www.ptreview.co.uk

18

'25

Written on Modified on

Direct Drive vs. Geared Actuators

ALVA Industries outlines when to use direct drive for precision and dynamics, and when geared actuators deliver essential torque and compactness.

www.alvaindustries.com

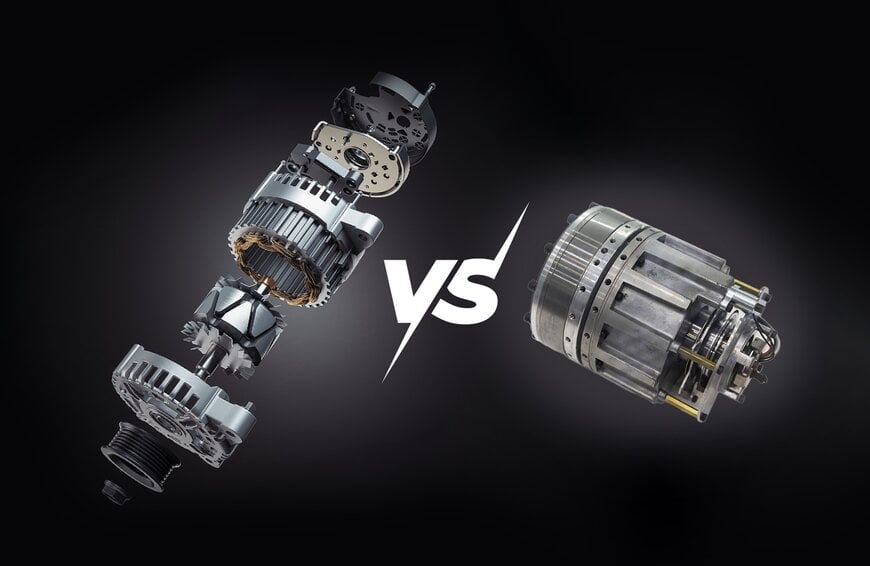

The question “Which is better: a direct-drive or a geared actuator?” has no one-size-fits-all answer, it depends on the application. All motor systems need to deliver torque and rotational speed, but specific requirements vary widely. Some applications demand low-speed output with precise excellent dynamic control, while others require maximum torque in the smallest form factor. In this article, we break down the key considerations to help you choose the right actuator for your needs.

Direct Drive for Dynamic & Precise Actuation

Advantages:

