www.ptreview.co.uk

17

'25

Written on Modified on

SICK AT SPS 2025: A PARTNER FOR INTELLIGENT AUTOMATION

Topics that will be covered include image-based quality control, automation of autonomous vehicles and robots, precision measurement technology, material flow digitalization and scalable, digital IIoT platforms.

www.sick.com

Photo: SICK

At the Smart Production Solutions SPS 2025 trade fair set to be held from November 25-27, 2025, in Nuremberg, SICK (Hall 7A, Stand 340) – a holistic partner for automation solutions – will be showcasing its future-proof cybersecurity and service offerings. Under the motto "We create value together", visitors to the trade fair stand will learn how sensor data can analyze and optimize production and logistics processes in practical and application-oriented settings. Topics that will be covered include image-based quality control, automation of autonomous vehicles and robots, precision measurement technology, material flow digitalization and scalable, digital IIoT platforms. The consideration of increasingly important cybersecurity requirements and service offerings is an integral part of applications for sensor and system solutions.

As one of the most important international trade fairs, the annual SPS fair covers the entire spectrum of smart and digital automation solutions – from simple sensors to intelligent solutions, from the latest version of technology to the opportunities that are set to arise in the increasingly digitalized industries of the future. “As an automation partner that takes a holistic approach to the unique industrial environments of our customers, the SPS is the ideal platform to showcase our strength in intelligent automation and our cross-industry, innovative solution expertise to a broad specialist audience," says Tobias Güttler, Head of Marketing & Technology Competence Center at SICK Vertriebs-GmbH in Düsseldorf. “Visitors to our stand will be given an insight into our world in a friendly and informal setting, with advice and information being simply and conveniently targeted to their respective requirements.”

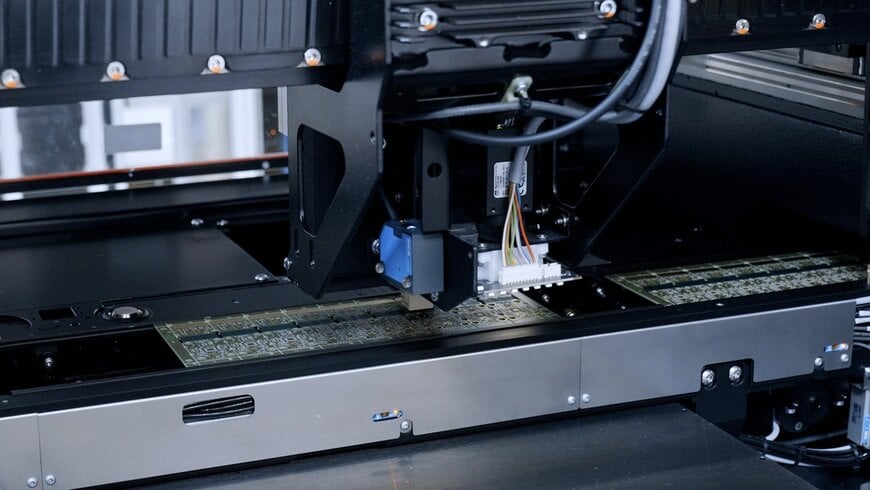

Image-based quality control

With its SICK Nova image processing platform, the company will demonstrate how vision solutions can be used to implement efficient quality control in consumer-related industries such as food and packaging technology. It is available for various 2D and 3D vision sensors from SICK, such as the InspectorP, Visionary, picoCam2 and midiCam2 product families with SIM (Sensor Integration Machine) or Ruler in the form of hardware-specific SensorApps. As a software basis with intuitive UX design and AI-supported Deep Learning, SICK NOVA makes it possible to simply and easily implement demanding applications for presence monitoring, quality control, and intelligent inspection, even without specialist knowledge.

Photo: SICK

Industrial robotics

With the PLB robot guidance system, SICK will present its innovative solution for flexible 3D part localization for the automated picking of objects from pallets or containers. With the help of 3D cameras, powerful software algorithms and artificial intelligence, PLB-guided robots can locate and grip randomly arranged small parts in a container just as reliably as it can grip boxes, assemblies or cast parts on a pallet or special load carrier. The software of the pre-calibrated 3D camera systems and the functions of the PLB can be easily integrated into the control of industrial robots in just a few minutes. Thanks to the Deep Learning function, the 3D camera systems are capable of learning, thus increasing the flexibility of use in changing bin-picking applications. The software's user interface can be easily configured and customized. Bin-picking applications can thus be implemented even more flexibly, efficiently and reliably.

