Nabtesco Cycloidal Gears Deliver Precision for Heavy-Duty Applications

Nabtesco’s compact cycloidal gears handle 70,000 Nm with 0.01mm precision, serving robotics and heavy industry through custom drive solutions.

www.nabtesco.com

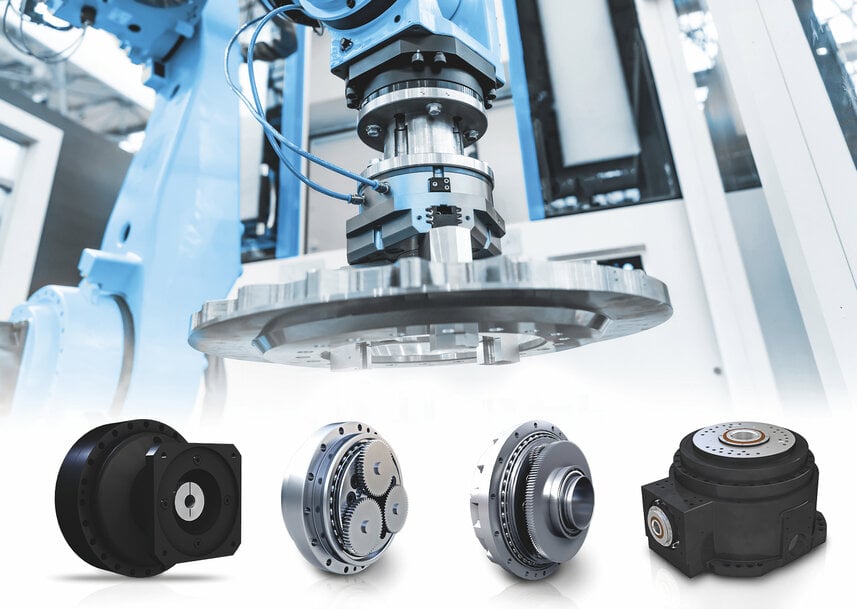

For precision applications with heavy loads, Nabtesco offers an extensive product portfolio of compact high-performance cycloidal gears in graduated sizes. The innovative gear systems are exceptionally powerful, durable, and reliable, to assure efficient pin-point positioning even in the most demanding applications. An ideal solution for high torques and heavy loads.

Heavy loads are often moved by means of hydraulic systems or large planetary gears. However, cycloidal gears are clearly superior in most cases. Their special design principle enables very high reduction ratios with only two to three gear stages, which guarantees precise and reliable positioning within a hundredth of a millimetre in an extremely compact design. Nabtesco, the world’s largest manufacturer of precision cycloidal gears and world market leader in the area of robotic gears with more than 35 years of experience, knows the specific challenges of heavy-duty applications and implements robust and efficient gear and drive solutions.

Robust cycloidal gears for precise positioning of heavy loads

Cycloidal gears use cams and rollers for power transmission. This design ensures virtually full contact and even distribution of forces within the gearbox, which produces high rigidity. As a result, it is possible to transmit very high torques with maximum precision and smooth operation. The increase in backlash is infinitesimal, even over long periods (hysteresis loss < 1 arcmin, purely mechanical backlash 0.1–0.2 arcmin). In addition, minimum wear operation ensures a long service life. The integrated angular ball bearings absorb both axial and radial loads and bending moments, and provide for high moment rigidity and resistance to impacts and overloading (up to 500 % of the rated torque). By the way: In cycloidal gears, the efficiency improves as the load increases. The reason: Higher torque results in higher rigidity. Rigidity reduces elasticity in the gear, which causes an increase in efficiency.

Exceptional performance up to 70,000 Nm

Whether in robotics, mechanical engineering or other high-tech industries: Wherever exact positioning and absolute reliability are required, Nabtesco gears are the first choice. The product portfolio ranges from highly integrable component sets, compact gear units, and dynamic servo gearboxes to powerful rotary indexers and covers a torque spectrum up to 70,000 Nm. The following series are especially suitable for use in heavy-duty applications: Neco®HT (modular high-torque gears), RV-N (solid shaft robotic gears), RV-C (hollow shaft robotic gears) and RS (hollow shaft rotary indexers). The product range also includes the world’s largest precision gearbox (RV-2800N) and the world’s largest plug-and-play precision gearbox (Neco® HT-900).

Wide range of heavy-duty applications

Nabtesco cycloidal gears are designed for high torques and heavy loads and have proven themselves a million times over in countless heavy-duty applications. Heavy-duty positioners (large head and tailstock positioners, “L” and “H” positioners) benefit from the specific properties of the heavy-duty solutions, as do machine tools (e.g. machining centres for large gearwheels, feeder systems for large, heavy parts, tower drilling centres for wind turbines), production plants (such as “big wheel” refrigerator production, extrusion blow-moulding machines) and industrial automation (handling of large glass panes, metal sheets, heavy machine parts, or entire vehicles).

Highest service level

In cooperation with the customer the company implements custom drive solutions that are perfectly adapted to the particular challenge. The all-inclusive concept at Nabtesco is unique. The cycloidal gear specialist offers full-service support and assistance with all aspects of gears and drive systems – from initial consultation to selection and design, as well as production and maintenance. This allows customers to concentrate wholly on their core competences. The high production capacity of over 1 million gear units per year – with a goal of 2 million per year by 2030 –, highly automated production processes, and 100% quality control prior to delivery guarantee maximum safety and availability.

www.nabtesco.com