- No backlash

- No friction

- Low inertia

- Low to no cogging

- No compliance issues

- High Back-drivability

- High mechanical resolution

- High reliability

- Low to no maintenance

- No lubrication required for actuation

- Linearity over time

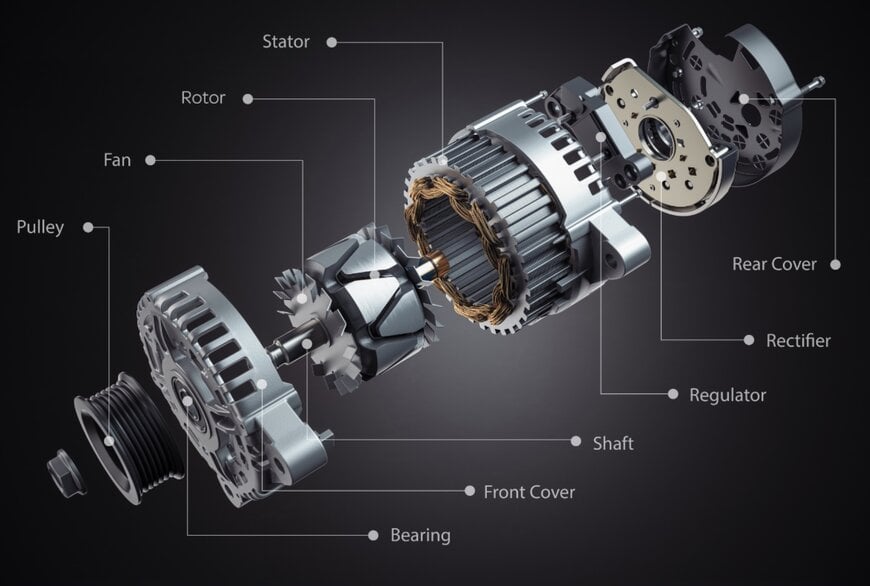

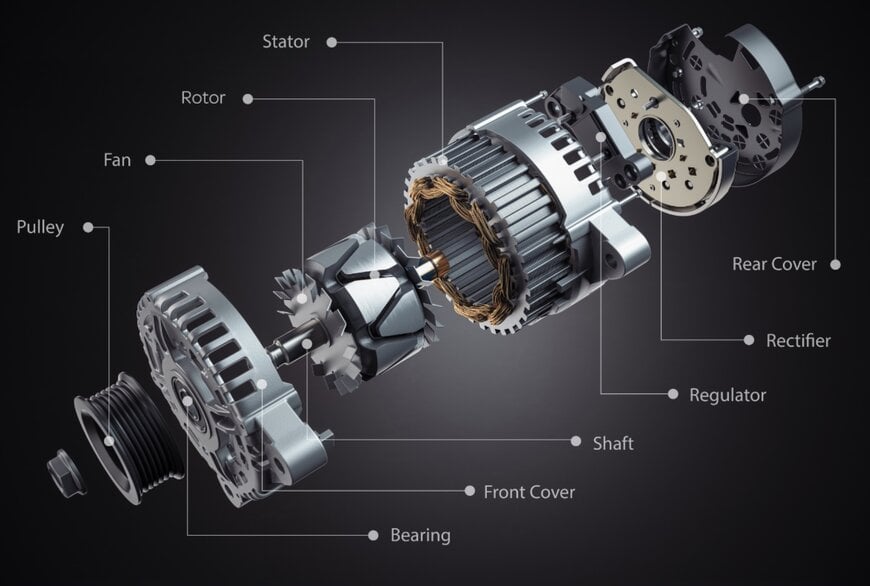

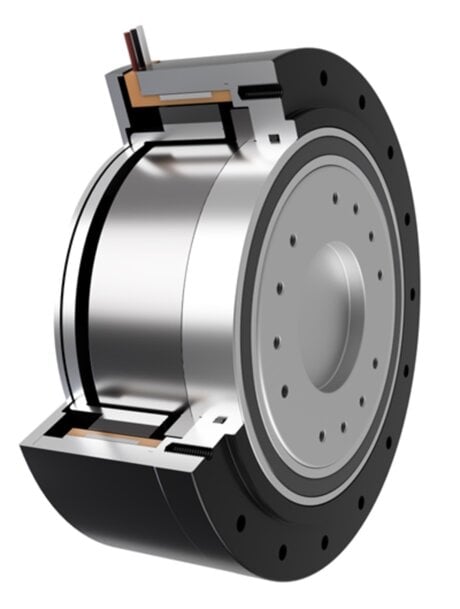

Direct drive motors are ideal for applications that require good control and dynamics. Figure 1 shows an example of a housed version, and Figure 2 shows examples of frameless Direct Drive motors. They have no backlash, no mechanical friction, virtually no compliance (very rigid) and low inertia. All these attributes improve the ability to control the position of the motor in a fast and confident manner.

Figure 1: Direct Drive configuration with housing and other components.

The backlash in geared actuators effectively diminish the ability to position the motor with high accuracy, and even with an output encoder the positioning accuracy will be limited, and the dynamic performance will be inferior. Only true direct drive actuators have zero backlash, “zero backlash gearboxes” still exhibit backlash in the form of hysteresis.

Figure 2: SlimTorq™ Frameless Direct Drive motors.

Mechanical friction and especially stiction introduce non-linearities into the system, complicating control tuning and reducing dynamic performance. Mechanical friction is particularly detrimental for stabilisation applications where the inertia of the system is used for filtering out high-frequency disturbances, e.g., in airborne optronics.

