www.ptreview.co.uk

01

'24

Written on Modified on

HONEYWELL TO DRIVE DISTRIBUTION CENTER EFFICIENCY THROUGH COLLABORATION WITH HAI ROBOTICS

The alliance will help companies optimize space and increase productivity in fulfilling customer orders.

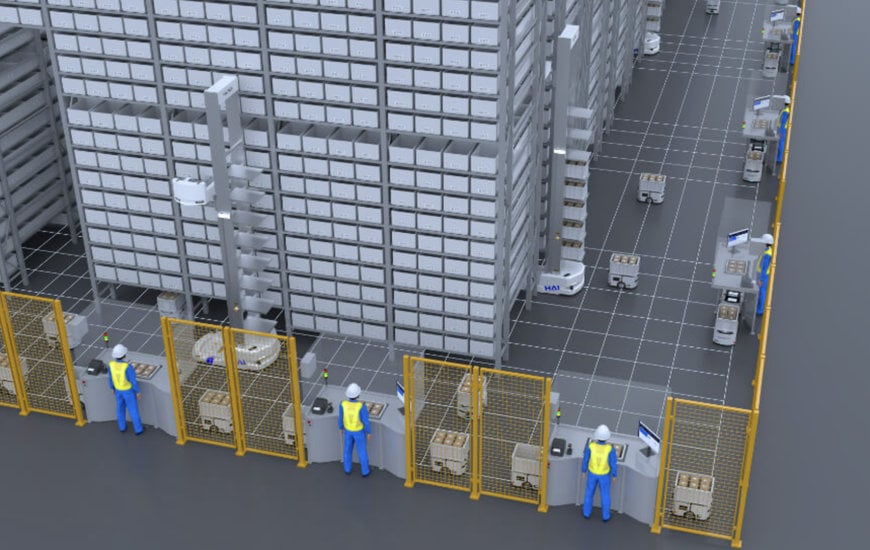

(Photo: Hai Robotics)

Honeywell announced it will team up with Hai Robotics to deliver flexible, high-density storage and retrieval solutions to distribution centres (DCs). The alliance couples Hai’s innovative robotics technology with Honeywell’s Momentum Warehouse Execution Software, enhanced cybersecurity capabilities and experience integrating robotics solutions.

Hai Robotics’ autonomous case- and tote-handling mobile robotics (ACR) solutions, which automate item storage and retrieval and make the warehouse put-away and picking processes more efficient, use guided robots capable of reaching up to 32 feet high. These systems condense the required footprint to store goods and can operate within existing brownfield DC and warehouse sites, as well as in the back of retail stores for micro-fulfillment.

The ACR solutions store a variety of cases, totes, moving pallets and shelves, and can support e-commerce, automotive, third-party logistics and manufacturing operations. Hai robots can increase productivity by achieving typical throughput rates of approximately 500 pieces per hour (pph), compared to 100-250 pph without the use of robotics.

Hai Robotics solutions integrate with Honeywell’s Momentum Warehouse Execution Software, enabling DC operators to analyze real-time operating information across a DC and prioritize and redirect work as it is performed by both robotic systems and people, allowing for reduced costs and greater customer service levels.

Honeywell announced it will team up with Hai Robotics to deliver flexible, high-density storage and retrieval solutions to distribution centres (DCs). The alliance couples Hai’s innovative robotics technology with Honeywell’s Momentum Warehouse Execution Software, enhanced cybersecurity capabilities and experience integrating robotics solutions.

Hai Robotics’ autonomous case- and tote-handling mobile robotics (ACR) solutions, which automate item storage and retrieval and make the warehouse put-away and picking processes more efficient, use guided robots capable of reaching up to 32 feet high. These systems condense the required footprint to store goods and can operate within existing brownfield DC and warehouse sites, as well as in the back of retail stores for micro-fulfillment.

The ACR solutions store a variety of cases, totes, moving pallets and shelves, and can support e-commerce, automotive, third-party logistics and manufacturing operations. Hai robots can increase productivity by achieving typical throughput rates of approximately 500 pieces per hour (pph), compared to 100-250 pph without the use of robotics.

Hai Robotics solutions integrate with Honeywell’s Momentum Warehouse Execution Software, enabling DC operators to analyze real-time operating information across a DC and prioritize and redirect work as it is performed by both robotic systems and people, allowing for reduced costs and greater customer service levels.

www.honeywell.com