www.ptreview.co.uk

03

'23

Written on Modified on

New NSK ball screws take the spotlight at EMO 2023

EMO Hannover 2023 (18-23 September) will provide NSK with a platform to showcase its latest advances in this important technology area. Notably, the company’s 120 m2 booth (Booth C42, Hall 7) will shine the spotlight on several ball screws making their exhibition debut in Europe.

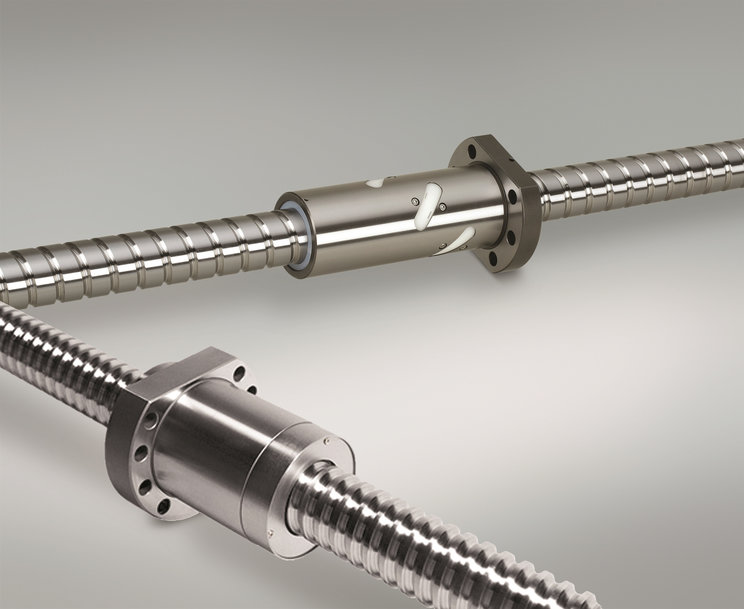

From milling, drilling and turning, to grinding, EDM and bending, machine tool processes are only as good as their component parts. For many decades the inherent quality and performance of NSK ball screws have met machine tool requirements for speed and precision, while generating low noise and minimising energy consumption.

Among the new ball screws will be NSK’s next-generation offer for high-accuracy machine tools. With reduced motion errors and the absence of ‘second glitch’ phenomenon, NSK next-generation ball screws improve productivity through higher quality surface finish, namely by reducing or eliminating the need for secondary polishing/burnishing operations in mould and die machining and other high-accuracy applications. In addition, a reduction in drive torque delivers important energy savings.

NSK next-generation ball screws offer near-elimination of the second quadrant glitch peak, in turn eradicating the need for compensation through parameter adjustment. In fact, reducing friction fluctuation by up 20% also contributes to reducing the height of the first peak.

A further new offer on the booth will be NSK’s low-temperature ball screws. Features of this innovative product include friction loss/heat generation that is some 45% lower than conventional systems at the same rigidity, helping users to maintain positioning accuracy. The new low-temperature ball screws also contribute to reduced energy consumption by lowering or eliminating the need for cooling. As a further benefit, the product offers approximately 65% less dynamic preload torque than conventional products at the same stiffness.

Yet another new ball screw at the show will be the company’s HFT super-long life series for high-load drive applications. This innovative product series offers up to double the life of conventional ball screws, thanks largely to the optimisation of load distribution in different areas of the ball circuit. Delivering resource conservation through long life and machinery downsizing, this super-long life series is perfect for machine tools shifting to all-electric designs, such as injection moulding machines and servo presses.

At EMO, NSK will complement its HTF super-long life series with the S-HTF range, which leverages the company’s proprietary Tough Steel to benefit applications subject to high loads and contamination. Offering approximately 2.2 times more fatigue life and up to 1.8 times higher load-carrying capacity than conventional solutions, the series is the world's first ball screw application involving Tough Steel technology.

Elsewhere on the booth, NSK is set to promote its high-durability ball screws, which feature a specific surface treatment on the raceway that supresses wear to realise longer maintenance intervals, even in short-stroke applications. The company will also display its high-speed, low-noise compact ball screws conforming to DIN-standard size requirements, ensuring dimensional and tolerance class suitability in European machine tool applications.

Another focus area at EMO will be linear guides, notably the new DH/DS long-life series, which delivers over twice the running distance of the company’s conventional NH/NS solution. NSK will also present its established RA series roller guides with highly dust resistant seals to prevent contaminant ingress.

NSK bearings on display at EMO will include the company’s ROBUSTDYNA ultra-high speed, high-load capacity angular contact ball bearings. Appearing for the first time in Europe, the use of larger bearing balls boosts maximum load capacity by up to 15% against the previous-generation solution.

Yet another introduction at the show will be NSK’s ROBUSTGRD grease, which enhances seizure-resistance to support use in high-speed spindle bearings.

Visitors will also discover the SURSAVE (TSR) bearing cage for angular contact ball bearings that reduces energy consumption, running temperature, vibration and noise during use on machine tool spindles. A range of NSK super precision bearings and high-speed motor bearings will complete the line-up for machine tools, alongside thin angular contact ball bearings for robots.

1) NSK S-HTF series is the world’s first ball screw application involving Tough Steel technology

2) NSK high-durability ball screws feature a special surface treatment on the raceway that supresses wear

3) NSK DIN-standard ball screws ensure dimensional and tolerance class suitability for European machine tool applications

4) The new NSK DH/DS series delivers over twice the running distance of the company’s conventional NH/NS linear guides

5) NSK’s new ROBUSTDYNA bearings use larger bearing balls that boost maximum load capacity by up to 15%