Compliance in an actuation system that requires good position control creates challenges. Compliance acts like an elastic, or even worse a plastic load transferring component. This will create a relative angle between the motor and the payload that is dependent on the output torque and make the system non-deterministic since it isn’t possible to model perfectly. As a result, it will impair the ability to tune the position control in an optimal manner.

Minimizing the inertia of the system is of the highest importance due to the linear relationship between torque and rotational acceleration. A reduction in inertia has a direct linear impact on the required torque and therefore the size and weight of the motor and the power consumption for actuation.

Direct Drive Applications

Direct drives are optimal for applications where fine and fast position and torque control are of highest importance. Typical examples of this are gimbals, force-feedback systems and metrology machines.

Gimbals and Optronic Systems

Gimbals require precise, repeatable and fast positioning under varying dynamic loads.

Typically, these systems hold a camera, laser or other optronic element that needs to locate objects and gather information with high precision over long distances. Even a small backlash in a geared system or cogging torque from slotted motors affects the precision dramatically.

These systems are also often mounted on aerial and other moving vehicles, which increases the need for fast and highly dynamic positioning and stabilization against unpredictable external forces.

Force-feedback systems

Force-feedback systems require realistic responses, which need to be both fast and accurate. Applications in this field could be different kinds of simulators, robotic surgery systems, virtual reality applications or different kinds of teleoperation robots for example. Generally, all these applications need to give the operator a sense of touch or emulate some real-world scenario. To improve this behaviour, the generated force or motion needs to happen instantaneously, and with the correct precision. Therefore, direct drive solutions are preferred, as they remove potential problematic phenomena such as backlash, friction, increased inertia, and gearbox cogging.

Metrology machines

Metrology machines require high precision, repeatable and smooth motion profiles. The more precise and stable they are, the better. Typical applications such as coordinate measuring machines, rotary tables and laser scanners tend to use direct drives to eliminate the backlash and other problems introduced by gears. Also, a direct drive will perform better due ro the minimization of rotating components, and reduction of the length of the system the motor needs to rotate.

Geared actuation for Torque & Compactness

Based on the advantages of direct drive actuators, one could assume that they can be used for all applications. Nevertheless, direct drive actuation has some limitations, making them unfit for some other use cases, mainly when the torque output required in a compact space is very high. Many applications require torque levels far exceeding the abilities of direct drive actuators or when budgets are limited. When torque output is of highest importance geared solutions are the best choice and in general, there are two main options to choose from: low gear-ratio actuators and high gear-ratio actuators. Which one is the right fit depends on several other factors. The following section addresses some of them.

Low gear-ratio actuators, QDD actuators

Advantages:

Figure 1: Direct Drive configuration with housing and other components.

The backlash in geared actuators effectively diminish the ability to position the motor with high accuracy, and even with an output encoder the positioning accuracy will be limited, and the dynamic performance will be inferior. Only true direct drive actuators have zero backlash, “zero backlash gearboxes” still exhibit backlash in the form of hysteresis.

Figure 2: SlimTorq™ Frameless Direct Drive motors.

Mechanical friction and especially stiction introduce non-linearities into the system, complicating control tuning and reducing dynamic performance. Mechanical friction is particularly detrimental for stabilisation applications where the inertia of the system is used for filtering out high-frequency disturbances, e.g., in airborne optronics.

Compliance in an actuation system that requires good position control creates challenges. Compliance acts like an elastic, or even worse a plastic load transferring component. This will create a relative angle between the motor and the payload that is dependent on the output torque and make the system non-deterministic since it isn’t possible to model perfectly. As a result, it will impair the ability to tune the position control in an optimal manner.

Minimizing the inertia of the system is of the highest importance due to the linear relationship between torque and rotational acceleration. A reduction in inertia has a direct linear impact on the required torque and therefore the size and weight of the motor and the power consumption for actuation.

Direct Drive Applications

Direct drives are optimal for applications where fine and fast position and torque control are of highest importance. Typical examples of this are gimbals, force-feedback systems and metrology machines.