Photo: SICK

Automation of autonomous vehicles

Intelligent collision avoidance and area monitoring with robust 3D image processing – this is what the VISIONARY AI Assist driver assistance system, set to be presented for the first time at SPS 2025, stands for. It consists of a smart Visionary-B Two 3D snapshot camera and the AI Assist software. Developed for harsh outdoor conditions, the measuring stereo camera system with 3D environmental perception capability warns of critical situations in the working area of mobile machines. AI Assist supplements route, side and rear area protection with the option of targeted person detection. This enables reliable and differentiated detection for prioritized warnings. VISIONARY AI Assist is an all-in-one solution – because the data processing and AI software are also fully integrated into the monitoring system, which can be configured using a web browser.

Photo: SICK

Material tracking in material flow

In both non-automated and semi-automated areas, detailed positions and movements of materials on load carriers and industrial trucks are used to keep track of all relevant material flow information. These help to evaluate and control the flow of goods. To ensure transparency and traceability in internal supply chains, SICK has a complete portfolio of identification and localization solutions. These are used at various points in the material flow. This means they cover the entire goods flow process – from goods receipt, storage and picking through to goods issue and dispatch. This guarantees complete control and transparency of the goods supply as well as facilitating optimized transport routes and minimized search times.

For example, the Ident Gate System uses a wide range of sensors to identify palletized goods that are marked with bar codes or 2D codes or with UHF RFID or hybrid tags. Seamless IT integration in the merchandise management system rounds off the concept. The Automated Load Detect Ident System (ALDIS) ensures the localization of forklift transport operations on the factory premises. It creates transparency and helps to simplify the growing complexity of intralogistics processes, while also facilitating accurate, flexible and cost-efficient localization and identification of goods. Intelligent sensors automatically detect loading and unloading processes of industrial trucks. The transport materials are automatically identified via bar codes, 2D codes or RFID. The combination of ultra-wideband (UWB) and GPS technology enables the global tracking of goods to their final site of deployment.

Photo: SICK

Scalable digital solutions

Scalable digital applications have become an integral part of today's industrial world. To provide its customers with even better support in the digitalization of processes and applications, SICK has developed an end-to-end and scalable IIOT platform. It combines efficient engineering, seamless OT-IT integration and data-based optimization. Engineering and programming tools help with application design, commissioning, maintenance and the entire life cycle management of the devices. In addition, data streams can be integrated securely, continuously and efficiently with solutions from SICK. They support a wide range of industrial fieldbuses and interface technologies. The application-specific solutions collect, analyze and visualize data from various sources. This allows data-based processes, such as machine availability or transparency in the material flow, to be optimized. The end-to-end approach across the entire life cycle reduces the complexity of digitalization processes. And thanks to the modular structure of the IIoT platform, the solutions adapt to individual challenges and can also be scaled for future tasks.

With the OD200, SICK will also present a measuring detection and distance sensor for short scanning ranges in a miniature design that can be used for such a data source. The sensor sets a new standard in its class with unprecedented measurement stability on highly reflective, black and irregular surfaces. With a newly developed measuring core with a high-resolution receiver line and an optimized optical system, the new distance sensor achieves a level of precision, linearity and repeatability that is otherwise only offered by high-end devices. As a result, the OD200 ensures high measured value stability and reliable, reproducible detection and switching behavior. This makes the distance sensor a convincing solution for a wide range of applications in various industries, including the automotive sector, consumer goods, electronics, mechanical and plant engineering.

At the Smart Production Solutions SPS 2025 trade fair set to be held from November 25-27, 2025, in Nuremberg, SICK (Hall 7A, Stand 340) – a holistic partner for automation solutions – will be showcasing its future-proof cybersecurity and service offerings. Under the motto "We create value together", visitors to the trade fair stand will learn how sensor data can analyze and optimize production and logistics processes in practical and application-oriented settings. Topics that will be covered include image-based quality control, automation of autonomous vehicles and robots, precision measurement technology, material flow digitalization and scalable, digital IIoT platforms. The consideration of increasingly important cybersecurity requirements and service offerings is an integral part of applications for sensor and system solutions.

As one of the most important international trade fairs, the annual SPS fair covers the entire spectrum of smart and digital automation solutions – from simple sensors to intelligent solutions, from the latest version of technology to the opportunities that are set to arise in the increasingly digitalized industries of the future. “As an automation partner that takes a holistic approach to the unique industrial environments of our customers, the SPS is the ideal platform to showcase our strength in intelligent automation and our cross-industry, innovative solution expertise to a broad specialist audience," says Tobias Güttler, Head of Marketing & Technology Competence Center at SICK Vertriebs-GmbH in Düsseldorf. “Visitors to our stand will be given an insight into our world in a friendly and informal setting, with advice and information being simply and conveniently targeted to their respective requirements.”

