www.ptreview.co.uk

04

'24

Written on Modified on

ASC Sensors presents Robotic multi-sensor platform for precise 3D modeling

Since 1996, Vienna-based DGNSS Sensors GmbH uses mobile 3D laser scanning platforms to precisely map interiors, buildings, and landscapes with advanced sensors and imaging devices.

www.asc-sensors.de

With the help of a Robot Operating System (ROS), the various digital data is integrated in real time to create a realistic, three-dimensional image of the surveyed environment – a digital twin. On board the latest measuring platform: inertial accelerometers from ASC.

High-resolution 3D models for Building Information Management

“Our measurement platform is used in a range of applications,” says Heinz Stanek, PhD, Senior Consultant and Product Developer at DGNSS. “Laser scanning and Building Information Modeling (BIM) are powerful technologies of increasing value in the construction, maintenance and efficient use of buildings.”

They provide a reliable basis for the creation of 3D models of buildings, infrastructure projects and other facilities. These photorealistic models enable the operator to create a detailed virtual representation of the real-world building or site and serve as a starting point for further planning and development. At the same time, this allows for the timely scheduling of required maintenance and helps optimize building management.

High-resolution point clouds in black and white or color enable the precise geometric recording of the existing object as a basis for further analyses and modeling processes. “We integrate the captured data into a BIM model that contains detailed information about the physical and functional characteristics of the object,” Stanek explains. These BIM models enable comprehensive collaboration between all parties involved in the construction project and, therefore, its efficient planning and execution.

Inertial ASC sensor put to the test

However, even the best surveying technology is only ever as good as its individual components. That is why DGNSS is constantly refining its robotics platform. To be able to guarantee the highest standards of measurement accuracy, stability, data transmission and analysis compatibility, the company relies on its own internally developed methods as well as reliable partners.

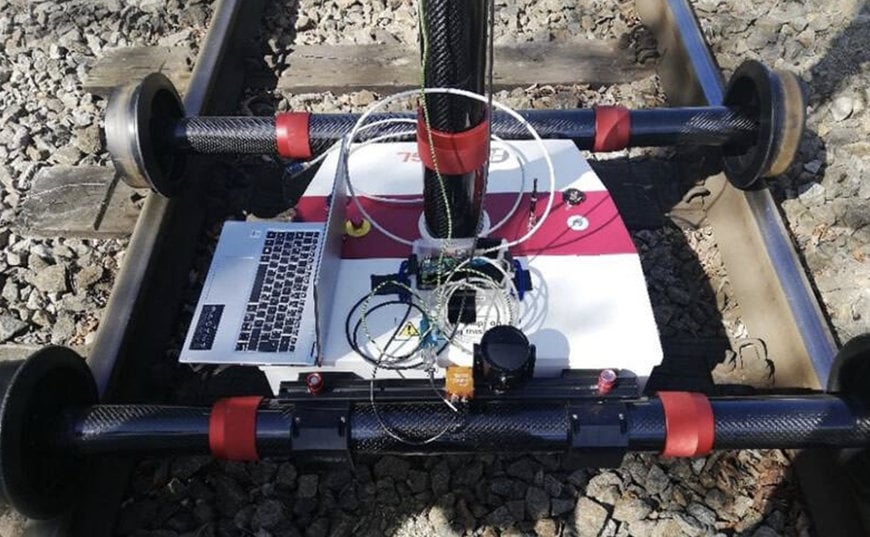

In a special cooperation to model track corridors and railroad infrastructure components, the multi-sensor measuring platform is mounted on a rail-bound hand-rail trolley that stops every seven meters in stop & go mode to record 20 million measurement data plus high-resolution calibrated photos per minute. The digital ASC DiSens® ECO accelerometer is used to determine and transmit relative positioning, relevant track parameters and redundant quality checks.

In order to validate its suitability for this project and fundamental compliance with the DGNSS robotic multi-sensor platform, the digital ASC acceleration sensor recently underwent a rigorous test series at the Department of Geodesy and Geoinformation at Vienna University of Technology. This included static long-term testing in the laboratory (gravity acceleration, recording rate, standard deviation, temperature stability, step response, etc.), practical application tests at the Großglobnitz research station with a 2 km track system of its own, as well as compatibility evaluation of the sensor technology with the ROS data integration system used.

The experts’ conclusion: The ASC DiSens ECO is generally suitable for integration in multi-sensor systems due to its outstanding accuracy, low standard deviation in all operating modes, its robustness, step response, convenient data transmission and compatibility.

Joint research and application – compatible solutions

“In recent years, not only have we significantly expanded our expertise in the use of laser scanners as such,” states Stanek. “Continuous improvements made to the underlying ecosystem, too – for example, the precise control and positioning of our robotic platforms and track trolleys on all kinds of surfaces, terrain and environmental conditions – allow us to design the scanning process efficiently and accurately.”

As the demand for high-precision multi-sensor technology is constantly on the rise. “While ASC is able to cover part of this directly through innovative, cost-effective sensor solutions of our own, we are always happy to collaborate on research and application,” says Renate Bay, Managing Director of ASC Sensors. “After all, the customer is only helped if the various technologies used ‘speak a common language’, sensor systems communicate and their data can be linked in a meaningful way. In complex scenarios, added value is only generated through a successful overall solution – not powerful individual components alone.”

www.asc-sensors.com