Delta Revolutionizes Drawer Track Assembly Through Advanced Automation Solutions

The implementation of SCARA robots and the AX-8 PC-Based Motion Controller has enhanced ATS' operational efficiency and demonstrated Delta's unique market position.

Delta's innovative automation solutions have significantly transformed the production capabilities of ATS srl., a leading system integrator for complete automatic lines. This collaboration, featuring the implementation of SCARA robots and the AX-8 PC-Based Motion Controller, has enhanced ATS' operational efficiency and demonstrated Delta's unique market position.

ATS srl., based in Jesi, Ancona, Marche in Italy, specializes in designing and implementing complete automatic lines, including electrical panels, machine boards, and software. With around 30 employees, ATS recently embarked on a project to develop an assembly machine for drawer tracks—a task requiring high precision and efficiency. The machine needed to automatically assemble drawer tracks by inserting three distinct pieces, achieving a final product without human intervention. Given the high demand for drawer tracks, ATS sought a solution that could significantly boost production while ensuring reliability and ease of use. Delta's advanced automation technologies provided the perfect fit for this challenge.

Innovative Automation with Delta's SCARA and AX-8 PC-Based Motion Controller

The collaboration between Delta and ATS commenced approximately six months before the commissioning phase. Delta introduced its SCARA robot solution, which ATS, already familiar with Delta’s extensive product range, was eager to test.

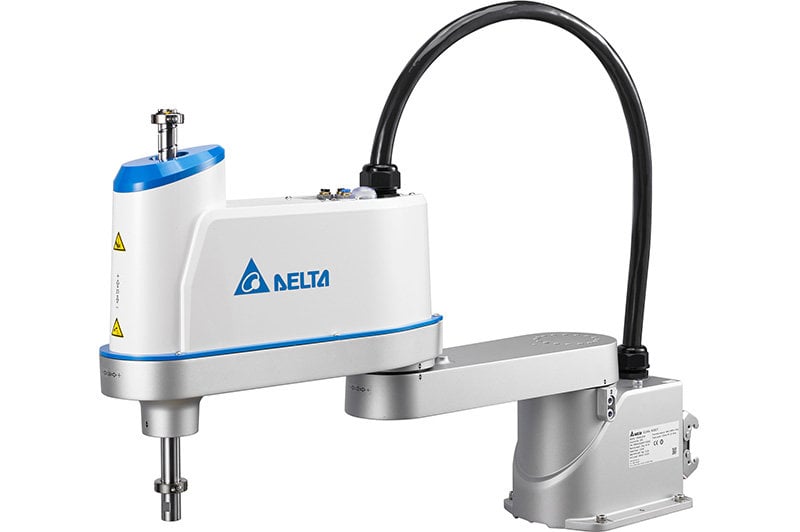

Delta’s comprehensive automation package included an Ethernet Switch (DVS-008), a Human Machine Interface (DOP-110), the AX-816 PC-Based Motion Controller, ASDA-B3 and ASDA-A2 series servo drive systems (ASD-B3A-E and ASD-A2E), SCARA robots (DRS40 for soldering the final pieces and DRS60 for forming drawers), and AC Motor drives (MS300). These components formed an integrated control system architecture for the assembly machine, enabling seamless and efficient operation.

Overcoming Challenges and Achieving Seamless Integration

Introducing Delta's SCARA robots marked a significant milestone for ATS, as it was their first experience with robotic automation from Delta. The main challenges were helping the customer to get comfortable with the new system and showcasing its efficiency in real-time. Delta’s team, comprising Project Managers and Field Application Engineers, provided extensive training sessions to ensure ATS’ team was proficient in using the new technology.

The project progressed smoothly thanks to Delta's robust training and support framework. The SCARA robots were successfully integrated into the assembly line, and the machine began to function as intended, producing drawer tracks with minimal human intervention.

Remarkable Results and Enhanced Production Efficiency

The results of this collaboration were outstanding with ATS experiencing a 40% increase in production efficiency. The AX-816 controller’s capability to coordinate multiple robots simultaneously further streamlined the assembly process, reducing cycle times and enhancing overall productivity.

The ease of programming and the remote connectivity features of the AX-816 controller were particularly beneficial. ATS could now perform remote diagnostics and assistance, ensuring minimal downtime and quick resolution of any issues that arose.

By leveraging Delta’s cutting-edge automation solutions, ATS has set a new benchmark in the assembly of drawer tracks, demonstrating the immense potential of integrating advanced robotics and control systems in industrial applications.

Delta’s unwavering dedication to problem-solving and customer support, combined with ATS’ operational excellence and strategic insights, has forged a formidable partnership. This collaboration stands as a beacon of success in the automation industry, providing a model for others navigating the complexities of modern manufacturing.

www.delta-emea.com