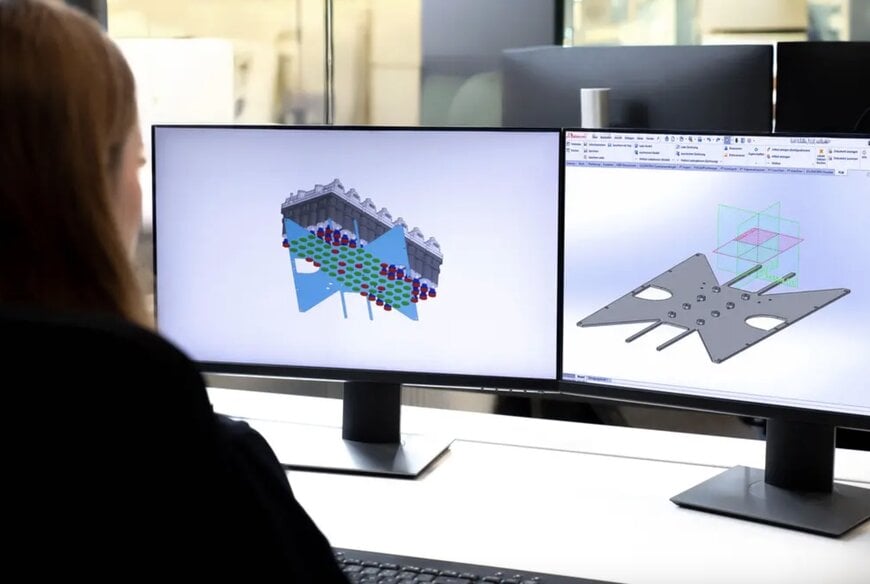

The tool works as a pure web service; users do not need to install any software. They simply call up the website, upload their CAD data and start the analysis. The system supports all common CAD formats such as DXF, STEP or X_T. It even automatically converts curved sheet metal parts into 2D data. If you do not have CAD models, you can generate the data using a selection mask and the individual dimensions.

Millions of gripping points calculated in seconds

When dealing with quantities between ten and twenty workpieces, manual gripper design quickly becomes confusing. For 100 or more workpieces, no designer can keep track of all variants and calculate the optimal gripping points. This is where the Digital Engineering Service shows its strength. The technology is based on the Finite Element Method (FEM), a mathematical process for structural analysis. The system identifies around one million possible gripping points per workpiece. It evaluates which configuration achieves the highest coverage and best fits all the different workpieces. Afterwards, it suggests three variants and recommends the best gripping solution.

From upload to result

The percentage of workpieces that can be handled with the gripping solution is displayed – it's not always possible to handle all parts with just one gripping solution. An example: If you mainly process 20 by 20 centimeter sheet metal parts, but move two-meter-long parts twice a day, you will need different systems for each. The new Schmalz service identifies such cases and shows which sheet metal parts the optimized gripper cannot handle.

The user can see the gripping points that the system has set for each workpiece. The analysis PDF also provides information on the coverage achieved for each part, whether there are deviations from the standard and and if any individual parts are critical. A video sequence visualizes the results. With just a few clicks, a reliable design of a solution tailored to the specific workpieces can be created. The result can then be conveniently downloaded or requested directly as a gripping solution. The technical sales team checks whether the solution is suitable for the requested application.

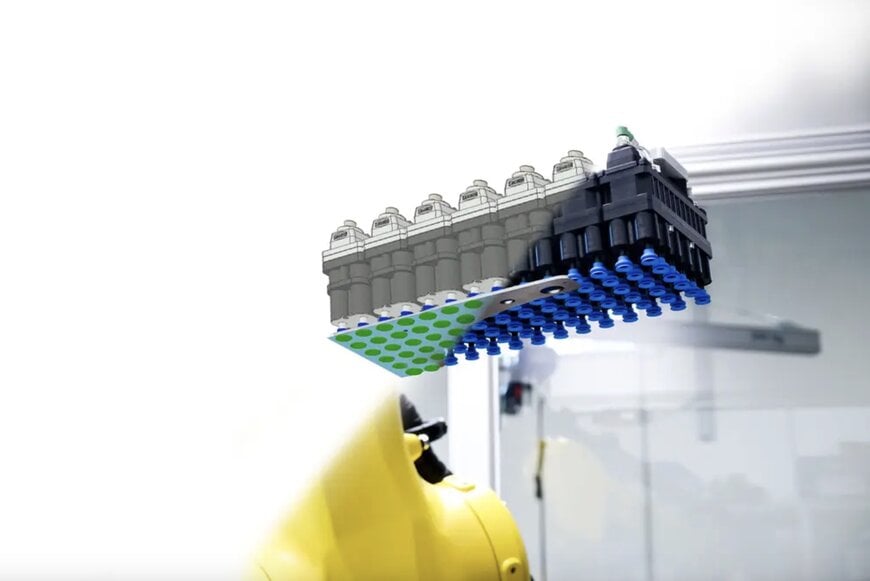

The matrix area gripper FMG as the heart of the system

The matrix area gripper FMG is particularly suitable for handling differently shaped sheet metal parts. It is modularly expandable and can be configured in many variants. The Digital Engineering Service selects the right components for the specific use case from this modular system. The suction cups can be controlled individually and therefore allow individual area grippers to be built with maximum flexibility. Because the suction cups only extend where they are actually needed, the system operates without misgrips and saves energy. Inactive areas are sealed, and the air saving function keeps consumption low. Even in the event of a power failure, the workpiece remains securely held. The matrix area gripper FMG is particularly impressive in combination with the Digital Engineering Service – together, the full power is unleashed in high-mix, low-volume processes in sheet metal processing, for example when loading and unloading laser, continuous and bending machines.

Areas of application: Special machine construction and system integrators

Especially machine builders and system integrators benefit from the new Digital Engineering Service. It allows the right gripper to be designed simply and in line with requirements – for a cost- and energy-efficient, sustainable solution. An individually configured system is not oversized, but focuses on the core functionalities that are actually required.

If the parts portfolio changes during the machine life cycle, Schmalz recommends a new analysis. The service then checks whether the existing gripping solution is still suitable for the new workpieces or whether a different system would work more efficiently and thus reduce costs. All calculations run on servers in Germany. The General Conditions of Sale regulate the GDPR-compliant handling of CAD data.

80 percent time and 2,500 euros in cost savings

For an application involving, for example, 30 different parts, the service reduces the engineering time by at least 80 percent. Manual design takes about a week, while the automated process completes it in less than a day. Schmalz estimates a cost saving of around 2,500 euros for this project, based on typical hourly rates in design engineering.

The system currently works with 2D sheet metal parts in any dimensions. When CAD data is uploaded or dimensions are entered, an automatic suitability check of the submitted data takes place. This check primarily focuses on the quality of the CAD data and the compatibility of the file format. The tool is growing dynamically and Schmalz is successively expanding the parameters.

Innovation leader Schmalz offers the service free of charge. This saves customers a lot of design work and the hassle of searching through product catalogs. The solution complements the vacuum specialist’s focus on optimization: system integrators and machine builders receive a service that allows them to easily perfect their systems themselves—energy-efficiently and sustainably.