Gimbals and Optronic Systems

Gimbals require precise, repeatable and fast positioning under varying dynamic loads.

Typically, these systems hold a camera, laser or other optronic element that needs to locate objects and gather information with high precision over long distances. Even a small backlash in a geared system or cogging torque from slotted motors affects the precision dramatically.

These systems are also often mounted on aerial and other moving vehicles, which increases the need for fast and highly dynamic positioning and stabilization against unpredictable external forces.

Force-feedback systems

Force-feedback systems require realistic responses, which need to be both fast and accurate. Applications in this field could be different kinds of simulators, robotic surgery systems, virtual reality applications or different kinds of teleoperation robots for example. Generally, all these applications need to give the operator a sense of touch or emulate some real-world scenario. To improve this behaviour, the generated force or motion needs to happen instantaneously, and with the correct precision. Therefore, direct drive solutions are preferred, as they remove potential problematic phenomena such as backlash, friction, increased inertia, and gearbox cogging.

Metrology machines

Metrology machines require high precision, repeatable and smooth motion profiles. The more precise and stable they are, the better. Typical applications such as coordinate measuring machines, rotary tables and laser scanners tend to use direct drives to eliminate the backlash and other problems introduced by gears. Also, a direct drive will perform better due ro the minimization of rotating components, and reduction of the length of the system the motor needs to rotate.

Geared actuation for Torque & Compactness

Based on the advantages of direct drive actuators, one could assume that they can be used for all applications. Nevertheless, direct drive actuation has some limitations, making them unfit for some other use cases, mainly when the torque output required in a compact space is very high. Many applications require torque levels far exceeding the abilities of direct drive actuators or when budgets are limited. When torque output is of highest importance geared solutions are the best choice and in general, there are two main options to choose from: low gear-ratio actuators and high gear-ratio actuators. Which one is the right fit depends on several other factors. The following section addresses some of them.

Low gear-ratio actuators, QDD actuators

Advantages:

- Back-drivability

- Low friction

- High torque output

- Higher speeds

- Dynamic reaction

- Higher efficiency

Actuators outfitted with low friction and high back-driveability gearboxes with gear-ratios up to 20:1 are sometimes called Quasi Direct Drive (QDD) actuators. They are called QDD because they mimic the properties of direct drive motors to a certain extent. QDD actuators are similar to true direct drive actuators in the sense that they have relatively low friction, high back-drivability and low inertia compared to actuators fitted with gearboxes with high gear-ratios.

The low gear-ratio allows QDD actuators to retain many of the advantages of a direct drive actuator and in addition to have greatly improved torque output. The torque output, compared to a direct drive actuator, increases virtually linearly with the gear ratio of a QDD actuator. The result is a very powerful actuator with sufficient dynamic performance for many applications. The ability to precisely and fast hit a position target is reduced, but this could be acceptable for most applications. Figure 3 shows an example of such actuator with an integrated gearbox inside the motor.

Figure 3: Neugart’s gearbox integrated inside a SlimTorq™ motor from Alva. Image credits: Neugart GmbH

Sustained back-drivability and relatively low inertia are crucial for applications that interact with unpredictable environments. For example, in legged robotic applications the leg will interact with uneven surfaces and need to be able to dampen sudden collisions which is only possible with high back-drivability and low reflected inertia.

Low gear-ratio applications

Low gear-ratio applications include systems where higher torque is required, and less precision can be tolerated. Typically, this could mean applications where maximum torque is required, but back-drivability still needs to be considered. For example, humanoids and quadruped robotics, exoskeletons and delta robots.

Humanoids & quadruped robotics

These robots have very dynamic load cases. They require compact and lightweight actuators, high holding torques, fast responses, and high peak torques. They also need to be back-drivable, both for safety in certain environments and to adapt to sudden external forces. The solution is usually to find an optimal, compact actuator with a low gear ratio that can handle different torque and speed operating points.