Image-based quality control

With its SICK Nova image processing platform, the company will demonstrate how vision solutions can be used to implement efficient quality control in consumer-related industries such as food and packaging technology. It is available for various 2D and 3D vision sensors from SICK, such as the InspectorP, Visionary, picoCam2 and midiCam2 product families with SIM (Sensor Integration Machine) or Ruler in the form of hardware-specific SensorApps. As a software basis with intuitive UX design and AI-supported Deep Learning, SICK NOVA makes it possible to simply and easily implement demanding applications for presence monitoring, quality control, and intelligent inspection, even without specialist knowledge.

Photo: SICK

Industrial robotics

With the PLB robot guidance system, SICK will present its innovative solution for flexible 3D part localization for the automated picking of objects from pallets or containers. With the help of 3D cameras, powerful software algorithms and artificial intelligence, PLB-guided robots can locate and grip randomly arranged small parts in a container just as reliably as it can grip boxes, assemblies or cast parts on a pallet or special load carrier. The software of the pre-calibrated 3D camera systems and the functions of the PLB can be easily integrated into the control of industrial robots in just a few minutes. Thanks to the Deep Learning function, the 3D camera systems are capable of learning, thus increasing the flexibility of use in changing bin-picking applications. The software's user interface can be easily configured and customized. Bin-picking applications can thus be implemented even more flexibly, efficiently and reliably.

Photo: SICK

Automation of autonomous vehicles

Intelligent collision avoidance and area monitoring with robust 3D image processing – this is what the VISIONARY AI Assist driver assistance system, set to be presented for the first time at SPS 2025, stands for. It consists of a smart Visionary-B Two 3D snapshot camera and the AI Assist software. Developed for harsh outdoor conditions, the measuring stereo camera system with 3D environmental perception capability warns of critical situations in the working area of mobile machines. AI Assist supplements route, side and rear area protection with the option of targeted person detection. This enables reliable and differentiated detection for prioritized warnings. VISIONARY AI Assist is an all-in-one solution – because the data processing and AI software are also fully integrated into the monitoring system, which can be configured using a web browser.

Photo: SICK

Material tracking in material flow

In both non-automated and semi-automated areas, detailed positions and movements of materials on load carriers and industrial trucks are used to keep track of all relevant material flow information. These help to evaluate and control the flow of goods. To ensure transparency and traceability in internal supply chains, SICK has a complete portfolio of identification and localization solutions. These are used at various points in the material flow. This means they cover the entire goods flow process – from goods receipt, storage and picking through to goods issue and dispatch. This guarantees complete control and transparency of the goods supply as well as facilitating optimized transport routes and minimized search times.

For example, the Ident Gate System uses a wide range of sensors to identify palletized goods that are marked with bar codes or 2D codes or with UHF RFID or hybrid tags. Seamless IT integration in the merchandise management system rounds off the concept. The Automated Load Detect Ident System (ALDIS) ensures the localization of forklift transport operations on the factory premises. It creates transparency and helps to simplify the growing complexity of intralogistics processes, while also facilitating accurate, flexible and cost-efficient localization and identification of goods. Intelligent sensors automatically detect loading and unloading processes of industrial trucks. The transport materials are automatically identified via bar codes, 2D codes or RFID. The combination of ultra-wideband (UWB) and GPS technology enables the global tracking of goods to their final site of deployment.

Photo: SICK

Scalable digital solutions

Scalable digital applications have become an integral part of today's industrial world. To provide its customers with even better support in the digitalization of processes and applications, SICK has developed an end-to-end and scalable IIOT platform. It combines efficient engineering, seamless OT-IT integration and data-based optimization. Engineering and programming tools help with application design, commissioning, maintenance and the entire life cycle management of the devices. In addition, data streams can be integrated securely, continuously and efficiently with solutions from SICK. They support a wide range of industrial fieldbuses and interface technologies. The application-specific solutions collect, analyze and visualize data from various sources. This allows data-based processes, such as machine availability or transparency in the material flow, to be optimized. The end-to-end approach across the entire life cycle reduces the complexity of digitalization processes. And thanks to the modular structure of the IIoT platform, the solutions adapt to individual challenges and can also be scaled for future tasks.

With the OD200, SICK will also present a measuring detection and distance sensor for short scanning ranges in a miniature design that can be used for such a data source. The sensor sets a new standard in its class with unprecedented measurement stability on highly reflective, black and irregular surfaces. With a newly developed measuring core with a high-resolution receiver line and an optimized optical system, the new distance sensor achieves a level of precision, linearity and repeatability that is otherwise only offered by high-end devices. As a result, the OD200 ensures high measured value stability and reliable, reproducible detection and switching behavior. This makes the distance sensor a convincing solution for a wide range of applications in various industries, including the automotive sector, consumer goods, electronics, mechanical and plant engineering.

Photo: SICK

www.sick.com