www.ptreview.co.uk

25

'24

Written on Modified on

MATERIALISE AND NTOP PARTNER TO PUSH THE BOUNDARIES OF WHAT’S POSSIBLE WITH ADDITIVE MANUFACTURING

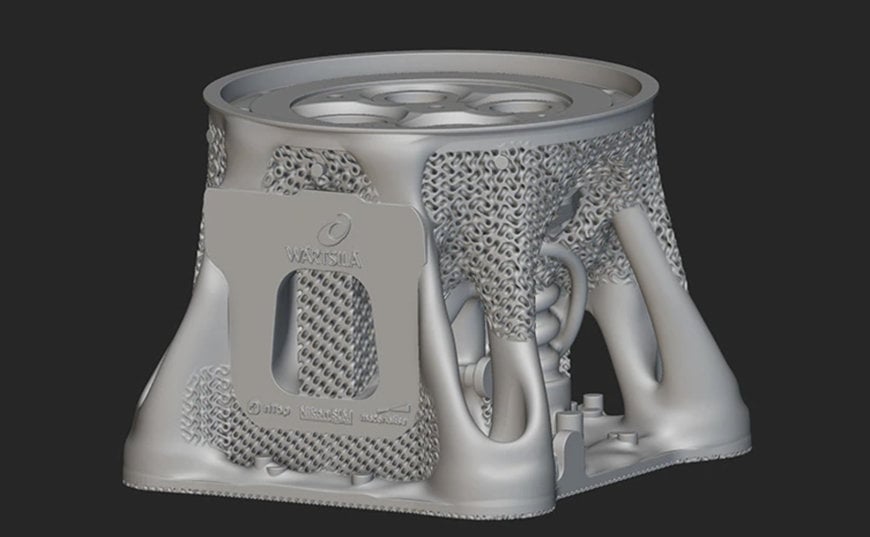

The collaboration yields high-performance 3D-printed cylinder head for Wärtsilä with enhanced cooling and 60% weight reduction.

Materialise and nTop have announced a pioneering collaboration to push the boundaries of what’s possible with additive manufacturing (AM). The integration of nTop Core, nTop’s implicit modeling API, with Materialise's Magics 3D Print Suite and NxG Build Processor, will allow manufacturers to accelerate the entire design-to-manufacturing process and enable the production of complex parts that were previously impossible to print. This collaboration has already demonstrated success in producing a high-performance, 3D-printed cylinder head for Wärtsilä, significantly enhancing cooling performance and reducing weight by 60%, which was printed by Nikon SLM Solutions.

This partnership solves a common problem for complex, high-performance designs by enabling implicit design files to be exchanged between design and manufacturing teams and natively processed for production without meshing or other intermediate processes. In turn, this allows engineering teams to design higher-performance parts with more features and capabilities while assuring they can be produced precisely and economically.

nTop has developed a powerful new implicit modeling kernel and corresponding file format that can characterize highly complex, high-performance geometries at a fraction of the size of traditional CAD or mesh-based files. Until now, high-performance product designs created in nTop could not be natively processed by Magics, requiring time-consuming translations for build preparation and production. Materialise’s NxG Build Processor is configurable software that translates large and complex 3D design files into 3D printable instructions, optimizing and managing the 3D printing process from start to finish. By integrating nTop’s design software with Materialise’s Magics and NxG Build Processor, these designs can be easily transferred natively to Materialise Magics for fast, high-quality build preparation and slicing.

3D printing the impossible: innovative 3D-printed cylinder head for Wärtsilä

Materialise and nTop collaborated with Nikon SLM to produce a high-performance cylinder head for Wärtsilä, a manufacturing company in the marine and energy markets. Wärtsilä explored innovative designs to optimize the cooling performance of the cylinder head, achieving a 60% weight reduction compared to the original design. This new design also allowed the integration of up to ten subsystems into the final component, reducing assembly complexity and improving cooling performance. Previously, the design complexity and file size of this innovative design made it impossible to 3D print the part using conventional large-scale AM technologies. However, by combining nTop’s design software with Materialise’s Magics and NxG Build Processor, based on implicit modeling, it became possible to 3D print the part. The final design was printed in Inconel 718 by Nikon SLM, using the largest metal printer on the market.

www.materialise.com