Exoskeletons

Exoskeletons are placed onto the bodies of humans. They therefore need to be compact, lightweight, back-drivable and of course strong to sufficiently help with the work being conducted. A low gear-ratio actuator is great for this combination of attributes. The actuator needs to both supply with sufficient torque and speed when needed but also needs to adapt quickly to the external forces generated, especially if it’s an assistive system.

Delta robots

A delta robot needs to be strong, fast and precise, a trade-off scenario which is suitable for a QDD-actuator. The robots need to have high responsiveness, high control bandwidth and still need to perform high accuracy operations. The low-gear actuator allows for reasonably high responsiveness, with increased torque capabilities.

High gear-ratio actuators

Advantages:

The low gear-ratio allows QDD actuators to retain many of the advantages of a direct drive actuator and in addition to have greatly improved torque output. The torque output, compared to a direct drive actuator, increases virtually linearly with the gear ratio of a QDD actuator. The result is a very powerful actuator with sufficient dynamic performance for many applications. The ability to precisely and fast hit a position target is reduced, but this could be acceptable for most applications. Figure 3 shows an example of such actuator with an integrated gearbox inside the motor.

Figure 3: Neugart’s gearbox integrated inside a SlimTorq™ motor from Alva. Image credits: Neugart GmbH

Sustained back-drivability and relatively low inertia are crucial for applications that interact with unpredictable environments. For example, in legged robotic applications the leg will interact with uneven surfaces and need to be able to dampen sudden collisions which is only possible with high back-drivability and low reflected inertia.

Low gear-ratio applications

Low gear-ratio applications include systems where higher torque is required, and less precision can be tolerated. Typically, this could mean applications where maximum torque is required, but back-drivability still needs to be considered. For example, humanoids and quadruped robotics, exoskeletons and delta robots.

Humanoids & quadruped robotics

These robots have very dynamic load cases. They require compact and lightweight actuators, high holding torques, fast responses, and high peak torques. They also need to be back-drivable, both for safety in certain environments and to adapt to sudden external forces. The solution is usually to find an optimal, compact actuator with a low gear ratio that can handle different torque and speed operating points.

Exoskeletons

Exoskeletons are placed onto the bodies of humans. They therefore need to be compact, lightweight, back-drivable and of course strong to sufficiently help with the work being conducted. A low gear-ratio actuator is great for this combination of attributes. The actuator needs to both supply with sufficient torque and speed when needed but also needs to adapt quickly to the external forces generated, especially if it’s an assistive system.

Delta robots

A delta robot needs to be strong, fast and precise, a trade-off scenario which is suitable for a QDD-actuator. The robots need to have high responsiveness, high control bandwidth and still need to perform high accuracy operations. The low-gear actuator allows for reasonably high responsiveness, with increased torque capabilities.

High gear-ratio actuators

Advantages:

- Highest torque output

- Holding torque (No power needed)

- High precision

- Low backlash

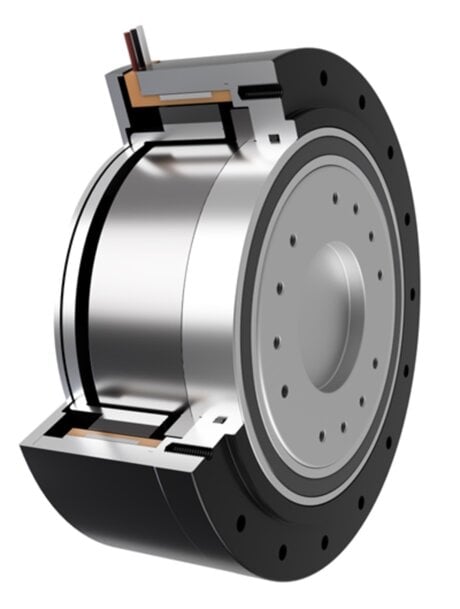

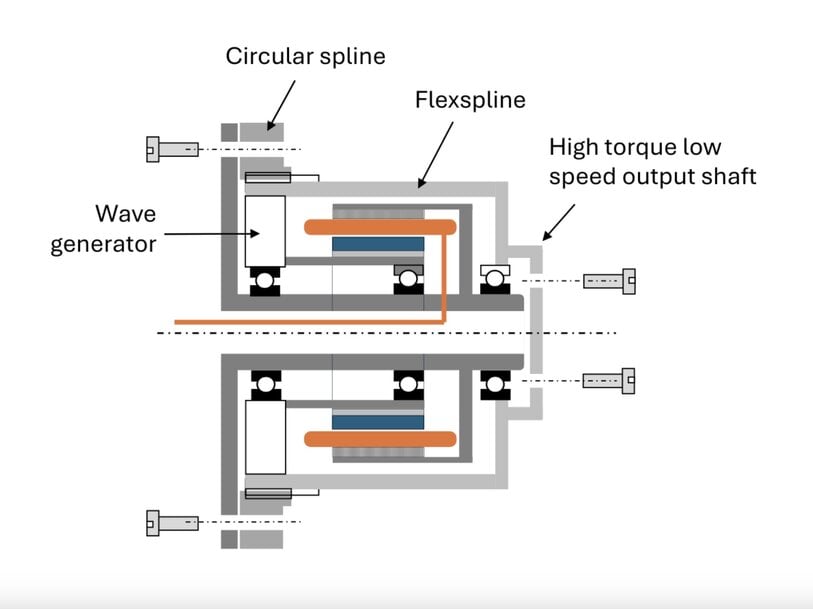

Sometimes the need for high levels of torque far exceeds the potential of direct drives and even QDD actuators. In those cases, a high gear-ratio actuator is the right solution. The high gear-ratio enables extremely high torque levels, well beyond direct drive and QDD actuators, from compact actuators. However, the high torque output may introduce some drawbacks. The high gearing dramatically increases friction, which effectively diminishes back-drivability to zero and massively increases reflected inertia, rendering the system unable to dampen external forces. The lack of back-drivability can also be an advantage, e.g., in applications that require high static holding torque. Such an actuator can be extremely compact, as shown in the sketch in Figure 4, where the motor is integrated inside the high-gear-ratio gearbox.

Figure 4: Concept sketches of motor integration inside a gearbox: in-runner motor.

High gear-ratio applications

For high gear-ratio applications, the focus is to achieve high enough torque, in a fixed space or weight budget. Typically, these systems focus on low-speed operating points and do not require joints to be highly back-drivable. This includes industrial robots, medical robotics, and machinery actuation across several industries.

Industrial robot arms

Robot arms carry out heavy load movements, with high enough speed and precision. The weight of the payload is usually the more important aspect, and speed and precision are secondary. These high-geared robot actuators, which are placed in the joints, need to carry high loads while having a compact size, and the small motors are therefore coupled with a high gear-ratio transmission.

Cobots

Cobots are like robot arms, but they operate either in environments along humans, or even with the contribution of human movements. The task could be to aid in a heavy load operation, or simply to take on a work operation in the same working environment as humans. Even though a back-drivable joint would be beneficial, load-handling capability is typically considered more important, and system speed is reduced to accommodate a safer design.

Figure 4: Concept sketches of motor integration inside a gearbox: in-runner motor.

High gear-ratio applications

For high gear-ratio applications, the focus is to achieve high enough torque, in a fixed space or weight budget. Typically, these systems focus on low-speed operating points and do not require joints to be highly back-drivable. This includes industrial robots, medical robotics, and machinery actuation across several industries.

Industrial robot arms

Robot arms carry out heavy load movements, with high enough speed and precision. The weight of the payload is usually the more important aspect, and speed and precision are secondary. These high-geared robot actuators, which are placed in the joints, need to carry high loads while having a compact size, and the small motors are therefore coupled with a high gear-ratio transmission.

Cobots

Cobots are like robot arms, but they operate either in environments along humans, or even with the contribution of human movements. The task could be to aid in a heavy load operation, or simply to take on a work operation in the same working environment as humans. Even though a back-drivable joint would be beneficial, load-handling capability is typically considered more important, and system speed is reduced to accommodate a safer design.